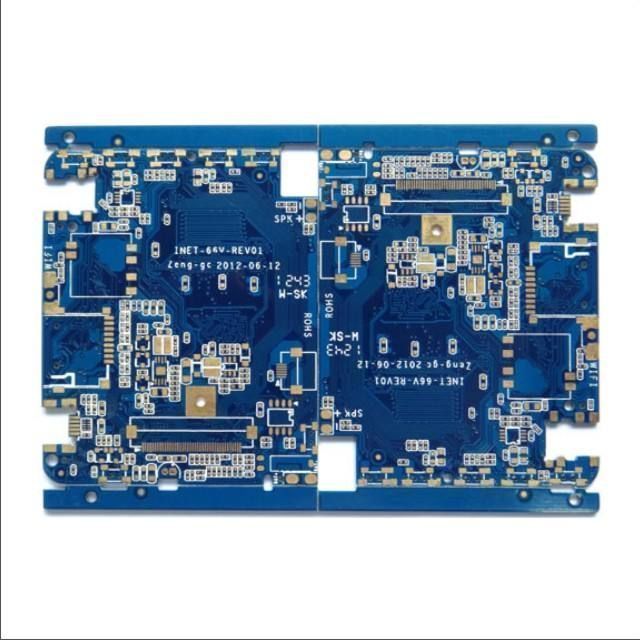

Electronic product double-sided PCB assembly

-

Supplier: Shenzhen City Yueda Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Christine Qiu -

Price: $0.10 /piece -

Min. Order: 1 piece

Product details

| Layers: | 1-32 liters | port: | Shenzhen |

| Supply capacity: | 500,000 pieces per month | Packaging Preview: | |

| color: | blue green black red | minute. Line spacing: | 3000000 |

| Plate thickness: | 1.6mm | product name: | Custom Double Sided PCB |

| application: | Large, medium and small projects | PCBA service: | SMT DIP Assembly |

| minute. Line width: | 3000000 | Minimum order quantity: | 1 |

| Surface treatment: | Spray tin, nickel | model: | YDM20 |

| Packaging Details: | Bubble bag inside, international standard carton outside | Serve: | EMS, ODM, OEM |

| minute. Hole size: | 6mil, 4mil-laser drilling | Copper Thickness: | 0.5oz - 6.0oz |

| payment terms: | letter of credit, wire transfer | type: | Electronic board, heavy copper pcb |

| size: | Maximum 600*1200MM | pack: | vacuum packaging |

| Substrate: | FR-4 Glass Epoxy | brand: | Yueda |

| place of origin; place of origin: | Guangdong, China |

Product Description

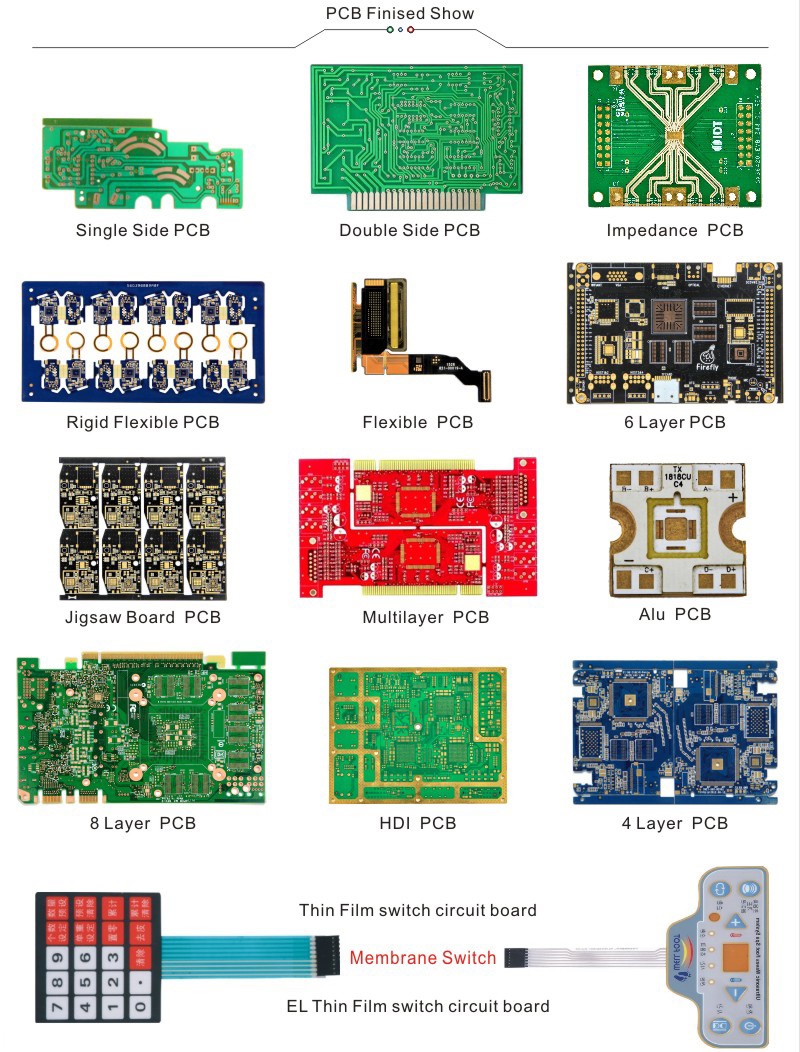

PCB manufacturing

PCB manufacturing

| Do not. | thing | Specification |

| PCB Manufacturing Capability | ||

| 1 | PCB layer | 1 to 32 floors |

| 2 | PCB board material type | CEM-1, FR4, High-TG FR4, ALU, CEM-3, Rogers, HDI, etc. |

