Tablet pharmaceutical packaging, automatic stick packaging machine

-

Supplier: LODHA INTERNATIONAL LLP -

Region: Gujarat, India -

Contact: Mr. Dhananjay Lodha -

Price: $12500.00 / 1 - 4 units

$7500.00 / >=5 units -

Min. Order: 1 unit

Product details

| Showroom location: | Türkiye, Saudi Arabia, India, UAE | Voltage: | 220 volts |

| brand: | Loda | maximum. Aluminum foil width: | 230mm |

| Supply capacity: | 10 units per month | Main selling points: | competitive price |

| Video shipment inspection: | if | product name: | Tablet pharmaceutical packaging, automatic stick packaging machine |

| Yield: | Up to 150000 per hour | Core component warranty: | 1 year |

| Cutter Assembly: | Cam-operated cutter assembly with spring-loaded brake band. | Core components: | PLC, bearings, gearboxes, motors, gears |

| Health status: | new | Dimensions (L*W*H): | 1000 X 850 X 1850 mm |

| Packaging Details: | wooden packaging for export | usage: | Tablets and Capsules |

| port: | Navasheva | object: | Tablets Capsules and Lozenges |

| Gearbox: | 14:1 ratio, universal mount type (manufactured by "BONFIGLIOLI") | Optional features: | Non-Fill Detection (NFD) Systems |

| Marketing Type: | New Products 2020 | Weight (kg): | 350 |

| Applicable industries: | Manufacturing plants, pharmaceutical plants, health products, herbal medicines | BPA Unit (Batch Printing Unit): | Printing unit automatic cassette |

| Origin: | Gujarat, India | Certification: | ISO 9001:2015 and EU certification |

| Package preview: | After warranty service: | On-site maintenance and repair services | |

| strength: | 50 Hz | Warranty: | 2 years |

| Mechanical test report: | if | payment terms: | L/C, T/T |

Product Description

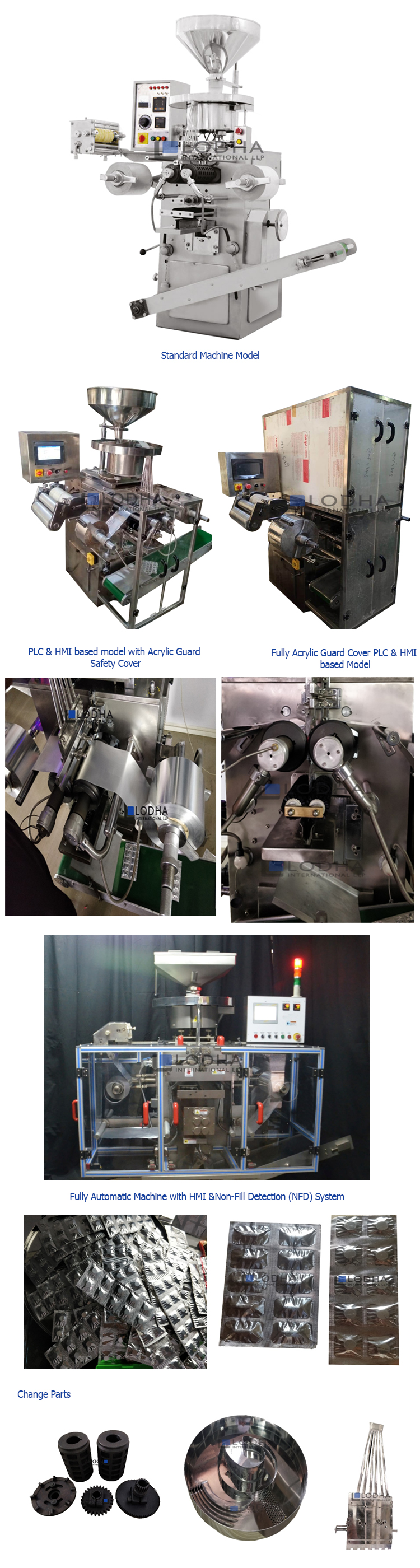

Tablet pharmaceutical packaging, automatic stick packaging machine

- Tablet Pharmaceutical Packaging, Automatic Stick Packaging Machine packs various products into easy-to-dispensing sticks, economically and quickly. Its capacity is between 500 units/min and 2500 units/min. It handles a wide variety of products such as coated and uncoated tablets of any size/shape, hard and soft gelatin capsules, confectionery products (eg lozenges, toffees, chewing gum) as well as electronic devices etc. Built on the basis of advanced technology to meet the requirements of the pharmaceutical packaging industry. Stick wrappers offer high speed and non-stop performance with low maintenance. They are ideal for high speed sealing of coated or uncoated tablets, capsules or lozenges of any shape or size in aluminum foil, polyethylene, cellophane or any other heat sealing material.

special function

- Automatic feeding, sealing, slitting and cutting are completed at the same time.

