Electric Industry Foundry 1 Ton Scrap Iron Induction Melting Furnace Machine For Sale

-

Supplier: Foshan Nanhai Hengyang Electric Furnace Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Eva Zhou -

Price: $7000.00 / 1 - 4 sets

$6500.00 / >=5 sets -

Min. Order: 1 set

Product details

| Dimensions (L*W*H): | 1800*1450*1350mm | Supply capacity: | 90 sets per quarter |

| usage: | Melting furnace | Maximum temperature: | 1800 degrees |

| operating hours: | 24 hours | application: | molten cast iron |

| Package preview: | Warranty: | 1 year | |

| Video shipment inspection: | if | Operating temperature: | 0-1500 degrees |

| Main selling points: | easy to operate | Origin: | Guangdong, China |

| Marketing Type: | normal product | Furnace capacity: | 1 ton |

| Weight (ton): | 1.5 tons | Power (kW): | 750 |

| Mechanical test report: | if | fuel: | electricity |

| Showroom location: | Egypt | type: | induction furnace |

| brand: | Hengyang | payment terms: | L/C, Western Union, T/T, MoneyGram, Cash |

| Core component warranty: | 1 year | Core components: | PLC, engine, motor, control board |

| Packaging Details: | Ship to the buyer's area in standard export ocean packaging pallets, and install and debug in the buyer's area | Voltage: | 380V |

| cooling method: | water cooling | port: | Guangzhou Whampoa |

| Furnace type: | induction furnace | Health status: | new |

| Melting time: | 50-60 minutes | Applicable industries: | Manufacturing plants, energy and mining industries, foundries |

Product Description

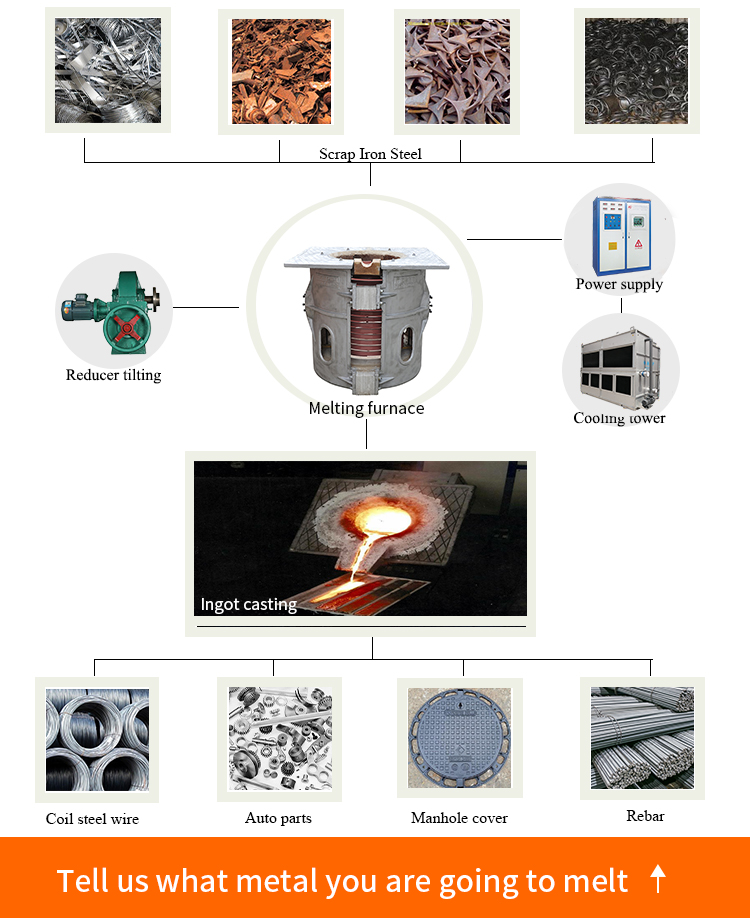

How does the furnace work?

The intermediate frequency melting furnace is mainly composed of a power supply, a furnace body with an induction coil and a crucible. Put the iron into a crucible made of refractory cement. After the power is turned on, an alternating magnetic field is generated in the induction coil, which generates an induced eddy current, which heats and melts the iron.

parameter | to unite | material |

Rated Capacity | Ton | 1 |

Maximum capacity | Ton | 1.2 |

Operating temperature | Celsius | 0-1500 |

maximum temperature | Celsius | 1800 |

power factor | 0.9 | |

rated power | kilowatt | 750 |

Rated input current | A | 1200 |

Rated input voltage | V | 380 |

IF voltage | V | 750 |

Startup success rate | % | 100 |

Rated operating frequency | kilohertz | 1-2.5 |

working noise | D b | ≤75 |

melting rate | ton/hour | 1 |

energy consumption | kWh/ton | 600 |

Water Consumption | ton/hour | 35 |

Furnace Features

1.Electric fuel, various capacity 0.05T-10T, fast melting speed, 40-60 minutes/pot.

2. Low energy consumption. Induction melting is the most energy-efficient melting method in electric furnaces.

3. Save raw materials. Our stoves cause lessburn out. itCompared with gas, oil or coal-fired furnaces, at least 20-50 kg of steel can be saved per ton of steel.

4.Substandard products are reduced by 1.5%.The application of temperature control system can achieve precise temperature control to ensure quality and capacity.