| 3 | biggest size | 600×1200mm |

| 4 | Minimum line width | 0.1mm |

| 5 | Minimum spacing | 0.1mm |

| 6 | Dimensional tolerance | ±0.1mm |

| 7 | Minimum aperture | 0.2mm |

| 8 | PCB thickness coverage | 0.2 to 6.0 mm |

| 9 | Minimum copper thickness in hole | 0.02mm |

| 10 | DK thickness | 0.08 to 6.0mm |

| 11 | NPTH Dimensional Tolerance | ±0.025mm |

| 12 | PTH Dimensional Tolerance | ±0.025mm |

| 13 | Dimensional tolerance | ±0.1mm |

| 14 | Hole tolerance | 0.075mm |

| 15 | Laser drill size | 0.1mm |

| 16 | minimal gas mask | 0.01mm |

| 17 | Solder mask separation ring minimum size | 0.05mm |

| 18 | Maximum board twist and wrap | ≤1% |

| 19 | Finished Aperture | 0.2 to 6.0 mm |

| 20 | flame retardancy | 94V-0 |

| twenty one | Impedance Control Tolerance | ±5% |

| twenty two | Outer copper thickness | 8.75 to 175 microns |

| twenty three | Inner layer copper thickness | 17.5 to 175 microns |

| twenty four | Solder mask type | blue, green, black, yellow, red, white |

| 25 | surface treatment | ENIG, gold plating, immersion silver, immersion tin, etc. |

