Rotary 20 stations blowing slippers machine women's shoes

-

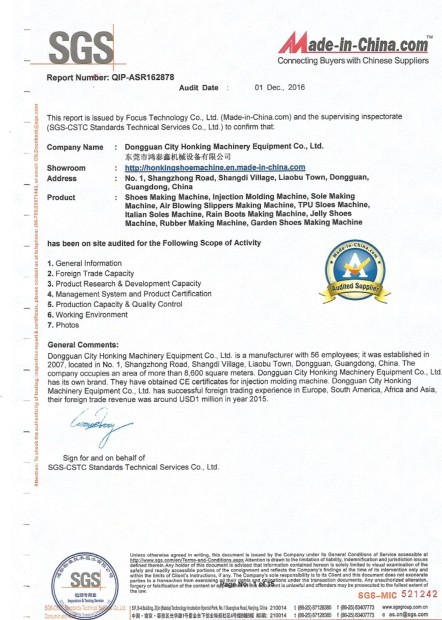

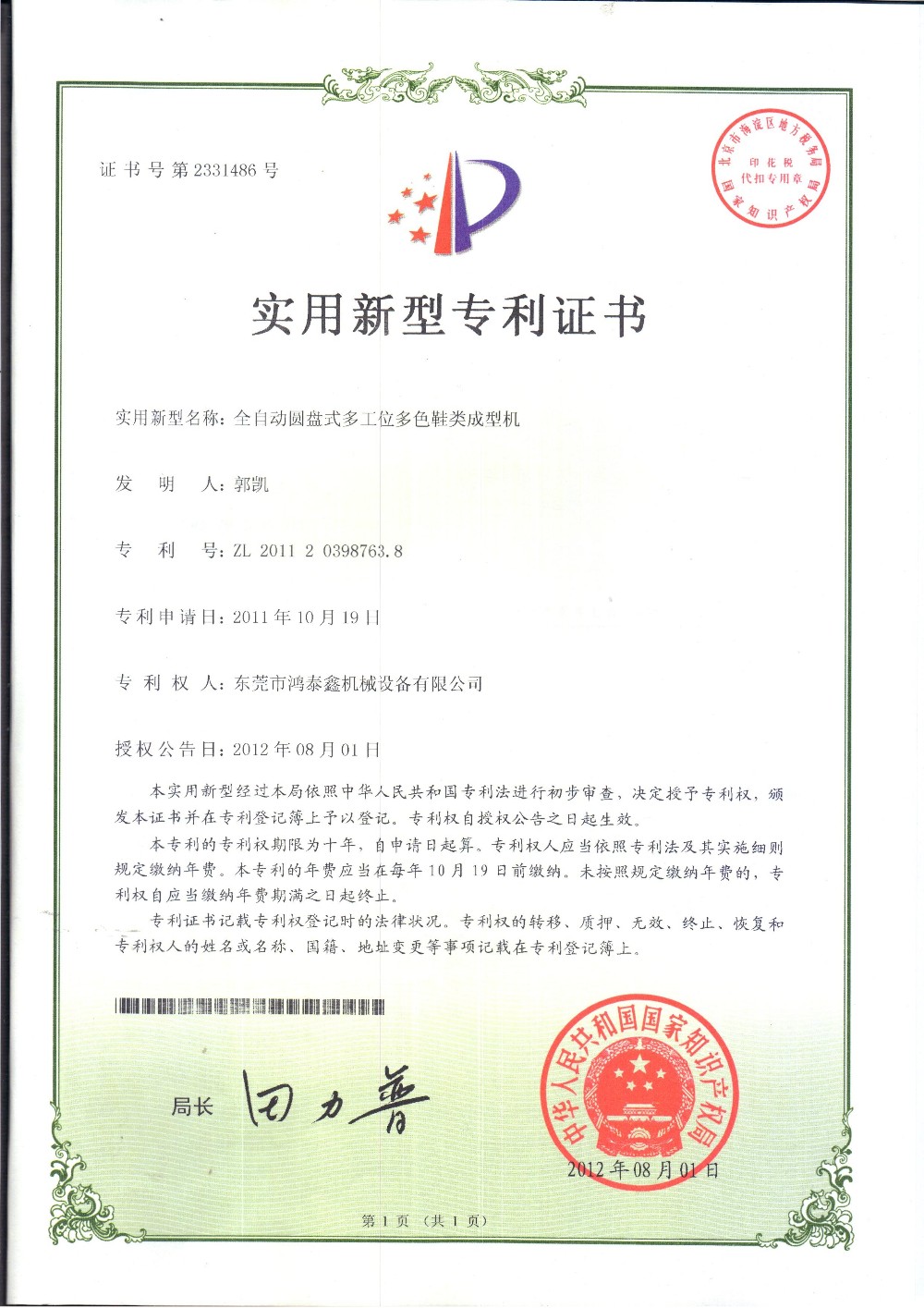

Supplier: Dongguan City Honking Machinery Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Kevin Guo -

Price: $20000.00 /set -

Min. Order: 1 set

| Applicable materials: | Plastic PVC.PCU | After-sales service provided: | Engineers available to service machinery overseas |

| Production capacity: | 80-120 pairs/hour | Packaging Details: | plastic film |

| strength: | 18.5kw | application: | making slippers |

| Name: | Rotary 24-station Slipper Blowing Machine | Health status: | new |

| Supply capacity: | Annual output of 300 slippers blowing machines | Controller: | PLC+touch screen |

