DZP Grinding Wheel Polishing Machine, Alloy Wheel Polishing Machine

-

Supplier: Xinxiang Dongzhen Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr Robert LEO -

Price: $4300.00 / 1 - 4 sets

$4000.00 / >=5 sets -

Min. Order: 1 set

Product details

| application: | polishing | Video shipment inspection: | if |

| Applicable industries: | Energy and Mining, Home Use, Printing Store, Food and Beverage Store, Hotel, Food and Beverage Factory, Retail, Farm, Construction, Other, Clothing Store, Restaurant, Building Supply Store, Food Store, Advertising Agency, Machinery Repair Shop, Manufacturing Factory, wheel repair workshop | Local service location: | Philippines, Brazil |

| Core components: | motor | Machine volume: | 100L-900L |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | place of origin; place of origin: | Henan, China |

| After warranty service: | Video technical support, online support | After-sales service provided: | On-site installation, commissioning and training, online support, free spare parts, video technical support |

| Material: | High wear-resistant material | Showroom location: | Philippines, Brazil |

| Supply capacity: | 2000 pieces per month | Core component warranty: | 1 year |

| strength: | 0.25-7.5kw | brand: | QUR |

| Marketing Type: | New Products 2020 | Package preview: | |

| Weight (kg): | 600 | Warranty: | 1 year |

| color: | according to order | Packaging Details: | 1. Stretch film and wooden box packaging 2. According to customer requirements |

| State of health: | new | port: | Qingdao Guangzhou Shenzhen Shanghai Ningbo Suzhou Dalian Rizhao Tianjin Yingkou |

| Mechanical test report: | if | motor: | High quality vibration motor |

| job type: | 3D vibration | Power (kW): | 1.9 |

| Main selling points: | easy to operate |

Product Description

Vibratory finishing machines for metalworking have an annular chamber that holds the abrasive (stone) and workpiece. When the machine is working, it will produce three-dimensional high-frequency vibration. The grinding stone and the workpiece roll forward in a spiral shape and grind each other during the rolling process. This enables workpieces to be deburred, chamfered, polished and cleaned. Instead of traditional cloth wheel polishing, vibration polishing machines for metal processing can save a lot of labor costs, and

reduce manufacturing cost. It can also cooperate with mass production to improve and stabilize product quality.

reduce manufacturing cost. It can also cooperate with mass production to improve and stabilize product quality.

