Heavy Construction Excavator Mining Crane Slewing Ring Transmission Gearbox Slewing Ring for Solar Tracking System Industry

-

Supplier: CMN Industry Inc -

Region: California, China -

Contact: Mr Edison Gan -

Price: $23.00 / >=10 pieces -

Min. Order: 10 pieces

Product details

| Supply capacity: | 20000 sets per month | ratio: | 104:1 |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Applicable industries: | Building materials stores, manufacturing plants, machinery repair shops, farms, retail, construction, energy and mining, advertising agencies |

| Radial load: | 262 kN | Seal type: | - |

| Lifting moment: | 142.4 kNm | Axial load: | 1166 kN |

| Types of: | Slewing ring | Bounce: | ≤0.15° |

| Gear options: | Internal gear only | port: | Shanghai/Ningbo Port |

| brand: | cm | Holding torque: | 110 kNm |

| place of origin; place of origin: | Zhejiang, China | Packaging Details: | Carton + wooden box |

| feature: | cross roller |

Product Description

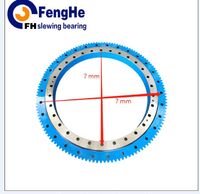

Slewing ring

The slewing bearings include single volleyball series, double volleyball series, three-row roller series, single-row cross roller series, light series, flange series and many other series. Our products range in size from 200mm-4,000mm and are available in standard and non-standard models.

Our products are mainly used in excavators, mobile cranes, tower cranes, and gradually widely used in construction machinery, light industry machinery, metallurgy and mining machinery, environmental protection machinery, petrochemical machinery, engineering vehicles, ship and port machinery and other fields.

Our products are mainly used in excavators, mobile cranes, tower cranes, and gradually widely used in construction machinery, light industry machinery, metallurgy and mining machinery, environmental protection machinery, petrochemical machinery, engineering vehicles, ship and port machinery and other fields.

rotary drive

The CMN semi-rotary drive is a gearbox designed to handle radial or axial loads with high rotational torque. Additionally, the slewing ring located in the center of the drive enables it to withstand high overhung or torque loads. The rotary drive is a derivative of the "worm" screw, and is widely used in many fields that require high strength and precision, such as construction machinery, manufacturing, and military equipment. The physics of slew drives make them a versatile solution for many applications. In operation, axial movements of the rotary drives, or movements about their axes, interact to generate radial torque. This is accomplished by engaging the grooves of the horizontal screw with the teeth of the vertical gear. During rotation, the axial movement of the worm gear transmits amplified torque to the radial gear. The number of flights on the horizontal screw and the number of interacting gears will determine the set speed ratio.

Processing Equipment

CNC vertical lathe (4 meters)

Hobbing machine (4 meters)

CNC High Speed Gear Cutting Machine

CNC milling machine (1.6 meters)

CNC gear cutting machine (1.6 meters)

CNC raceway grinder

heat treatment

Tempering furnace | CNC gear quenching | Raceway quenching | Tooth quenching |

application

The list of active applications for slew drives is extensive. Several types of industries require some form of slew drive to increase the efficiency of their operations. Mining, construction, metalworking and other applications requiring uncompromising strength and perfect precision use rotary technology to ensure safety and accuracy. Powerful equipment such as aerial lifts, rotary forklifts, truck mounted cranes, cable winders, fire trucks, hydraulic machinery and utility equipment all rely on the safety and strength of slew drives. Precision equipment such as military equipment, satellite dishes, solar trackers, printing presses and retractors benefit from the absolute precision provided by slew drives to function. To judge what kind of slew drive you need, you must know the configuration of the slew drive and the purpose of the equipment, each unit will have different specifications. When defining the type and capacity of a slew drive, the following variables are calculated:Gear ratio/accuracy/weight/output/overturning moment/torque/dynamic and static axial/radial dynamic

the wind

Ladle turntable

Ferris wheel

Crane

port crane

excavator

tower crane

filling machine

sea crane

marine crane

stacker reclaimer

Shield machine

VIEW MORE

You may like

-

Luoyang Hengchang Durable Mini Excavator Spare Parts Replacement Slewing Bearing Slewing Bearing for Volvo Ec55 In Stock

-

Crane slewing bearings & excavator slewing bearings slewing bearings

-

Forged RU85 crossed roller slewing bearing for heavy machinery

-

Perfect for slewing rings and slewing drives, FH slewing ring bearings

-

China manufacturer sell slew drive crawler crane slew drive bearing

-

VE9 Solar System Slewing Drive Helical Gear Single Shaft Slewing Drive for Solar Panels, Vertical Slewing Drive

-

Ve9 12v Mini Slew Drives With Motor For Solar Tracking System

-

High Precision Roller Slewing Ring Excavator Bearing Slewing Ring

-

Lifting platform slewing bearing, excavator slewing bearing

-

LYJW Cheap Price Swing Circle CAT325 Excavator Parts Slewing Bearing Slewing Ring Bearings

Related Search

crane construction and mining ltd

crane slewing bearing ring

crane slewing ring suppliers

truck crane slewing ring bearing

excavator slewing bearing for samsung

slewing bearing for hyundai excavator

heavy construction equipment for sale suppliers

slewing bearing for crane

slewing bearings for cranes

crane slew