Crane slewing bearings & excavator slewing bearings slewing bearings

-

Supplier: Wuxi Nengli Bearing Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Nancy Fan -

Price: $100.00 / >=100 pieces -

Min. Order: 100 pieces

| Material: | Slewing ring bearing steel | OEM: | usable |

| Package preview: | model: | Slewing bearings | |

| type: | Slewing ring | Supply capacity: | 50,000 pieces per week |

| brand: | Hydraulic Management (OEM) | Seal type: | Oil seal |

| payment terms: | L/C, Western Union, T/T, PayPal | feature: | Four points of contact |

| Applicable industries: | Construction Engineering, Energy and Mining | Packaging details: | 1. Industrial packaging: plastic bag + kraft paper + carton + plywood pallet; plastic tube + carton + plywood pallet 2. Commercial packaging: 1 piece/plastic bag + color box + carton + plywood pallet 3. According to customer requirements |

| quality: | High quality slewing ring bearings | application: | Railway cranes, manned lifts, wind turbines, excavators, etc. |

| Gear options: | External gear only | port: | Shanghai&Shenzhen |

| Place of origin: | Jiangsu, China |

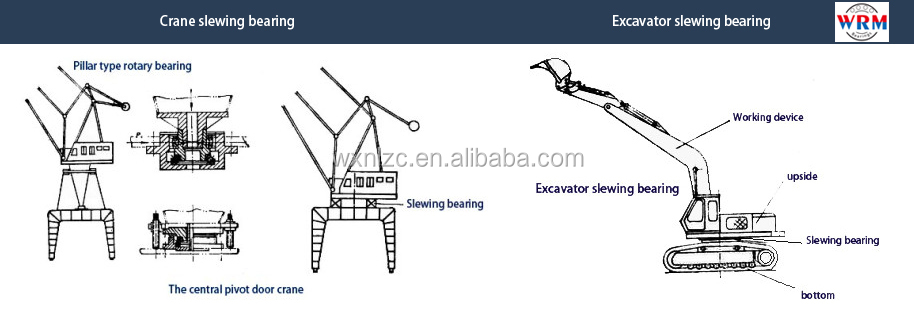

Crane slewing bearing, excavator slewing bearing

Available in different sizes and models

We can also provide OEM services according to your requirements.

There are many types and models of bearings, and the pictures are not necessarily actual pictures of the products. If you are interested, please contact us. We will go to the warehouse to take real photos for you and try our best to meet your requirements.

1. We can change the color of the rubber seal according to your actual requirements.

2. Customize the mark according to your requirements.

3. Choose different packages according to your needs.

Slewing bearings and wheel bearings are also called:Slewing ring, slewing ring bearing or slew bearing.

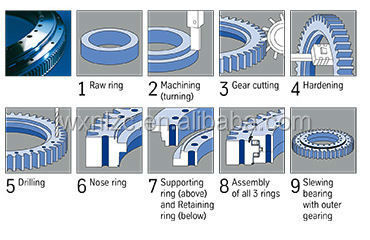

Slewing bearings are a new type of mechanical parts that have emerged worldwide in the past 40 years. They are composed of inner and outer rings, rolling elements, etc. At present, the final production of slewing bearings in my country was mainly researched by Tianjin Machinery Industry of the Ministry of Communications in the early 1980s. The Engineering Machinery Group of the institute has introduced the design and manufacturing technology of the former Federal German company Rothe Aid. The machinery industry standard of the People's Republic of China: JB/2300-2300 "Slewing Bearing Types, Basic Parameters and Technical Requirements" released on December 20, 1984, is mainly composed of the Tianjin Engineering Machinery Research Institute of the Mechanical and Electronic Industry, Xuzhou Hailin Slewing Bearing, etc. The factory was responsible for drafting, and the country subsequently released the construction machinery standard: JB36.1-36.3-91 in 1991. In 1999 and 2011, it released new machinery industry standards JB/2300-2300 and JB/2300-2011.

