Semi-Auto Monochrome Plastic TPR PVC Sneakers Injection Molding Machine JL-258

-

Supplier: Dongguan Jinlei Shoe-Making Machine Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Andy Luo -

Price: $30000.00 /set -

Min. Order: 1 set

| Production capacity: | 260-330 pairs/hour | workstation: | 20 stations |

| Packaging Details: | Semi-Auto Monochrome Plastic TPR PVC Sneakers Injection Molding Machine Standard Export Packaging | Screw diameter: | 75mm |

| Warranty: | 2 years | place of origin; place of origin: | Guangdong, China |

| Clamping force: | 210-260 tons | port: | Shenzhen, Guangzhou, Hong Kong |

| weight: | 9000 | Showroom location: | not any |

| shoe color: | 1/2 color | Voltage: | 220v/380v/440v |

| Shoes on a trip: | 60mm | Core Components Warranty: | 1 year |

| Supply capacity: | 50 sets per month | application: | Basketball shoes, jogging shoes, casual shoes, canvas shoes, snow shoes |

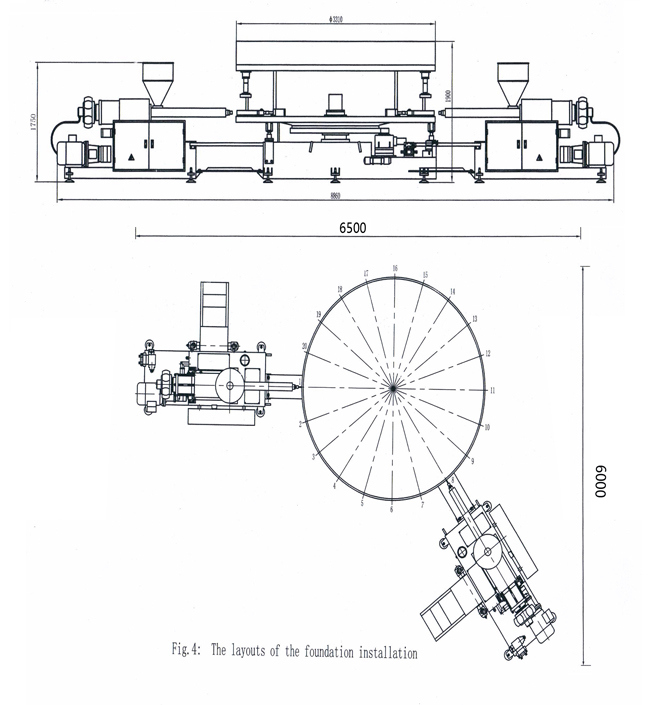

| Dimensions (L*W*H): | 6150x3350x2000mm | Marketing Type: | normal product |

| strength: | 37.5kW | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Main selling point: | easy to operate | Mechanical test report: | if |

| Core components: | PLC, engine, bearing, gearbox, motor, gear, pump | Applicable industries: | Shoe Machinery |

| After-sales service provided: | Engineers can repair machinery overseas | Last height: | 210-260mm |

