HENGKO 1 2 5 10 micron SS 304 316L Porous Metal Sintered Stainless Steel High Precision Sintered Very Hard Filter

-

Supplier: Hengko Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Zron Xie -

Price: $2.00 / >=5 pieces -

Min. Order: 5 pieces

Product details

| usage: | liquid filter | Advantage: | Uniform porosity and uniform particle distribution |

| Packaging Preview: | Warranty: | 3 months | |

| special service: | OEM ODM | Marketing Type: | normal product |

| technology: | powder sintering | Health status: | new |

| Filter level: | 40% | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,paypal |

| Pore Size: | 0.2um, 0.5um, 2um, 5um, 10um, 15um, 20um, 40um, 60um, 90um, 100um | product name: | SS 304 316L Sintered Stainless Steel Composite Wire Mesh Filter |

| length: | 500 | Supply capacity: | 5,000,000 sintered filter plates per month |

| Hole shape: | round | port: | Shenzhen Port |

| Applicable industries: | Manufacturing Plants, Food and Beverage Plants, Construction Works, Food and Beverage Stores | Mechanical test report: | if |

| feature: | beautiful appearance | place of origin; place of origin: | Guangdong, China |

| Material: | Stainless steel 316L, SUS 304, 316 stainless steel | thickness: | 1.5 |

| greatest pressure: | 5MPa | application: | Filtration of water, oil, gas and industrial systems |

| Core Components Warranty: | 3 months | Local service location: | not any |

| structure: | Tubes, trays, cups, trays, casings, cartridges | type: | filter element |

| brand: | Hengke | Showroom location: | not any |

| Core components: | Sintered stainless steel, SS filter | Packaging Details: | Standard export packing in carton or wooden case, or according to your specific requirements. |

| width: | 500 | After Warranty Service: | Online support |

| Video external inspection: | if |

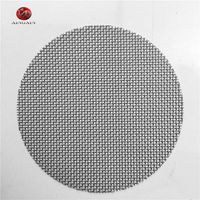

HENGKO 1 2 5 10 micron SS 304 316L sintered stainless steel porous metal high difficulty sintered high precision filter

Product Description

HengkeFilters are manufactured in a variety of materials, sizes and fittings so they can be easily specified according to the characteristics and configurations required by the customer. We can incorporate custom features or create completely original filter designs to meet special needs. Our filters are also available in a variety of different alloys, each with their own specific benefits and application purposes. Due to their heat, corrosion and physical abrasion resistance, they are a popular choice for many industrial filtration applications.

Typical uses include:

| 1. In the production process of chemical raw materials, impurity removal filtration, decarbonization filtration and fine filtration of materials. |

| 2. Ultrafiltration, RO, EDI safety filtration of water treatment. |

| 3. Clarification and filtration of beverages, fruit juice, liquor, beer, vegetable oil, mineral water, soy sauce and vinegar in food and beverage. |

| 4. Decarbonization filtration and precision filtration of liquid products, liquid raw materials, and pharmaceutical intermediates in the chemical industry, filtration and recovery of ultra-fine crystals and catalysts, precision filtration after resin adsorption, impurity removal and filtration of heat transfer oil and materials, catalytic gas purification, etc. . |

| 5. Reverse osmosis safety filtration in fields such as oil field reinjection water filtration. |

| 6. High temperature decarburization and dewhitening filtration in the dye industry. |

| 7. Steam, compressed air and catalyst filtration for gas purification. |

| 8. Purification and current limiting of pneumatic components, lubricating oil, fuel oil, hydraulic pressure, compressed air degreasing and purification, crude oil degreasing filtration, nitrogen and hydrogen filtration, pure oxygen filtration, bubble generator, floating bed gas distribution and other media. |

Want to learn more or want to get a quote?

clickchat nowThe button in the upper right corner contact our salesperson.

Product display

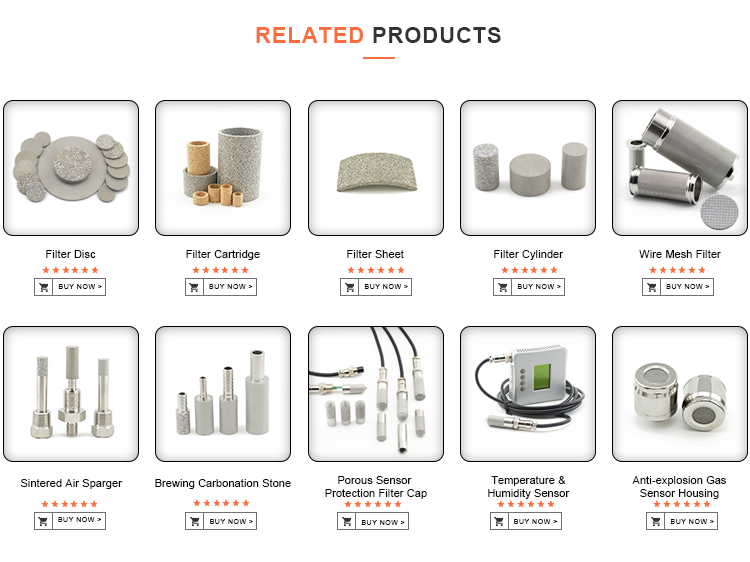

highly recommended

VIEW MORE

You may like

-

Low price nylon filter cloth 5 10 20 30 40 50 60 70 80 90 100 200 300 400 500 600 700 800 microns

-

Personalized stainless steel coffee brewing filter

-

Hot Sale Durable Stainless Steel Wire Mesh Wedge Wire Curved Screen Mesh

-

Vane demister stainless steel 304 in cooling tower

-

SS 304 10 20 30 40 50 60 80 100 mesh stainless steel ring wire mesh filter disc

-

5 10 25 30 40 50 60 70 80 90 100 150 200 250 300 400 500 600 700 800 micron nylon filter

-

100 300 400 800 micron stainless steel wheat basket for home brewing

-

Manufacturer Custom Metal Filter Basket 304 316 Stainless Steel Perforated Filter Tube

-

Medical high flow sintered porous UHMWPE PE filter element

-

40 60 100 200 mesh stainless steel 304 316 316L filter mesh cap

Other Products

-

$6.00 / piece

$6.00 / piece -

$1.00 / piece

$1.00 / piece -

$1.06 / piece

$1.06 / piece

Related Search

ss 304 solenoid valves

10 micron hydraul filter suppliers

water filter cartridge 10 micron

10 micron filter cartridge water

stainless steel wire 304

304 stainless steel csk head machine screw

stainless steel 304 thimbles

304 stainless steel machine screws pan head

stainless steel screws 304/316

304/316 stainless steel screws