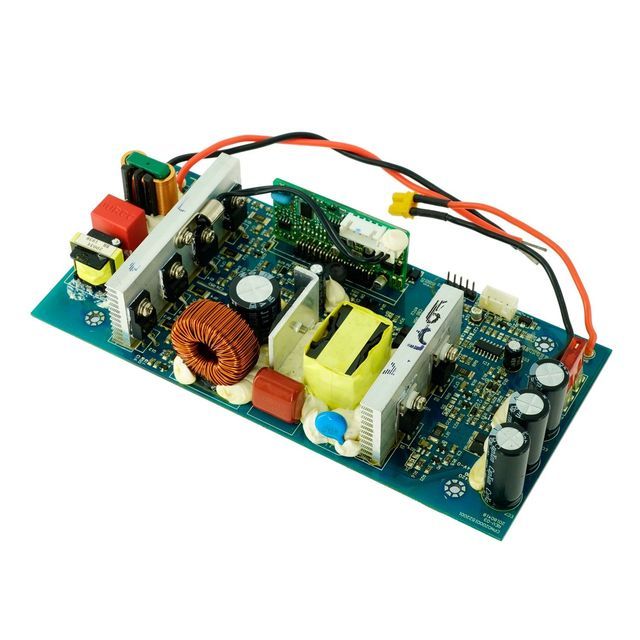

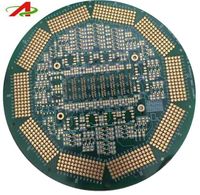

Factory Wholesale Balancer Smart Switch PCBA OEM Service PCB Board Multilayer PCBA PCB Manufacturer PCB Service

-

Supplier: Shenzhen Jingxin Electronic Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms JingXin PCBA -

Price: $4.25 / 2 - 99 pieces

$3.88 / 100 - 999 pieces

$2.55 / 1000 - 9999 pieces

$0.88 / >=10000 pieces -

Min. Order: 2 pieces

Product details

| Package preview: | Plate thickness: | 0.2mm-7.0mm, 1.6mm | |

| Supply capacity: | 180,000 PCB assembly prototypes per month | Testing service: | AOI X-Ray function test |

| Board Dimensions: | 550*550mm | Material: | FR4/CEM-1/CEM-3/FR1/Aluminum |

| Substrate: | FR-4 | Copper thickness: | 5 oz |

| Serve: | One-stop turnkey | Minute Hole Size: | 0.2mm |

| Packaging Details: | Customized, anti-static bag/vacuum packing+bubble bag, | port: | Shenzhen/Hong Kong |

| layer: | 1-58 floors | Surface treatment: | HASL\OSP\Immersion Gold, HSAL/GOLD/OSP |

| Product Category: | Custom HDI PCBAs | Certificate: | ISO9001/Iso14001/CE/ROHS |

| Solder mask color: | Blue.Green.Red.Black.White etc. | model: | PCBA-415321 |

| brand: | Jinxin PCBA | application: | Electronic Equipment/Household Appliances |

| payment terms: | Western Union, L/C, D/P, D/A, T/T, MoneyGram, Paypal | Minute line width: | 0.075mm |

| Minute line spacing: | 0.075mm | type: | thick copper plate |

| Origin: | Guangdong, China |

company information

Product Description

| semester | PCBA board manufacturing detailed specification |

| layer | 1-30 floors |

| Material | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, FR-1, FR-2, Aluminum |

| plate thickness | 0.4mm-4mm |

| The largest finished board edge | 1020mm*1000mm |

| Minimum drilling size | 0.25mm |

| Minimum Line Width | 0.10 mm (4 million) |

| Minimum line spacing | 0.10 mm (4 million) |

| Surface Finish/Treatment | HASL/HASL lead free, chemical tin, chemical gold, immersion gold immersion silver/gold, Osp, gold plating |

| copper thickness | 1/2 oz 1 oz 2 oz 3 oz |

| Solder mask color | Green/Black/White/Red/Blue/Yellow |

| inner packaging | Vacuum packing, plastic bag |

| outer packaging | Standard carton packaging |

| Hole Tolerance | PTH: ±0.076, NTPH: ±0.05 |

| Certificate | ISO9001,ISO14001,ROHS,CQC |

| Profile punching | Routing, V-CUT, Bevel |

| Assembly service | Provide OEM service for various printed circuit board assembly |

|

skills requirement |

Professional surface mount and through-hole soldering technology |

| 1206, 0805, 0603 and other components of various sizes SMT technology | |

| ICT (In Circuit Test), FCT (Functional Circuit Test) technology | |

| PCBA assembly with CE, FCC, Rohs certification | |

| Nitrogen reflow soldering technology for SMT | |

| High standard SMT&Solder assembly line | |

| High-density interconnection board mounting technology capabilities |

| Quotation & Production Request | Gerber file or PCBA file for bare PCBA board fabrication |

| Bom(Bill of Material) for Assembly, PNP(Pick and Place file) and Components Position also need to be assembled | |

| To reduce quoting time, please provide us with the full part number of each component, the quantity per board, and the order quantity. | |

| Test guidelines & functional test methods to ensure quality with almost 0% scrap rate |

| OEM/ODM/EMS service | PCBA, PCBAA assembly: SMT & PTH & BGA |

| PCBA and case design | |

| Component procurement | |

| rapid prototyping | |

| injection molding | |

| Sheet Metal Stamping | |

| final assembly | |

| Test: AOI, In-Circuit Test (ICT), Functional Test (FCT) | |

| Material import and product export customs clearance |

| Other PCBA assembly equipment | Mounter: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4 |