| weight: | 5.5T | Material: | Plastic PVC.PCU |

| payment terms: | L/C, T/T | port: | Shenzhen |

| Partner: | Africa | type: | fully automatic |

| Product Category: | plastic shoes | Dimensions (L*W*H): | 4300x3500x26000mm |

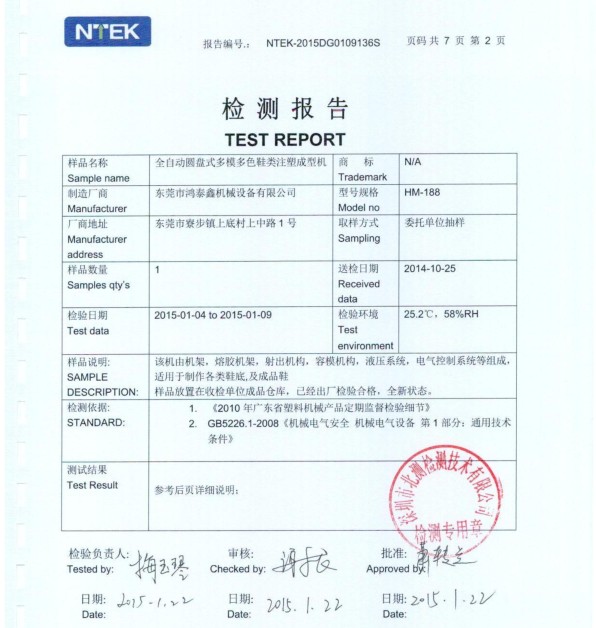

| Certification: | CE certification | Voltage: | 380V/50HZ |

| Model: | HM-188 | brand: | trumpet |

| Forming area: | shoe | Warranty: | one year |

| Origin: | Guangdong, China |

Rotary 20-station Slipper Blowing Machine

Applications

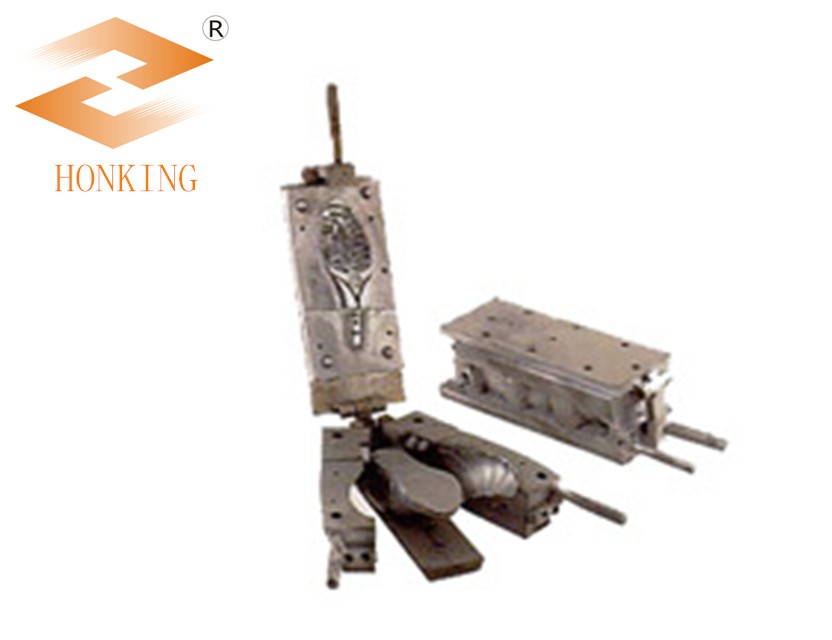

1. This machine has a special blowing device, which is suitable for thermoplastic raw materials such as PVC, PCU, and TPR. The product is light, soft and has a glossy finish.

2. Environmentally friendly, recycled materials can be mixed and used, but the product quality is the same as that of new material injection molding finished products.

3. Compact design, small footprint, high yield.

4. The data is calculated by PLC/PC, the energy is precisely controlled, the movement is stable, the speed is fast, and the yield is high.

5. The unique design can inject one-to-one molded products, which greatly improves the output.

| SpecificationRotary 20-station Slipper Blowing Machine | |||

main feature

1. This machine has a special blowing device, which is suitable for thermoplastic raw materials such as PVC, PCU, and TPR. The product is light, soft and has a glossy finish.

2. Environmentally friendly, recycled materials can be mixed and used, but the product quality is the same as that of new material injection molding finished products.

3. Compact design, small footprint, high yield.

4. The data is calculated by PLC/PC, the energy is precisely controlled, the movement is stable, the speed is fast, and the yield is high.

5. The unique design can inject one-to-one molded products, which greatly improves the output.

Rotary 20-station Slipper Blowing Machine

Name: motor

brand:Tianjin Seiko

The original:Taiwan. China

The rotary plastic PVC slipper machine motor is selected from Taiwan TJS brand. It is a factory specializing in the production of motors for more than 16 years. The motor has stable performance, energy saving and environmental protection.

Rotary 20-station Slipper Blowing Machine