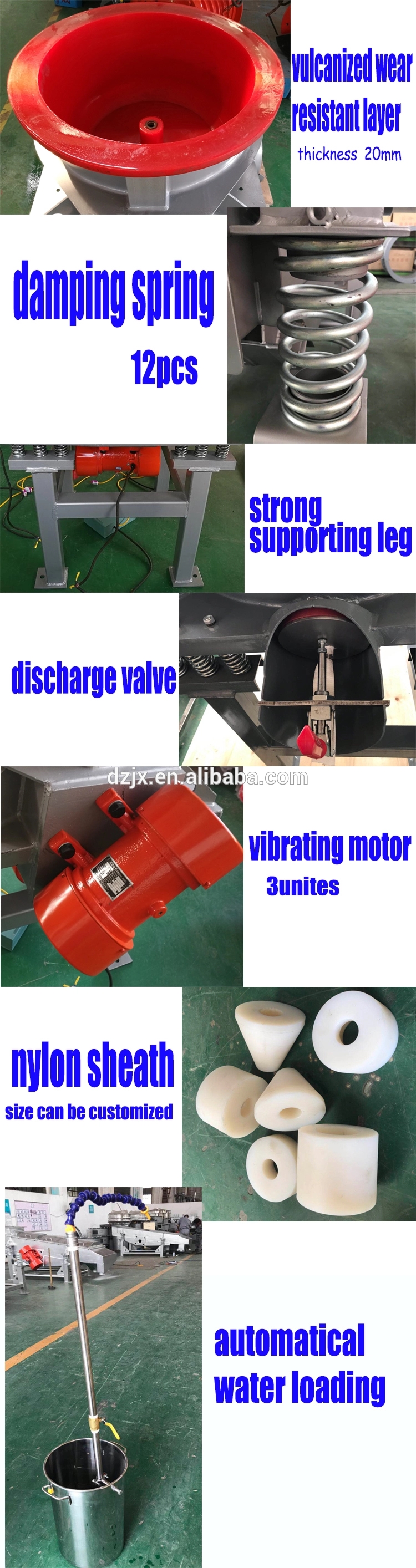

detailed image

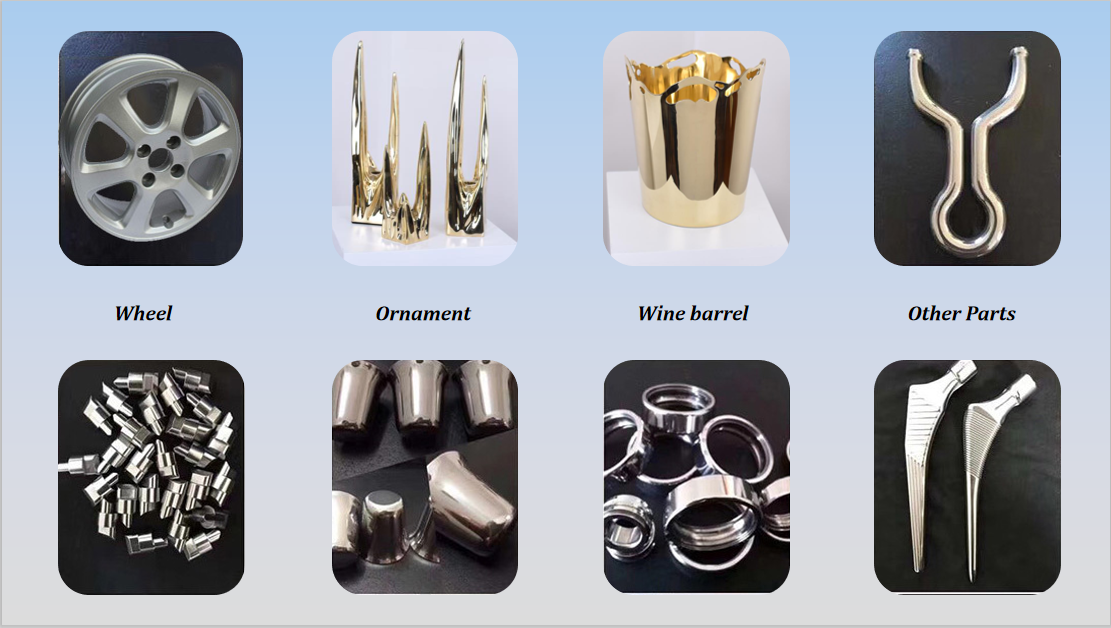

application

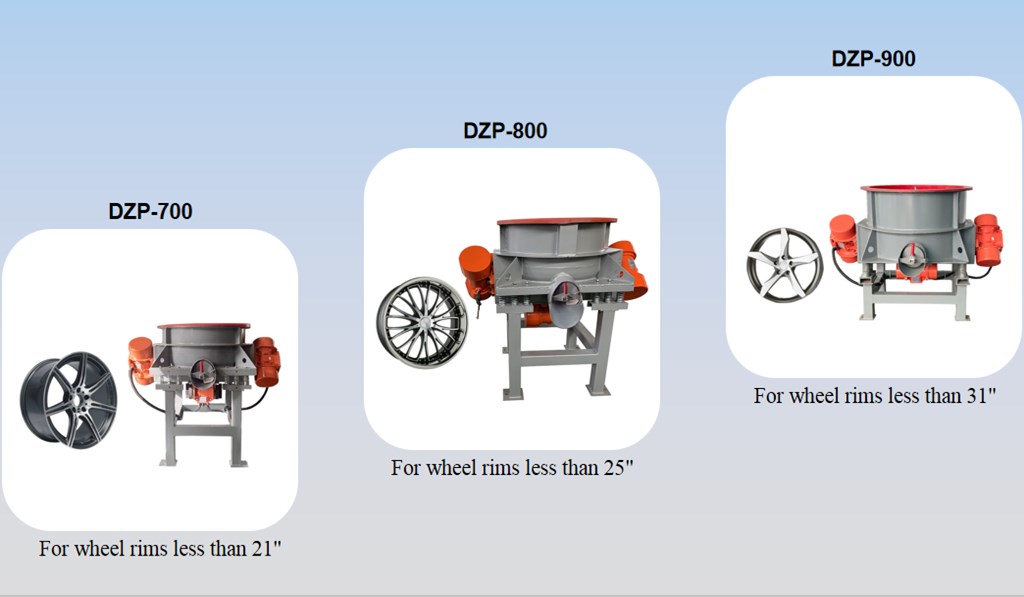

technical parameter

Model | Effective diameter (mm) | Bucket height(mm) | bucket capacity (l) | Motor power (kw) |