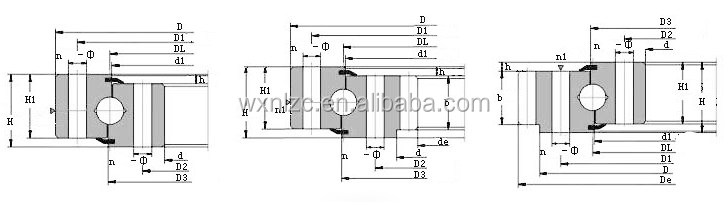

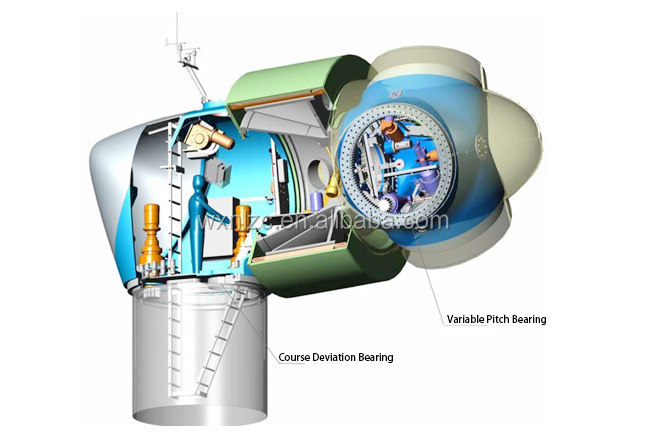

The slewing bearing is a bearing that can withstand large comprehensive loads and can withstand large axial, radial loads and tilting moments. Slewing bearings are generally equipped with holes, grease holes and sealing devices on the gears or gears, which makes the main engine design compact, simple to guide and easy to maintain. Slewing bearings have teeth, teeth and teeth with four-point contact ball bearings, double row angular contact ball bearings, crossed cylindrical roller bearings, crossed tapered roller bearings and triple composite bearings, four-row cylindrical roller series, including four-point contact balls The bearing has a high static load capacity, and the crossed cylindrical rollers have a high load capacity. Preloading can make the crossed tapered roller bearings have great support stiffness and rotation accuracy. The combined height of the three-row cylindrical roller bearings is due to Increased load-carrying capacity. Various powers of the bearings are borne by different races. Therefore, under the same stress distribution, the bearing diameter can be significantly reduced, thereby making the characteristics of the main machine more compact. It is a high load-bearing capacity rotary Support bearings. Slewing bearings are widely used in large slewing devices such as hoisting machinery, mining machinery, construction machinery, port machinery, ship machinery, and mechanical precision radar and missile launch equipment. At the same time, we can also design, develop and produce various special structure slewing bearings according to the specific requirements of customers.

The slewing bearing usually consists of a worm, a slewing bearing, a housing, a motor and other components. Since the core part uses a slewing bearing, it can bear axial force, radial force and overturning moment at the same time. There are many forms, but the structure is basically the same. From left and right they are (parts): 1. Outer ring (toothed or toothless) 2. Sealing tape 3. Rolling element (ball or roller) 4. Oil filler port; from left to right they are (toothed or toothless) No teeth)): 1. Stopper 2. Plug pin (3) Inner ring (toothed or toothless) 4. Spacer or cage 5. Mounting hole (throttle hole or light hole).

Rotary bearings are widely used in actual industry and are called "machine joints". Their main applications are widely used in: cranes, rail cranes, port cranes, deck cranes, metallurgical cranes, container cranes, excavators, and filling machines. Such as CT machine standing wave therapy device, navigation, radar antenna tower, missile launcher, tank and robot, revolving restaurant, etc.

The slewing bearing model (Chinese standard) has the following parts:

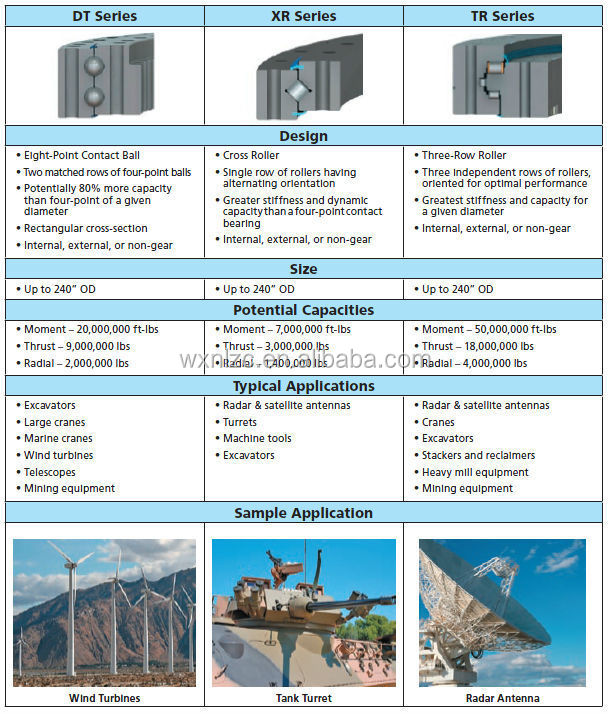

Single row four-point contact ball slew bearing series (01)

Double diameter ball slewing bearing series (02)

Single row crossed roller slew bearing series (11)

Three-row roller slew bearing series (13)

Single row four-point contact ball slew bearing (HS series)

Single row crossed roller slew bearing (HJ series)