5. Environmental protection.When working, there is no harmful gas and strong light produced by the stove, and workers will no longer be smoked by coal stoves under the hot sun. Can meet the government's environmental protection requirements.

6. Easy maintenance, safe and stable.

6. Easy maintenance, safe and stable.

Comment

The parameters will be customized according to your actual situation.

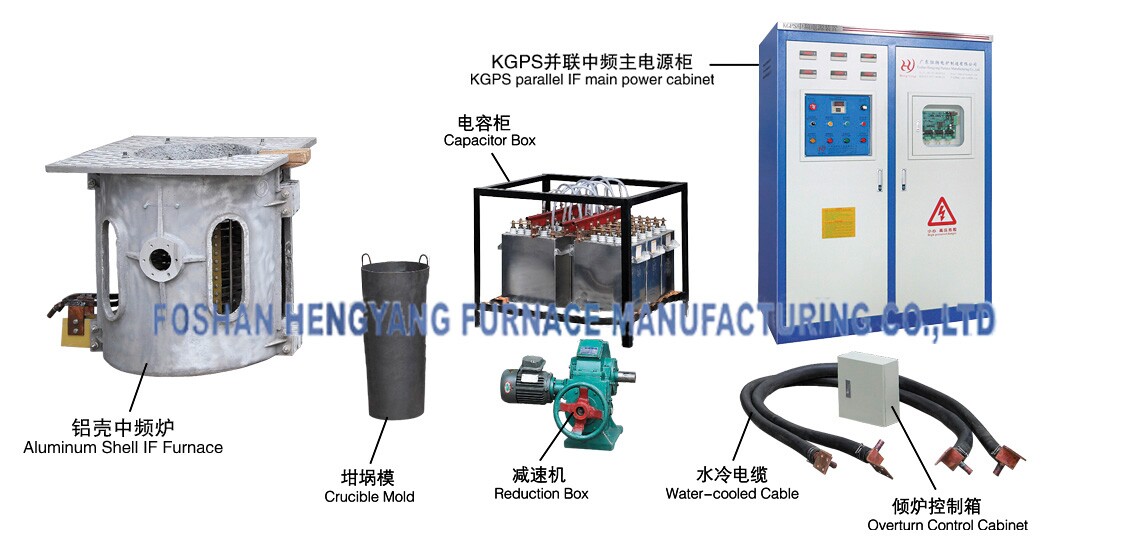

set display

One set includes power cabinet, furnace body, capacitor, reducer, tilt control board, water cooling cable and crucible.

Model (furnace capacity) | Input power 50Hz | ||||||

(furnace capacity) | rated power (kW) | Rated voltage (five) | rated current (A) | Transformer capacity (kVA) | |||

GW-0.05T | 50 | 380 | 80 | 65 | |||

GW-0.1T | 100 | 380 | 160 | 120 | |||

GW-0.15T | 160 | 380 | 256 | 250 | |||

GW-0.2T | 160 | 380 | 256 | 250 | |||

GW-0.25T | 200 | 380 | 320 | 250 | |||

GW-0.35T | 250 | 380 | 400 | 315 | |||

GW-0.5T | 350 | 380 | 560 | 400 | |||

GW-0.75T | 500 | 380 | 800 | 630 | |||

GW-1T | 750 | 380 | 1200 | 800 | |||

GW-1.5T | 1000 | 380 | 1600 | 1250 | |||

GW-2T | 1400 | 750 | 1078 | 1600 | |||

GW-3T | 2000 | 750 | 770*2 | 2500 | |||

GW-5T | 3000 | 950 | 912*2 | 4000 | |||

GW-10T | 5000 | 1000 | 1443*2 | 6300 | |||

GW-15T | 8000 | 1000 | 1155*4 | 10000 | |||

GW-20T | 10000 | 1000 | 1443*4 | 12600 | |||

GW-30T | 15000 | 1000 | 2165*4 | 16000 | |||

Comment

1. The furnace capacity is designed according to the density of 7.8g/cm³; 2.The data above are for standard furnaces. Furnaces with different power and capacity can be customized according to customer needs.

VIEW MORE

You may like

-

Best Selling Electric Arc Furnace Graphite Electrode for Electric Arc Furnace 5 Ton Refractory Electric Arc Furnace

-

Prebaked consumable carbon anode block for aluminum smelting

-

Professional production of high-quality imported high-temperature resistant belts for industrial furnaces

-

Sell Gold Smelting Furnace

-

Mini electric furnace for melting tin, silver, copper, aluminum, gold, melting furnace, melting furnace

-

Copper and aluminum scrap casting 150KG 200KG 300KG 1.5 tons for casting copper zinc lead ingot casting machine

-

High Speed Aluminum Recycling Scrap Melting Furnace Aluminum Melting Furnace

-

Ex-factory price gas melting gold furnace

-

In 2022, the new machine laboratory will use a 15kw vacuum precious metal melting furnace to smelt rhodium and boron

-

Factory supply high quality MoSi2 heating chamber modules for kilns

Related Search

scrap copper induction melting furnace

brass scrap electric induction melting furnace

copper scrap induction melting furnace for sale

copper scrap induction melting furnace

industrial printing machines for sale

scrap metal baler machine for sale

100kg induction melting furnaces

1 ton high frequency steel iron induction furnace suppliers

scrap iron power shear

scrap iron dust