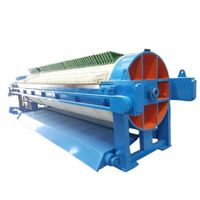

Rotary drum thickening belt filter press for sludge dewatering machines

-

Supplier: Jiangsu BOE Environmental Protection Technology Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Mandy Zhou -

Price: $21500.00 /set -

Min. Order: 1 set

| Material: | SS304/316; | Brand: | BOEEP; |

| Automatic Grade: | Automatic; | Warranty: | 1 YEAR; |

| Condition: | New; | Motor: | SEW/NORD/Customize; |

| Dimension(L*W*H): | 2600*1550*2540mm; | After-sales Service Provided: | Field installation, commissioning and training; |

| Voltage: | 380V; | Package Type: | usually wooden case, other packing methods also can be satisfied; |

| Weight: | 1100KG; | Power(W): | 1.11; |

| Capacity: | 5-10m3/h; | Place of Origin: | Jiangsu China (Mainland); |

| Certification: | CE, ISO, SGS; | Inlet concentration: | 1-5%; |

| Brand Name: | BOEEP; | Package Preview: | https://sc01.alicdn.com/kf/HTB1BZMWJ1uSBuNjSsplq6ze8pXaH.jpg_640x640.jpg; |

| Protection Level: | IP55 F; | Single gross weight: | 1,400 KG; |

| Mud cake moisture conten: | 75-85%; | Model: | ZDY1.0; |

| Electrical component: | Schneider/Omron/Customize; | Dried sludge: | 75-140kgds/h; |

| Single package size: | 290X190X300 cm; | Selling Units: | Single item; |

Product Introduction

ZDY Rotary drum belt filter press, it is mainly used for processing the sludge which is not concentrated in the thickening pool (such as A/O residual sludge), the sludge can be pre-dewatered by the rotary drum concentration, thus, this machine has two functions: concentraion and dewatering, its capacity is higher than the other dewatering devices which with simple filter pressing.

Structure & Working Principle

The main machine is composed of conditioning tank, concentrating shrink drum and belt filter, when the flocculated sludge feeds into the rotating thickening drum, the moving water flows from the rotary drum gap, washing device is set on the top of the rotary drum, which is to wash the drum. After thickening and dewatering, the sludge is distributed and feed onto the filter belt thoroughly. After pressed by the gravity dewatering zone, wedge compression zone, pre-pressing dewatering zone, low pressure dewatering zone, middle pressure dewatering zone, high pressure shear dewatering zone etc, the presser is put onto the sludge along the belt forwarding direction consistently, and the sludge cake will be output at the outlet port.

Adavantage

| 1. Adopting advanced technical design ideas, combined with years of design experience and integrated design, Belt Filter Press can run stably, no shock, no vibration and no noise. |

| 2. The surface has been treated as anticorrosion and painted with beautiful appearance. The structure is strong and durable. |

| 3. Belt position correcting system: automatic continuous detection, extend belt’s life. |

| 4. Press roller: SUS304, reinforced welding, machined by fine processing, enough strength. |

| 5. Air pressure control device: the filter cloth tensioned by cylinder runs in its scope stably without leakage, high security. |

| 6. Belt cloth: GKD, good durability and excellent corrosion resistance. |

| 7. Control panel: Omron or Schneider. PLC adopts Siemens, easy operation and maintenance. |

| 8. Sludge distributor: The thickened sludge shall be distributed evenly on the upper belt to ensure the equal squeezing pressure, improve dewatering efficiency & extend the life of belt cloth. |

| 9. Flocculator tank: Adopts different layout with different sludge inlet concentration, to mix the polymer and sludge thoroughly. |

Specification & Model Data

Product Details

Object Site

Click Here for Inquiry!

-

Alcove filter press factory well glass plate, fiberglass filter plate

-

Cement sludge dewatering circular filter press with plunger pump

-

Durable, high quality water filtration membrane filter press with cloth cleaning drip tray

-

Ceramic round chamber filter press with favorable price automatic customized filter press

-

Machine builder’s automatic membrane PP filter press for breweries

-

Refinery Edible Oil Biodiesel Pressure Leaf Filter

-

Solid-liquid separation filter press for wastewater treatment

-

High pressure reinforced polypropylene filter press PP filter plate

-

Multi-layer stainless steel plate filter media

-

Oil wine clay ceramic automatic filter press concave plate filter press chamber filter press

Other Products

-

$3500.00 / set

$3500.00 / set