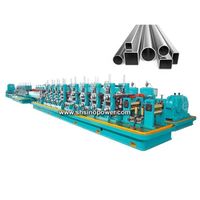

ERW tube mill entry section

-

Supplier: Jiangsu New Victor Industrial Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Jing Lin -

Price: $100000.00 /set -

Min. Order: 1 set

Product details

| Pipe Thickness: | 0.2~12mm | Health status: | new |

| Port of shipment: | Shanghai Port | useful life: | over 30 years |

| Mechanical test report: | if | Warranty: | 1 year |

| Certification: | CE ISO9001 | Video shipment inspection: | if |

| payment terms: | L/C, D/P, T/T | Pipe material: | Carbon steel |

| Main selling points: | long lasting | place of origin; place of origin: | China |

| Control System: | PLC+man-machine interface+touch screen | Core component warranty: | 3 years |

| Pipe diameter: | 4~273mm | Core components: | PLC, bearings, motors, water pumps |

| Applicable industries: | ERW Tube Mill | Packaging Details: | Seaworthy packaging |

| Weight (kg): | 3000 | Showroom location: | Egypt, Canada, Turkey, USA, Philippines, Saudi Arabia, Indonesia, Pakistan, India, Thailand, Morocco, Kenya, Argentina, Colombia, Algeria, Bangladesh, South Africa, Kazakhstan, Nigeria, Uzbekistan, Malaysia, Australia |

| Type of machine: | Tube mill production line | After-sales service: | On-site installation and training |

| Pipe shape: | Different sizes can be produced on one machine | product name: | ERW tube mill entry section |

| Marketing Type: | Hot Products of 2022 |

Inlet part of tube mill

We supply all equipment to be integrated into the inlet section of the tube mill:* Single and double head decoilers & hydraulic and pneumatic decoilers

* Flattening machine

* Hydraulic and pneumatic shearers and butt welders

* Vertical Cage Accumulator & Horizontal Loop Accumulator & Floor Type Horizontal Spiral Loop Accumulator

Product Description

Uncoiler series products

The uncoiler is the key equipment in the tube rolling production line. It is mainly used to support the strip steel coil, and it can be matched with the end leveler to feed the strip steel into the leveler. The expansion methods include manual, pneumatic and hydraulic.

Single head hydraulic uncoiler

Single head hydraulic uncoiler

Double head pneumatic uncoiler

Double head hydraulic uncoiler

Flattening machine

Shearers and Butt Welders

Connect the cut steel strips at the tail end of the front roll and the top end of the back roll, and weld them together by CO2 gas shielded welding to keep the welding line running continuously.

Pneumatic shearer butt welding machine

Hydraulic Shearer Butt Welding Station

Gantry Shearer & CO2Butt Welding Station

loop accumulator

This machine is used in the pipe machine production line, between the shear welding machine and the main machine (sizing machine), its function is to prepare the next coil of strip steel and butt welding storage from uncoiling and shearing after the first coil of strip steel is used up Sufficient steel strips are required to ensure the continuous production of the host machine (sizing machine).

Vertical cage accumulator

Horizontal circulation accumulator

Floor-mounted spiral circuit accumulator

Jiangsu New Victor Industrial Co., Ltd. is a welded pipe production line manufacturer with a history of more than 30 years.We can provide a complete tube mill production line. We also have experience in turnkey projects.

Tube mill production line products

1. The inlet part of the tube mill

2. Horizontal cycle accumulator

3. Tube forming and sizing section

4. Flying saw cutting equipment

5. Conveyor table

6. Automatic palletizing and packaging machine

Features of ERW tube mill:

Durable and non-deformable base

The thick steel plate is welded together as a whole, and tempered twice for more than 4 hours to ensure that the machine will not deform for a long time.

Stable Transmission System

Spiral bevel gear, drum gear coupling, gear teeth carburized and quenched, making the transmission system stable and efficient

And wear-resistant, with higher load capacity and lower noise

And wear-resistant, with higher load capacity and lower noise

long bearing life

Equipped with a grease nozzle for bearing lubrication, which greatly improves the bearing life.

Automatic roller quick change system

Online automatic quick roll change system, change roll in 10 minutes and resume production in 20 minutes.

VIEW MORE

You may like

-

Erw MS pipe making machine for manufacturing steel pipe metal pipe production line manufacturer

-

Fly cold saw gear box

-

China factory steel pipe factory stainless steel pipe making machine/pipe

-

HFH Street Lamp Pole Automatic Welding Production Line

-

Manufacturer Price ERW Tube Making Machine

-

High frequency welding stainless steel round tube welding machine tube mill equipment

-

Foshan YXH round square rectangle available stainless steel pipe rolling line steel pipe making machine iron pipe making machine

-

Metal Tube Mill / ERW Steel Tube Mill

-

High quality big discount high frequency welded steel pipe making machine for iron carbon galvanized steel pipe

-

Steel pipe/tube forming machine

Other Products

-

$100000.00 / set

$100000.00 / set -

$100000.00 / set

$100000.00 / set -

$100000.00 / set

$100000.00 / set -

$10000.00 / set

$10000.00 / set -

$100000.00 / set

$100000.00 / set -

$90000.00 / set

$90000.00 / set