Name:touch screen

brand:Wellcome

The original:Taiwan. China

Rotate the touch screen of the plastic PVC slippers making machine, we choose the brand Wecon from Taiwan, China. It is a factory specializing in the production of touch screens for more than 11 years. Its motor has stable performance and high quality.

Rotary 20-station Slipper Blowing Machine

Name:Programmable Controllers

brand:Fatek

The original:Taiwan. China

The PLC of the rotary plastic PVC slipper machine is selected from the Taiwan Wellcome brand. It is a manufacturer specializing in the production of PLCs for more than 15 years. The motor performance is stable and the quality is high.

Rotary 20-station Slipper Blowing Machine

Name:Electric valve

brand:iron

The original:Taiwan. China

For the valve of rotary plastic PVC slipper machine, we choose Taiwan FE brand. China. It is a factory specialized in PLC manufacturing for more than 9 years. Its motor has stable performance and high quality.

pre-sale service

* Inquiry and consultation support.

* Check out our factory.

* If available, please show if the machine is working properly.

After-sales service

* Training how to install the machine, training how to use the machine.

* Engineers are available to service machinery overseas.

| size | |

| weight | |

| size | |

| weight | |

product name with link

91.8%reaction speed

product name with link

91.8%reaction speed

product name with link

91.8% reaction speed

-

Injection Rubber Slipper Strap Making Machine

-

Sandals Flip Flops Making Machine Making Ladies Slippers For Sale

-

PVC TPR TPU Monochrome Blow Plastic Shoes High Elasticity Breathable Crystal Slippers Sandals Injection Molding Machine

-

PVC PU Rubber Shoes Sole Vertical Injection Molding Machine for Shoe Making

-

Used refurbished rotary shoe sole injection molding machine with new electronic parts

-

High Quality Customized Fashion Products 1 Color PVC Slippers Sandals Shoes Injection Molding Machine

-

Semi-Auto Monochrome Plastic TPR PVC Sneakers Injection Molding Machine JL-258

-

Fully automatic pu sole making machine footwear pouring production line pu sports shoes and safety shoes molding machine

-

pvc inflatable shoe machine india

Other Products

-

$22000.00 / set

$22000.00 / set