DZP-700 | 660 | 350 | 120 | 0.55*3 |

DZP-800 | 760 | 350 | 160 | 0.55*3 |

DZP-900 | 860 | 500 | 280 | 1.9 |

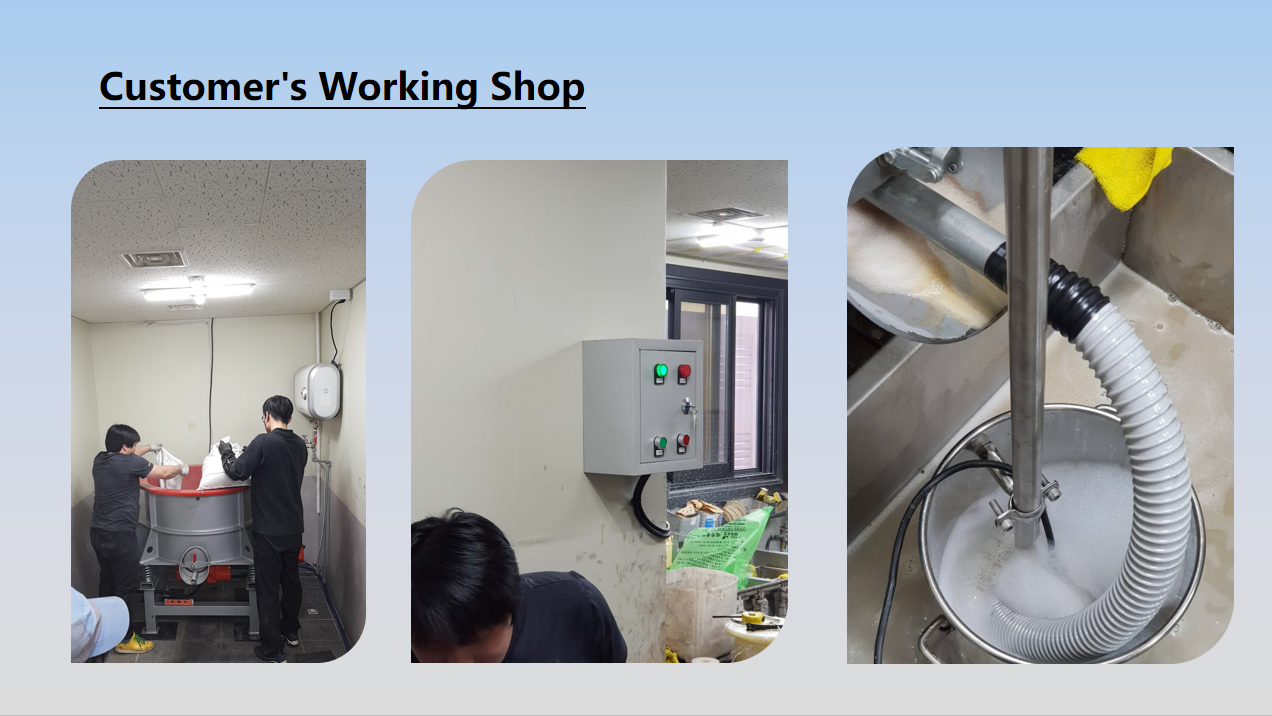

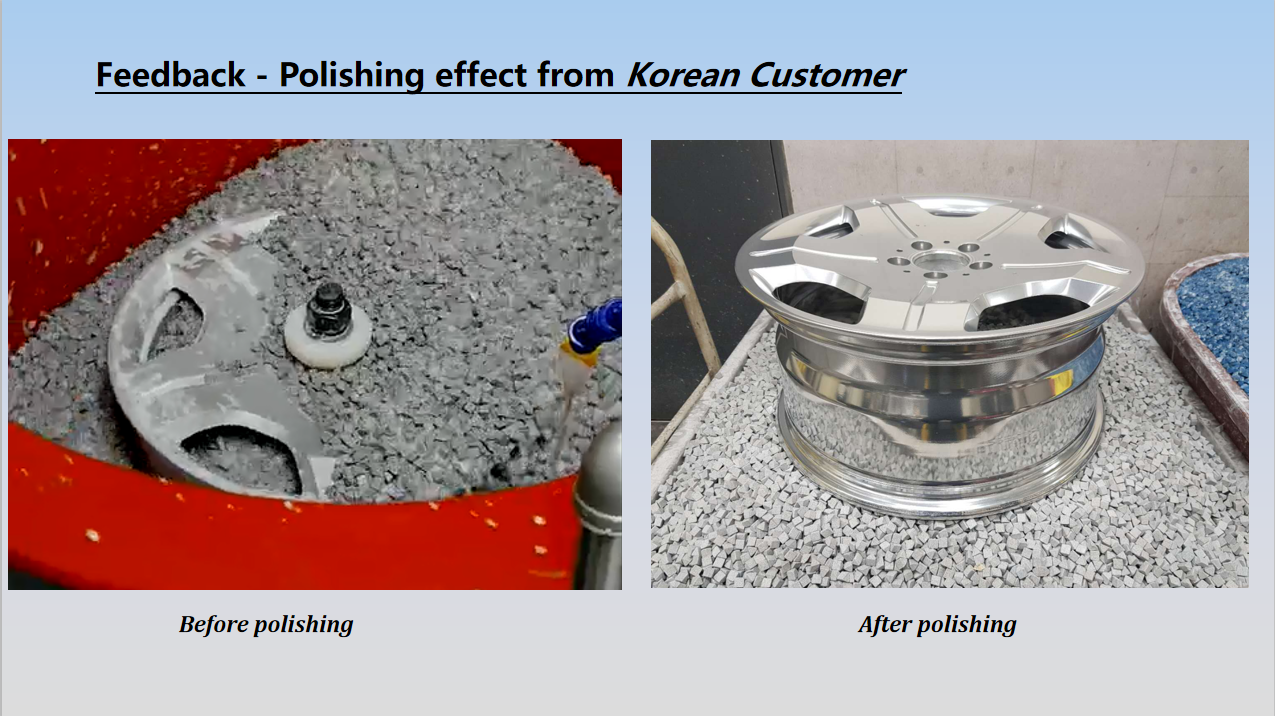

the feedback

VIEW MORE

You may like

-

Simple Vibration Polishing Machine Rock Tumbler Machine Vibration Tumbler Machine

-

2022 80L Capacity Abrasive Grinding Vibrating Wheel Polisher For Metal Deburring Polishing Various Metal Or Non-Metal

-

TY-24LX grinding and polishing machine

-

Alloy car rim vibration polishing machine

-

KARVA Brand 18 Inch 3HP Grinder Electric Concrete Floor Grinder For Granite Cement Floor Polisher

-

CE Approved Wet Dry Magnetic 3 in 1 Desktop Mini Jewelry Magnetic Tumbler Jewelry Polishing Tool

-

12" Precision Automatic Grinding/Polishing Machine with Two 4" Semiconductor Wafers and Ceramic EQ-Unipol-1202 Workstation

-

Small mini desktop abrasive belt stainless steel metal aluminum plate plate deburring polishing polishing machine

-

Volume Finishing Machine Alloy Wheel Polishing Machine New Design For Luggage Wheel

-

best selling aluminum truck rim polisher, metal polisher

Other Products

-

$990.00 - $1090.00 / set

$990.00 - $1090.00 / set -

$1400.00 - $1500.00 / set

$1400.00 - $1500.00 / set -

$1950.00 - $2000.00 / set

$1950.00 - $2000.00 / set -

$8600.00 / set

$8600.00 / set -

$600.00 / set

$600.00 / set -

$900.00 / set

$900.00 / set

Related Search

diamond grinding wheel polishing

grind and polish floor machin suppliers

concrete grinding and polishing machine

sali brand grinding wheel

grinding wheel

diamond grinding wheel

125mm resin grinding wheel metal

flexible grinding wheel disc stone

t27 5 inch grinding wheel

abras metal grind wheel suppliers