Vane demister stainless steel 304 in cooling tower

-

Supplier: Raoyang County Ruihang Wire Mesh Products Co., Ltd. -

Region: Hebei, China -

Contact: Mr Jack li -

Price: $300.00 / 1 - 49 sets

$60.00 / >=50 sets -

Min. Order: 1 set

Product details

| Core components: | knitted mesh | length: | Customer requirements, 100-3000mm |

| MOQ: | 1 set | Warranty: | 6 months |

| Supply capacity: | 50 sets per day | Packaging Details: | Braided Wire Gasket Demist Mat Export Standard Packaging: Wooden Box |

| Braid style: | Single-strand braid, multi-strand braid, multi-strand fiber braid | Marketing Type: | 2019 Hot Products |

| Filter class: | 99.9% | application: | industry filter |

| width: | Custom size, 100-4000mm | Hole shape: | round square diamonds as your request |

| type: | filter element | Health status: | new |

| port: | Tianjin Xingang | Video shipment inspection: | if |

| Mechanical test report: | if | payment terms: | Western Union, T/T, Paypal |

| feature: | Heat-resistant and corrosion-resistant | thickness: | 150mm-600mm |

| product name: | Knitted Mesh Demister Mat | Showroom location: | not any |

| Package: | wooden box | use: | liquid filter |

| Wire diameter: | 0.08mm-0.30mm | Filter class: | 99.9% |

| Origin: | Hebei china | shape: | round rectangle or customized |

| Core component warranty: | 3 months | Package preview: | |

| Weight (kg): | 7.5 | Material: | stainless steel as your request |

| usage: | liquid filter | brand: | Swiss Air |

| Applicable industries: | Chemical Petroleum Metallurgy |

Product Description

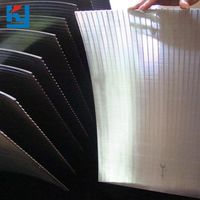

Vane demister stainless steel 304 in cooling tower

Vane type mist eliminator, also known as herringbone type mist eliminator, vane type mist eliminator, is a widely used and economical

Industrial equipment for the separation of gases and liquids. Vane plate mist eliminator supply multi-channel large contact

chemical, petroleum, pharmaceutical,

Coal gas, environmental protection and other fields.

Industrial equipment for the separation of gases and liquids. Vane plate mist eliminator supply multi-channel large contact

chemical, petroleum, pharmaceutical,

Coal gas, environmental protection and other fields.

Specifications

Material: metal or plastic.

Board span: 1/2", 3/4", 3/8", 1", 1-1/2", 2", etc.

Wave Height: 5" or 8".

Plate thickness: 0.46 mm and other customized specifications.

Section Depth: 1/2" to 3/8".

Section Depth: 1/2" to 3/8".

application

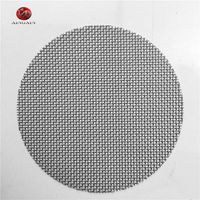

Knitted mesh demister mats can be installed in different packed towers and equipment for different media and gases

Filter and separate.

Filter and separate.

separation tower.

purification tower.

scrubber.

other specific towers.

distillation tower.

refinery tower.

Desulfurization tower.

feature

Excellent resistance to particle clogging.

The multi-channel structure provides large contact area and high separation performance.

Capacity is 30% to 100% higher than wire mesh demister pads.

High temperature resistance and excellent chemical stability.

Capacity is 30% to 100% higher than wire mesh demister pads.

High temperature resistance and excellent chemical stability.

Good self-cleaning performance and low maintenance cost.

Working principle of vane plate mist eliminator

The working principle of the vane plate mist eliminator and

Knitted mesh defogger pad. When the gas carries particles or droplets

The mist rises, passes the vine path, and the air changes

up direction. The momentum of the droplet forces it to hit

blades and coalesce into larger droplets that are eventually expelled from the blades when the force of gravity is greater than the lift force of the gas

and the surface tension of the liquid. Multi-channel structure improves separation and filtration efficiency many times

filter and block.

Knitted mesh defogger pad. When the gas carries particles or droplets

The mist rises, passes the vine path, and the air changes

up direction. The momentum of the droplet forces it to hit

blades and coalesce into larger droplets that are eventually expelled from the blades when the force of gravity is greater than the lift force of the gas

and the surface tension of the liquid. Multi-channel structure improves separation and filtration efficiency many times

filter and block.

Material and shape of vane plate demister

Metal vane plate demister

Plastic vane plate mist eliminator

the whole frame

.

separate structure

airflow configuration

When installed, the airflow configuration of the vane plate demister is vertical or horizontal airflow through the herringbone demister. No matter from which direction, a high separation efficiency can be maintained. In some specific applications, the inclined arrangement can facilitate the drainage of liquid or particles. Typically, the capacity of horizontal airflow is 30% greater than that of vertical airflow.

horizontal airflow

vertical airflow

VIEW MORE

You may like

-

Low price nylon filter cloth 5 10 20 30 40 50 60 70 80 90 100 200 300 400 500 600 700 800 microns

-

Personalized stainless steel coffee brewing filter

-

Hot Sale Durable Stainless Steel Wire Mesh Wedge Wire Curved Screen Mesh

-

SS 304 10 20 30 40 50 60 80 100 mesh stainless steel ring wire mesh filter disc

-

5 10 25 30 40 50 60 70 80 90 100 150 200 250 300 400 500 600 700 800 micron nylon filter

-

100 300 400 800 micron stainless steel wheat basket for home brewing

-

Manufacturer Custom Metal Filter Basket 304 316 Stainless Steel Perforated Filter Tube

-

Medical high flow sintered porous UHMWPE PE filter element

-

40 60 100 200 mesh stainless steel 304 316 316L filter mesh cap

-

HENGKO 1 2 5 10 micron SS 304 316L Porous Metal Sintered Stainless Steel High Precision Sintered Very Hard Filter

Related Search

distributors of stainless steel bolts in us

stainless steel 304 thimbles

stainless steel 304 lifting eye bolt

emi shielding stainless steel 304

stainless steel 304 u shape bolts

stainless steel 304 air shower

stainless steel 304 electrical conduit

stainless steel wire 304

tower bolt stainless steel

jisco stainless steel tp 321 coil in china