| Reflow Oven: FolunGwin FL-RX860 | |

| Wave soldering machine: FolunGwin ADS300 | |

| Automated Optical Inspection (AOI): Aleader ALD-H-350B, X-RAY Inspection Service | |

| Fully automatic SMT stencil printing machine: FolunGwin Win-5 |

Main PCBA application

Bare PCBA Manufacturing

Smart home equipment PCBA

Telecom PCBA Assembly

BLE & WIFI module PCBA

IoT smart sensor PCBA assembly

Home appliance PCBA assembly

Industrial control PCBA assembly

Medical device PCBA assembly

Safety equipment-PCBA

LoRa product assembly

Payment and Energy Products PCBA

Wearable Device Assembly

Jingxin Electronics PCBA assembly view

1) Professional surface mount and through-hole soldering technology

2) SMT technology for components of various sizes such as 1206, 0805, 0603

3) ICT (In Circuit Test), FCT (Functional Circuit Test) technology.

4) PCBA assembly with CE, FCC, Rohs certification

5) SMT nitrogen reflow technology.

6) High standard SMT&solder assembly line

7) High-density interconnection board mounting technology capabilities.

2) SMT technology for components of various sizes such as 1206, 0805, 0603

3) ICT (In Circuit Test), FCT (Functional Circuit Test) technology.

4) PCBA assembly with CE, FCC, Rohs certification

5) SMT nitrogen reflow technology.

6) High standard SMT&solder assembly line

7) High-density interconnection board mounting technology capabilities.

our service

rapid prototyping

Fast turnaround around 24 hours Electronic PCB Prototyping Rapid Prototyping Turnkey Electronic PCB Assembly within 7 days High-End Manufacturers: Rigid, Flex,

Rigid-Flex, HDI, Metal Core, 10-40 layers etc. Manufacturing on demand

Rigid-Flex, HDI, Metal Core, 10-40 layers etc. Manufacturing on demand

Strong Supply Chain Management

Includes a wide range of qualified dealers and a large selection of stocks. Components are ready to ship or assemble

100,000+ parts inventory assemblies

2000m² component warehouse

800+ qualified suppliers

50+ expert procurement team

20+ seconds instant results

7,000,000+ parts real-time inventory and prices

Prototyping (quick turns available)

Standard electronic printed circuit board 1-10 layers FR4 · Original build time 72h + shipping time 48h · Urgentbuild time 48h + shipping time 48h · Extra

Urgent build time 24 hours + shipping time 24 hours Advanced Electronics PCB (10-40 layers, HDI, Military, etc.) Original build time 10-12 days +

Delivery time 48h

Urgent build time 24 hours + shipping time 24 hours Advanced Electronics PCB (10-40 layers, HDI, Military, etc.) Original build time 10-12 days +

Delivery time 48h

Mass production, small batch & mediumVolume · Competitive Price · Smallest. Board thickness 0.2mm · Min. trace/spacing 3.5 million ·

quick turn available

Full Service Turnkey Electronics PCB Assembly Solutions Electronics PCB Fabrication, Component Sourcing and In-House Assembly, Total Project Management

usable

quick turn available

Full Service Turnkey Electronics PCB Assembly Solutions Electronics PCB Fabrication, Component Sourcing and In-House Assembly, Total Project Management

usable

Packaging and Shipping

packaging and shipping

Our company not only strives to provide customers with good products, but also pays attention to providing complete and safe packaging. Here we have prepared some personalization for all orders.

normal packaging:

PCB: Carton vacuum packing

PCBA: ESD package with carton

Shipping:1. Confirm your shipping address is correct before shipping 2. Process order in time after payment verification 3. Professional packaging. Don't worry about the goods being damaged. 4. Service transit time varies by carrier, especially holidays may vary.

VIEW MORE

You may like

-

Smart BMS circuit board 3S 4S 6S 3-20S, 12V 24V 36V 48V 6-80Ah suitable for lithium iron/ternary battery customization

-

Hot sale OEM PCB factory 1oz,2oz,3oz,4oz,5oz,6oz rigid/flex thick copper PCB

-

Jinhua OEM custom black dipped tin extra long pcb FR4 3L thick copper circuit board manufacturer

-

Custom Copper Pcb Other Pcb & Pcba Pcb Assembly Manufacturer Pcba Assembly Manufacturer

-

OV5648 OV5640 with 5MP omnivision cmos sensor DVP IR-CUT camera module with flex cable

-

RoHS Compliant FR4 94v0 BasChip IC Decode pcb design electronic pcb reverse engineering service Circuit Board Manufacturer

-

China PCB manufacturer provides one-stop service electronic printed circuit board/pcb assembly

-

smt batch custom solar LED street light PCBA

-

Electronic product double-sided PCB assembly

-

13 years high frequency OEM experience and manufacturing design of android mobile pcb board to other pcb

Other Products

-

$0.88 - $4.25 / piece

$0.88 - $4.25 / piece -

$1.01 - $4.25 / piece

$1.01 - $4.25 / piece -

$0.88 - $4.25 / piece

$0.88 - $4.25 / piece -

$1.01 - $4.25 / piece

$1.01 - $4.25 / piece