| Video external inspection: | if | brand: | Kingston |

| Raw materials: | TPR/PVC | Health status: | new |

| Opening stroke: | 170mm |

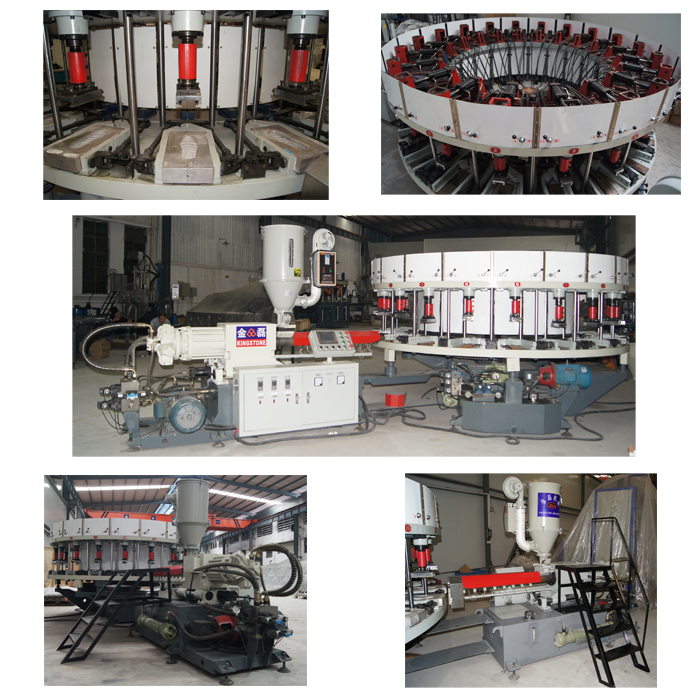

JL-258 Semi-Auto Monochrome Plastic TPR PVC Sports Shoes Injection Molding Machine

Products: Specializing in the production of basketball shoes, jogging shoes, casual shoes, canvas shoes, snow shoes and other sports shoes.

Material: Suitable for various thermoplastic raw materials, foamed or non-foamed, such as PVC and TPR.

|

Specification |

||

|

machine type |

unit |

JL-258 |

|

Clamping unit |

||

|

raw materials |

|

PVC/TPR |

|

workstation |

|

12/16/20 |

|

shoe last trip |

mm |

60 |

|

Last height |

mm |

210-260 |

|

Die size |

mm |

340×180×60 |

|

Clamping method |

|

five |

|

Injection device |

||

|

Screw diameter |

mm |

75 |

|

Screw aspect ratio |

long/deep |

20 |

|

Maximum injection volume |

cubic centimeter |

750 |

|

Turntable pressure |

MPa |

3.0 |

|

Plasticizing ability |

g/s |

40 |

|

injection pressure |

MPa |

5.0 |

|

Screw speed |

Rotating speed |

0-200 |

|

energy used |

||

|

Injector heating power |

kilowatt |

9 |

|

Hydraulic unit motor |

kilowatt |

15 |

|

total power consumption |

kilowatt |

twenty four |

|

Dimensions and Weight |

||

|

Machine size |

(L*W*H)MM |

6150×3350×2000 |

|

machine weight |

KGS |

9000 |

|

*Note: The above data is for reference only. |

||

1. The machine is controlled by PLC system, pre-plasticized by hydraulic motor and driven by full hydraulic pressure.

2. Strong plasticizing ability, temperature can be controlled automatically.

3. Using 20-point measurement, the injection volume of each station can be set according to actual needs.

4. It has the function of empty mode selection and frequency conversion operation.

5. The machine is equipped with V-shaped clamping parts.

6. The turntable runs smoothly and the speed is adjustable. Movement, plasticization and injection are independent.

7. The machine has the functions of secondary injection and selection of the final pressing and clamping sequence.

8. There are many workstations, the shoemaking time is long, and the product quality is improved.

This pvc direct injection shoe machine can be applied to sports shoes, canvas shoes, sandals, etc.

1. PVC direct injection molding.

2. High production capacity, few workers and low cost.

3. Can be used for sports shoes, canvas shoes, school shoes, sandals, etc.

4. Good product on the market.

5. PLC control, more accurate production.

A 40HQ container is required for machine loading.

The machine weight is 9 tons.

-

Injection Rubber Slipper Strap Making Machine

-

Sandals Flip Flops Making Machine Making Ladies Slippers For Sale

-

Rotary 20 stations blowing slippers machine women's shoes

-

PVC TPR TPU Monochrome Blow Plastic Shoes High Elasticity Breathable Crystal Slippers Sandals Injection Molding Machine

-

PVC PU Rubber Shoes Sole Vertical Injection Molding Machine for Shoe Making

-

Used refurbished rotary shoe sole injection molding machine with new electronic parts

-

High Quality Customized Fashion Products 1 Color PVC Slippers Sandals Shoes Injection Molding Machine

-

Fully automatic pu sole making machine footwear pouring production line pu sports shoes and safety shoes molding machine

-

pvc inflatable shoe machine india

Other Products

-

$20000.00 / set

$20000.00 / set