PFB-D Automatic paper cup making machine

-

Supplier: Zhengzhou Perfect Co., Ltd. -

Region: Henan, China -

Contact: Ms Miranda Wang -

Price: $6900.00 /set -

Min. Order: 1 set

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Paper Cup Sizes: | 3-12 OZ or Customized sizes; |

| Product Type: | Paper Cup Machine; | Certification: | CE; |

| Dimension(L*W*H): | 2700 x 1400 x 1700 mm; | Suitable paper material: | 150gsm--380 gsm (single or double PE-coated paper); |

| Condition: | New; | Speed of paper cup making machine: | 50--65 pcs / minute; |

| Place of Origin: | Henan China (Mainland); | Voltage: | 380 / 220V or Customized; |

| Other name: | Automatic paper cup making machine; | Warranty: | 1 Year; |

| Power(W): | 6 KW; | After-sales Service Provided: | Video technical support,Online support; |

| Name: | Automatic paper cup making machine; | Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min; |

| Brand Name: | Fect; | Warranty: | ONE YEAR paper cup forming machine; |

| Supply Ability: | 35 Set/Sets per Month Automatic paper cup making machine; | Finished Products: | Single/ Double PE coated tea coffee paper cup; |

| Weight: | 2000 kg; | Packaging Detail: | Wooden case/ Automatic paper cup making machine; |

| Production Capacity: | 50--65 pcs / minute; | Application: | Automatic paper cup making machine; |

| Keyword: | Recycle Paper Cup Making Machine; | Port: | Ningbo/Shanghai; |

| Processing Type: | Paper cup forming machine; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Alibaba TradeAssurance; |

PFB-D Automatic paper cup making machine (vertical shaft and gear driving)

It runs a whole procedure of paper-feeding, cup-fan-wall sealing, oiling, bottom punching, heating, rolling, rimming, rounding and tripping. It is an ideal equipment for producing drinking cups, market cups, coffee cups, advertising cups , etc. It is widely used for hot drink and beverage.

If you need double pe coated paper cups or paper gram higher 250g/m2, we recommend you to use Ultrasonic paper cup machine. It can produce single pe coated paper cups and double pe coated paper cups.