- Therefore, its high efficiency means that the cost of production is reduced due to the reduction of labor costs.

- Models from 2 rails to 10 rails,

- Minimum 40mm to maximum 310mm seal width.

- The conveyors of different sizes are taken down and the steel strips are transported to the inspection and packing station.

- Machines for different heat-sealed packaging laminates.

- Motors suitable for 415 V/ 380 V/ 3 PH/ 50 CS/ AC mains.

- All contact parts are SS316.

- Comply with cGMP.

- Changing parts can be easily replaced.

special accessories

- Synchronous batch encoding

- Print Registration Control

- Horizontal perforation

- vertical perforation

- zigzag cut

- Non-Fill Detection (NFD) Systems

- PLC

- multi-product feeding

- Use preformed rolls

- Security

- Notch for easy tearing

- Bulk Encoding Using Metal Types

- irregularly shaped pockets

- strip engraving

- Use of inkjet printing

- 5/7 tablet/capsule strip

flow chart:

- Vibrator: Conveys product to chute by supplying tablets.

- Chute: This device grips the various components and centers them so that they enter the seal roll.

- Sealing roller: Adopt precision temperature control device, the temperature of sealing roller is stable.

- Slitting: The number of columns and positions of slitting can be easily adjusted.

- Paint Brush: Pull the strip taut to ensure the seal and cut are perfect.

- Cutter: The number of cutting lines can be adjusted according to your needs

Specification

| Model | LI-ST 2 | LI-ST 4 | LI-ST 6 | LI-ST 8 | LI-ST 10 |

| Output - Tablets/hour | 15000 to 35000 | 35000 to 48000 | 48000 to 72000 | 60000 to 96000 | 75000 to 1,20,000 |

| Strip output/min. | 250 to 600 | 600-1200 | 1200-1800 | 1800-2500 | 2250 – 3125 |

| Film material | Aluminum paper/any heat sealing material | ||||

| Aluminum foil width (maximum) | 90 mm | 140 mm | 210 mm | 260mm | 310 mm |

| Foil roll diameter (maximum mm) | 400 | 400 | 300 | 300 | 300 |

| powder | 0.5 hp | 1 hp | 1 hp | 2 hp | 2 hp |

| heater | 1 kW | 1.5 kW | 2 kW | 3 kW | 3 kW |

| feeding arrangement | automatic vibration | ||||

| to cut | built-in arrangement | ||||

| Temperature Controller | Digital automatic temperature controller | ||||

| Cutting device | built-in arrangement | ||||

| in all respects | 1100 x 1050 x 1650mm | 1100 x 1050 x 1650mm | 1100 x 1150 x 1650mm | 1100 x 1150 x 1650 mm | 1200 x 1200 x 1800 mm |

| net weight | 380 kg. | 410 kg. | 450 kg. | 490 kg. | 550 kg. |

VIEW MORE

You may like

-

Leadtop Automatic Suppository Machine Suppository Shell Making Machine Vaginal Suppository Production Machine

-

Fully Automatic Suppository Machine/Suppository Filling and Sealing Equipment

-

Semi-automatic bullet suppository filling and sealing machine

-

Pharmaceutical non-PVC soft bag physiological saline intravenous injection filling and sealing production line

-

Suppository Mold Production Line Bottle Cylinder Power Packaging Technology Sales Video Computer Stand Liquid Weight

-

Blister capsule tablet defoaming machine for capsule and tablet recycling in China factory

-

Bottle filling production line capsule counting labeling machine line

-

SupLab-2 suppository filling and sealing machine

-

Pharmaceutical industry high-speed throttling machine production line

-

Automatic blister packaging machine with hard capsules DPB-140

Other Products

-

$2500.00 / unit

$2500.00 / unit

Related Search

Pharmaceutical Packaging Machines

automatic packaging machine cream biscuit

automatic vegetables fruit vacuum packaging machine

automatic cup packaging machine

automatic bread packaging machine manual

horizontal automatic packaging machine

semi automatic seam packaging machine

bakery automatic packaging machine

automatic thermoform vacuum packaging machine suppliers

automatic thermoforming packaging machine suppliers