Single row four-point contact ball slew bearing (QU, QW, QN series)

The slewing ring bearing model (INA standard) has the following parts:

Four-point contact slewing bearing series (VL)

Four-point contact slewing bearing series (VS)

Four-point contact slewing bearing series (V)

Single row crossed roller slew bearing series (XS)

Single row crossed roller slew bearing series (X)

There are two common types of noise in rotating bearings: dust and scratches. The solutions are as follows:

(1) Dust acoustic control method When the rotating body contains foreign matter such as dust, periodic vibration will occur. The so-called dust depends on the size and presence of vibration and noise. Dust sound control methods: Improve the cleaning method of slewing bearings/wheel hub bearings. Strictly clean the bearings, shafts, holes and all matching parts before installation; remove foreign matter in the lubricating oil; improve bearing seals; avoid using materials with inappropriate materials. Pure plastic cage or embedded foreign matter.

(2) Control method of scar sound When the rolling surface of the rotating bearing has cracks, indentations or rust, if any, periodic vibration and noise similar to rivets will occur. The period may be fixed, but most of it is related to the speed. The corresponding relationship between scars occurs continuously on the channel, there are scars on the ball, and the noise changes to a certain extent with the installation and lubrication conditions. Methods to control this type of noise include: do not knock when installing the bearing, prevent the bearing from tilting when installing the bearing into the bearing seat after assembling the bearing and the shaft; prevent the bearing from rusting in stock, and prevent shock and vibration during transportation; use high viscosity grease.

(3) Lubricant factors causing noise and their countermeasures Wrong selection and lack of lubricant, deterioration and hardening of lubricant will all lead to vibration and noise of slewing bearings/wheel hub bearings, and the noise has no certain rules. In this case, the only way is to select the appropriate lubricant, adjust its lubricant amount, extend the service life of the lubricant and provide a reasonable replacement cycle.

(4) Noise related to the main engine and its countermeasures. This kind of noise is not caused by simple bearings. Therefore, the cause should be found solely from the ineffectiveness of the bearing. Comprehensive attention should be paid when dealing with the main engine, and the performance of the main engine should be improved if necessary. The main narrative is in the common humming and frame resonance sounds of motors.

A. Motor hum and its countermeasures: The axial vibration of the motor shaft will cause a large amount of high-frequency noise and hum. Its frequency is the same as the axial vibration frequency and can be a constant change. The methods to prevent buzzing are the same as those to prevent axial vibration.

B. Bracket resonance sound and its countermeasures: The outer ring mass is the natural vibration caused by the axial bending vibration of the thrust bearing frame, which is called resonance noise. The method of increasing the preload force can improve the axial natural frequency and resonance conditions of the outer ring and reduce noise.

Methods to extend bearing life

1. Whether the installation is correct affects accuracy, life and performance. And add lubricating oil to the bearings after installation.

2. Strong impact is not allowed, such as hammer knocks and transfer roller pressure.

3. Use accurate installation tools and avoid using cloth and short fibers.

4. Lubricate the bearings with high-quality mineral oil to avoid rust, especially in summer

5. General inspection, such as ambient temperature, vibration and noise inspection

6. Keep bearings clean and free of dirt, dust, contaminants, and moisture.

7. Bearings should not be overcooled.

sample

Usually via EMS, DHL, UPS, TNT, Fedex. Anyway, whatever you like. Bulk orders: usually shipped by sea.

deliver goods

Within 7 days for samples or less than 100 pieces, 30-45 days for large quantities.

Warranty

The tracker's warranty is six months from the date of factory delivery, excluding accessories.

pay

It can be delivered via T/T, L/C.

Please inform us after payment so that we can arrange production as soon as possible.

-

Luoyang Hengchang Durable Mini Excavator Spare Parts Replacement Slewing Bearing Slewing Bearing for Volvo Ec55 In Stock

-

Forged RU85 crossed roller slewing bearing for heavy machinery

-

Perfect for slewing rings and slewing drives, FH slewing ring bearings

-

China manufacturer sell slew drive crawler crane slew drive bearing

-

Heavy Construction Excavator Mining Crane Slewing Ring Transmission Gearbox Slewing Ring for Solar Tracking System Industry

-

VE9 Solar System Slewing Drive Helical Gear Single Shaft Slewing Drive for Solar Panels, Vertical Slewing Drive

-

Ve9 12v Mini Slew Drives With Motor For Solar Tracking System

-

High Precision Roller Slewing Ring Excavator Bearing Slewing Ring

-

Lifting platform slewing bearing, excavator slewing bearing

-

LYJW Cheap Price Swing Circle CAT325 Excavator Parts Slewing Bearing Slewing Ring Bearings