♦Features♦

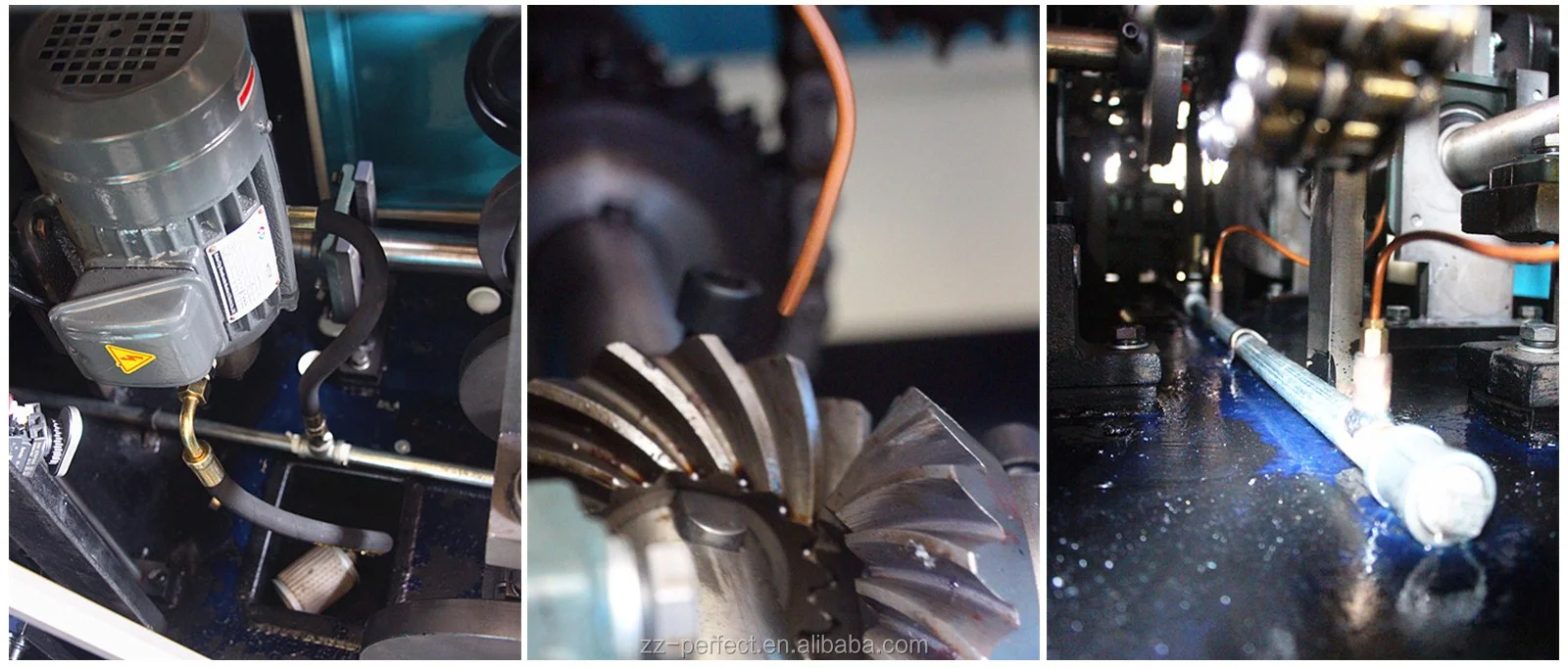

1. Use gear driving system instead of chain, more stable running and speed up.

2. Use automatic lubrication recycle system instead of oiling by hand to reduce the friction and wear between gears,improve the machine safety and reduce the cost of maintenance.

3. 125 type gear box,which is longer life and more accurate.Normally,100 type gear box is used.

4. 100 type speed reducer is used instead of 80 type.

5. New design knurling wheel is used to guarantee the even pressure and better bottom sealing.

6. Cup folding parts is controlled by three separate cams,and each folding clip can be adjusted by itself.

7.We use manipulator to transfer the cup body instead of falling itself by pipe,It is more stable and accurate under the fast running.

8. Change the Ø25 normal steel shaft to Ø30 imported steel shaft to be sttrengthened,longer life and more stable.

9. Organ type sucker is used for cup fan sucked to gaurantee powerful sucking and more successful.The life is much more longer than normal sucker.

♦Application♦

Automatic Paper tea coffee cup making machine, paper cup forming machine, paper cup molding machine

| Package detail | Seaworthy package |

| Package size | 2600*1350*1700mm |

| Gross weight | 2.2 T |

| Paper cup fan flex printing machine | 850 Paper cup punching machine |

|  |

| Automatic paper cup box creasing cutting machine | ML 750 Manual die cutting creasing machine |

|  |

1.Pre-Sales Service:

Our service team will glad to reply inquiry and consulting support in every way as soon as we can, we can support sample testing.

2. After sales Service

1.Spare parts guarantee for one year in machine arrival.

2.Send the technician for installation & training. Buyer bears the cost (round tickets,accommodation, and allowance of 70 USD per day)

3.Technical Support:

To ensure you get a top-notch experience, we can send our engineers to help you install properly, as well as provide local training for your employees.

Our sevice team will give you 24 hours support, and technical guidance by email, telephone, what's app and fax for regular maintainance and support.

Zhengzhou Perfect Co., Ltd. is a manufacturer of paper processing machinery with well-equipped testing facilities and strong technical force. Our main products including automatic roll die cutting and creasing machine, automatic paper carton erecting machine, automatic paper cup making machine and orhter paper food containers making machine. With a wide range, good quality, reasonable prices and stylish designs, our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

1.Q: How about your package?

A: Our machines are well wrapped by plastic film to be water proof first, then loading and fixing in a plywood case. If by FCL(full container loading) we might use the wooden pallet with plastic film wrapping, without plywood case.

2.Q:Can your machine be customized?

A: Your better improvement suggestions are highly appreciated. Almost all of our products can be customized, including the sizes, color, logo, package and so on.

3.Q :What's the OLD(order lead time)?

A: For our standard model machines is about 30days after receiving your deposit.

-

Paper Egg Tray Making Machine for Small BusinessesMachine for Fabricating Paper Egg Trays for Small Businesses

-

Factory supply low price fully automatic napkin machine napkin making machine price

-

Small Manufacturing Machine Automatic Toilet Paper Rewinder Complete Equipment

-

6kw High Speed Fully Automatic Disposable Paper Cup Machine Price India Marketing Copper Motor GSM Power Engine Pump Technology

-

Paper cup machine automatic paper cup machine paper cup machine price

-

Henan Fuyuan low-cost new egg tray machine small enterprise egg tray production line machine making egg tray

-

Fully automatic machine for making disposable coffee cups

-

High Quality Paper Cup Production Making Machine Price,paper Cup Making Machine

-

Automatic V Fold Facial Tissue Hand Towel Paper Making Processing Machine Production Line

-

Small Pocket Envelope Making Machine for envelope

Other Products

-

$13980.00 / set

$13980.00 / set -

$2000.00 / set

$2000.00 / set -

$20000.00 / set

$20000.00 / set