| 26 | Certificate | ISO9001, ISO14001, ISO14969 |

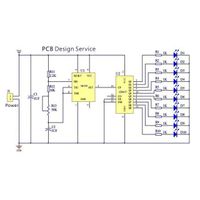

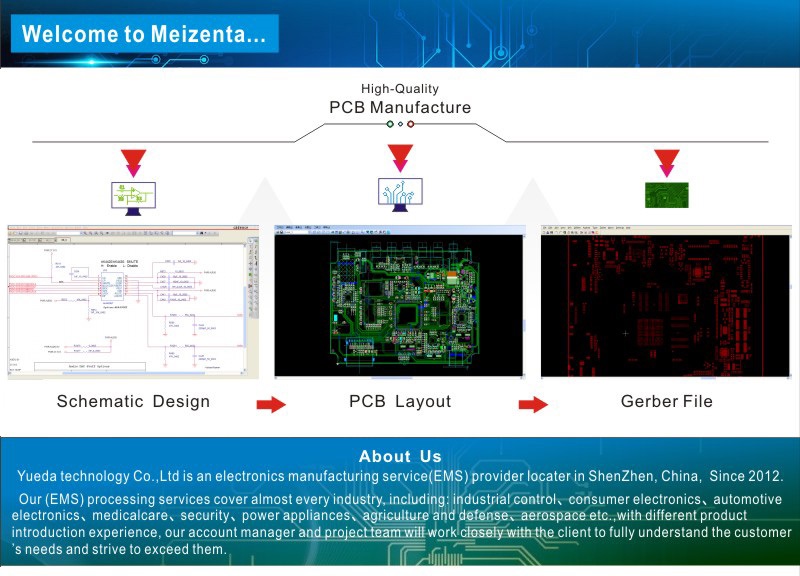

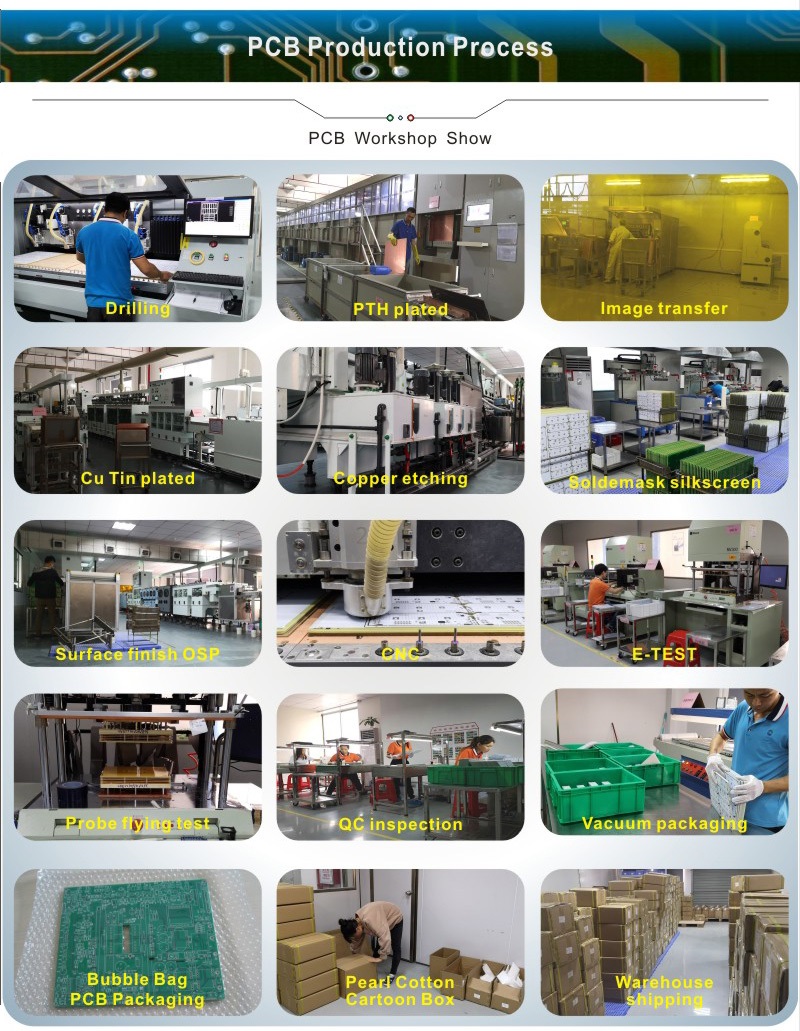

Production Process

our service

Capabilities and scope of services:

♦PCB circuit layout and production

♦Plastic and metal shell design service

♦Product custom packaging design

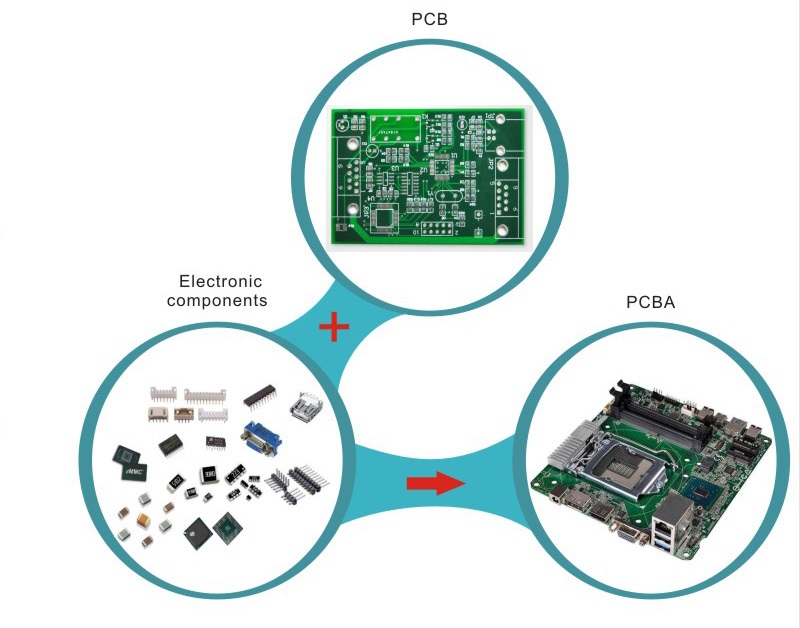

♦SMT/SMD parts assembly and dip through hole soldering (PCBA)

♦IC programming software (pre-programming), PCBA function test and verification

♦ Complete product assembly (including plastic, metal case, PCBA motherboard, cables, switches and other components, etc.)

♦ROHS environmental protection material supply

♦Logistics arrangement to import and export goods from China

Packaging and Shipping

VIEW MORE

You may like

-

Smart BMS circuit board 3S 4S 6S 3-20S, 12V 24V 36V 48V 6-80Ah suitable for lithium iron/ternary battery customization

-

Hot sale OEM PCB factory 1oz,2oz,3oz,4oz,5oz,6oz rigid/flex thick copper PCB

-

Jinhua OEM custom black dipped tin extra long pcb FR4 3L thick copper circuit board manufacturer

-

Factory Wholesale Balancer Smart Switch PCBA OEM Service PCB Board Multilayer PCBA PCB Manufacturer PCB Service

-

Custom Copper Pcb Other Pcb & Pcba Pcb Assembly Manufacturer Pcba Assembly Manufacturer

-

OV5648 OV5640 with 5MP omnivision cmos sensor DVP IR-CUT camera module with flex cable

-

RoHS Compliant FR4 94v0 BasChip IC Decode pcb design electronic pcb reverse engineering service Circuit Board Manufacturer

-

China PCB manufacturer provides one-stop service electronic printed circuit board/pcb assembly

-

smt batch custom solar LED street light PCBA

-

13 years high frequency OEM experience and manufacturing design of android mobile pcb board to other pcb

Other Products

-

$0.10 - $0.35 / piece

$0.10 - $0.35 / piece -

$0.10 / piece

$0.10 / piece