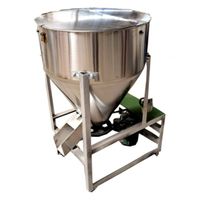

High Speed Vertical Plastic Mixer Plastic Weighing Mixer

-

Supplier: Jiangmen Xiecheng Machinery Co.,Ltd. -

Region: Guangdong, China -

Contact: Ms Amy Chau -

Price: $1900.00 /set -

Min. Order: 1 set

Product details

| Packaging Details: | Export wooden box packaging | Warranty: | 1 year |

| Supply capacity: | 300 sets per month | Power (watts): | 0.25KW |

| Maximum Noise Level: | <75dB | Additive hopper volume: | 32L |

| Main ingredient mixing range: | 5-100% | Origin: | Guangdong, China |

| port: | Jiangmen/Shenzhen/Guangzhou | Additive mixing range: | 0.5-10kg |

| Health status: | new | brand: | Synergy |

| Voltage: | 230V50Hz 1 phase | Applicable industries: | manufacturing plant |

| Weight (kg): | 155 kg | Production capacity: | 200 kg/h |

| Automatic level: | automatic | Dimensions (L*W*H): | custom made |

| Showroom location: | Vietnam, Brazil, Indonesia, Pakistan, India, Mexico, Russia, Thailand, Uzbekistan, Malaysia | Core component warranty: | 1 year |

| application: | Mixing of plastic raw materials | Core components: | PLC, motor |

| Mobile Standard (H1*H2*W*D): | 800*850*780*610mm | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Mechanical test report: | if | Main hopper volume: | 32L |

| Minxing barrel volume: | 20L | Base (height*width*depth*B*A*C): | 200*313*323*180*150*13mm |

| Video shipment inspection: | if |

Product Description

gravity mixer

Xiecheng weighing mixer is suitable for injection molding, extrusion and blow molding production where more than one material is mixed in different proportions.

product specification

Model | XGB-100 | XGB-200 | XGB-400 | XGB-600 |

Number of group numbers | 4 | 4 | 4 | 4 |

Stirring capacity(kg/hr) | 100 | 200 | 400 | 600 |

Batch weight (kg) | 3 | 3.5 | 8 | 10 |

Main ingredient mixing range (%) | 5~100 | 5~100 | 5~100 | 5~100 |

Additive mixing range (%) | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 |

Main hopper volume(L) | 25 | 32 | 45 | 70 |

Hopper volume (L) | 8 | 12 | 15 | 18 |

Mixing tank volume (L) | 10 | 10 | 18 | 25 |

Power (V/Hz) | 1Φ230/50 | 1Φ230/50 | 3Φ400/50 | 3Φ400/50 |

Total power(kw) | 0.12 | 0.25 | 0.55 | 0.55 |

Compressed air (kgf/cm2) | 6~8 | 6~8 | 6~8 | 6~8 |

maximum. Noise level (decibels) | <75 | <75 | <75 | <75 |

Well) | 1725 | 1745 | 1905 | 1905 |

Width (mm) | 925 | 825 | 940 | 940 |

Diameter (mm) | 700 | 750 | 910 | 910 |

Base (mm) (HxWxDxBxAxC) | 200*375*275* 150*150-Φ100 | 280*535*415* 150*150-Φ100 | 280*535*415* 150*150-Φ100 | 280*535*415* 150*150-Φ100 |

Mobile tripod(mm) (H1xH2xWxD) | 660*675*560 | 660*675*560 | 800*850*780*610 | 800*850*780*610 |

net weight/kg) (machine installation) | Post-90s | 130 | 140 | 180 |

net weight/kg) (floor installation) | 110 | 155 | 165 | 230 |

If you need more sizes, please contact us for details

Products real shot

Product Details

01 PLC controller

▪ usePLC controller, higher control accuracy, more stable, and easy maintenance; ▪ The standard model can handle 4 components, and the model with more than 6 components can be customized; ▪ Color graphic display, touch screen operation, multiple language options; ▪ With more than 100 Formula saving function for formula; ▪ Hierarchical security password control and alarm history recording function; ▪ USB2.0 interface, used to save formula data to flash disk, convenient for quality management.

02Gravity sensor

▪ Using advanced control algorithm, self-optimization,Automatic adjustment compensation and anti-vibration functionTo ensure the best batching accuracy. ▪ High precision: proportional error can be controlled within0.3% -0.5%.

03 metering valve

adoptionSide Pull Metering Valve, and the material ratio is less than 5%.Screw Metering ValveAfter use, the blanking accuracy is more accurate, the maintenance is simple, and the replacement is convenient.

04 paddle

All raw material contact parts are made of stainless steel to prevent material contamination.

05 Siemens Electric

It adopts the world-renowned brand Siemens electrical components with stable performance.

work rules

The machine starts to work, the metering valve is opened, and the material is discharged according to the set value. If the controller detects that the output volume reaches the set value, the metering valve is closed. If the output volume remains within the allowable error range, the machine will discharge the next material. When all material has been added, the scale valve opens, releasing the material into the mixing tank. The blender motor starts blending. The mixing time can be set by the controller. The mixture will be drained into the storage tank and ready for injection.

VIEW MORE

You may like

-

Plastic sheet extrusion mixer

-

PP PE ABS CE Industrial mixer Vertical mixer with plastic granules

-

Factory direct sales high quality plastic vertical mixer

-

Best Price Vertical Plastic Color Mixer/Mixer

-

LESINTOR new PET PE ABS ribbon powder mixer mixer dry powder coloring machine

-

Vertical plastic mixer 100 kg

-

Easy Clean Plastic Color Mixer Plastic Color Mixer

-

volumetric plastic mixer with color doser for extruder

-

Stainless steel vertical flat mouth mixer vertical spiral powder seasoning mixer

-

Plastic extruder single screw volumetric feeder

Other Products

-

$900.00 / set

$900.00 / set -

$620.00 - $680.00 / set

$620.00 - $680.00 / set -

$900.00 - $980.00 / set

$900.00 - $980.00 / set -

$700.00 / set

$700.00 / set -

$1600.00 / set

$1600.00 / set -

$1600.00 / set

$1600.00 / set -

$7700.00 / piece

$7700.00 / piece -

$450.00 / set

$450.00 / set -

$1600.00 / set

$1600.00 / set -

$499.00 / set

$499.00 / set

Related Search

vertical plastic resin mixer

high speed plastic bag continuous sealer

plastics high speed crusher

high speed hole punching machine for plastic

high quality goniometer plastic ruler

vertical plastic molding injection machines

vertical plastic injection machines

injection machine vertical plastic

high quality pvc plastic trowel suppliers

high speed weighing machine conveyor