Complete and easy-to-operate LPG cylinder production line

-

Supplier: Wuxi Hansheng Pressure Vessel Industrial Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Kelly Huang -

Price: $149999.00 /set -

Min. Order: 1 set

Product details

| Core components: | PLC, engine, bearing, gearbox | brand: | HS |

| Showroom location: | not any | Dimensions (L*W*H): | 2000*1900*1500mm |

| port: | Shanghai | Working temperature(℃): | 300 - 800°C |

| Design pressure (MPa): | custom made | Packaging Details: | Standard Airworthy Packaging |

| Applicable industries: | manufacturing plant | Automatic level: | automatic |

| Maximum working pressure (MPa): | custom made | Original volume: | 2.5~3mm, Q235, HP295 |

| weight: | 3000 | Cylinder Thickness: | 2.5~4mm or customized |

| productivity: | 500~2500 cylinders/day | Voltage: | 380V |

| capacity: | custom made | Main selling points: | easy to operate |

| Video shipment inspection: | if | Galvanized wire: | 2mm |

| Marketing Type: | New Products 2022 | Combustion gaseous fuel: | LPG/LNG/Diesel |

| Mechanical test report: | if | Warranty: | 1 year |

| Health status: | new | design standards: | custom made |

| Outer material: | steel | place of origin; place of origin: | Jiangsu, China |

| strength: | 35 kW | payment terms: | L/C, Western Union, D/P, D/A, T/T |

| Wire: | 1.2 mm | Core component warranty: | 1 year |

| product name: | LPG production line | Package preview: | |

| Volume (cubic meter): | custom made | Supply capacity: | 10000000 pieces per quarter |

| Internal material: | steel |

Product overview

LPG production line

1 | semi-automatic | 1000 cylinders/8 hours | 1 set | 4 months |

2 | semi-automatic | 2000 cylinders/8 hours | 1 set | 4 months |

3 | fully automatic | 1000 cylinders/8 hours | 1 set | 4 months |

4 | fully automatic | 2000 cylinders/8 hours | 1 set | 4 months |

3. Automatic trimming machine

This machine is reliable in performance and easy to operate.

Motor power: 5.5KW

Air pressure: 0.6Mpa

Processing time: 20s

Machine weight: 1.5 tons

Motor power: 5.5KW

Air pressure: 0.6Mpa

Processing time: 20s

Machine weight: 1.5 tons

4. End disc neck cleaning machine

Motor power: 7KW

Air pressure: 0.6Mpa

Processing time: 15s

Machine weight: 1.5 tons

Air pressure: 0.6Mpa

Processing time: 15s

Machine weight: 1.5 tons

5. Hole punching machine

Drill holes in the cylinder head

Electric power: 5.5KW

Punching speed: 180pcs/hour

Machine weight: 1.5 tons

Electric power: 5.5KW

Punching speed: 180pcs/hour

Machine weight: 1.5 tons

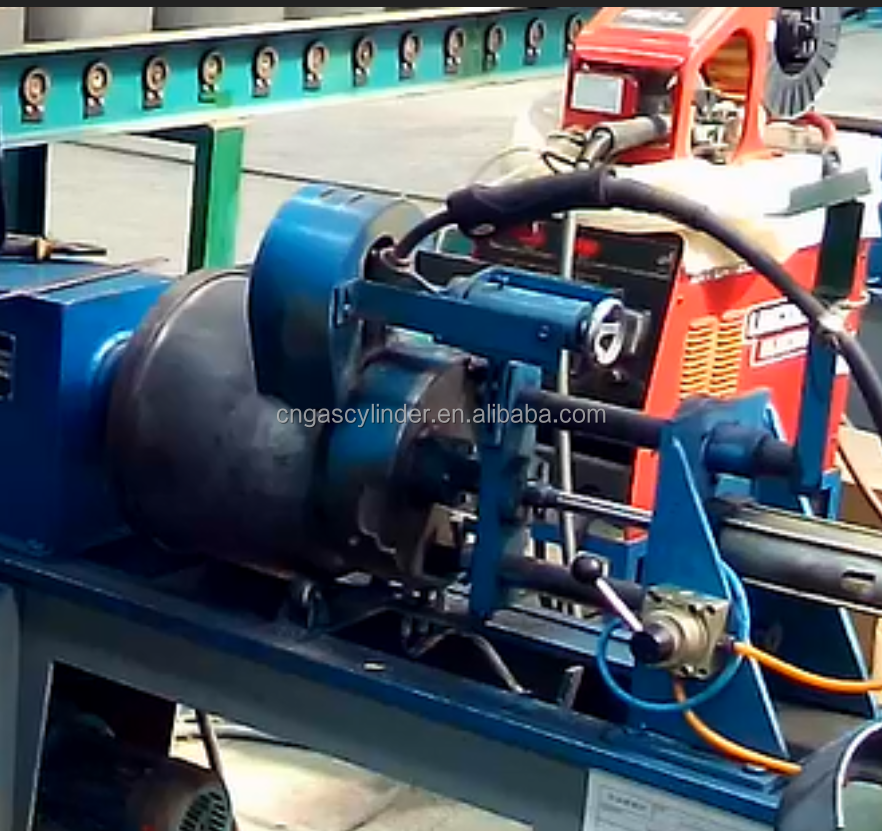

6. Valve seat welding machine

Complete welding of valve seat ring joints.

Ensure that the molding is uniform, the appearance is good, the weld penetration and weld width meet the process requirements, and the clamping is convenient.

Using submerged arc welding technology, one ring welding

7. Handle welding machine

Complete the automatic welding of the ring seam of the cylinder bottom. Ensure concentricity, uniform molding, good appearance, weld penetration and weld width meet the process requirements, and easy clamping. CO2 gas shielded welding process, one welding is completed.

8. Base welding machine

Motor power: 0.55KW

Air pressure: 0.5-0.7Mpa

Voltage: 380V

Welding speed: 15s/pcs

Machine weight: 1.5 tons

Steel plate thickness: 2-4mm

Air pressure: 0.5-0.7Mpa

Voltage: 380V

Welding speed: 15s/pcs

Machine weight: 1.5 tons

Steel plate thickness: 2-4mm

9. Assembly machine

Assemble the two halves of the cylinder together and prepare it for welding

Motor power: 0.25KW

Air pressure: 0.5-0.7Mpa

Voltage: 220V

Machine weight: 1.5 tons

Motor power: 0.25KW

Air pressure: 0.5-0.7Mpa

Voltage: 220V

Machine weight: 1.5 tons

16. Powder coating line

Working voltage: 380V, 50Hz

Air pressure: 0.4~0.6Mpa

Tower power: 15KW

Work efficiency: 180pcs/hour

Air pressure: 0.4~0.6Mpa

Tower power: 15KW

Work efficiency: 180pcs/hour

17. Printing press

Printing size (length*width): 700*600mm

Production efficiency: 2pcs/min

Ink consumption: ≤2g/pc

Weight: 0.5T

Production efficiency: 2pcs/min

Ink consumption: ≤2g/pc

Weight: 0.5T

LPG cylinder blanking and body forming line

At the heart of the forming line is a versatile double-action hydraulic deep-drawing press that turns round blanks into half cylinders, which are punched by single-action double-action punching on our presses or by our The design combination of deep drawing, punching and punching dies directly from the coil. The edges of the upper and lower halves are further processed to perfection by our trimming and splicing machines, which stem from our sheet metal forming expertise, making them suitable for body seam welding after degreasing.

LPG half bottle forming line

1. Cylinder block automatic production line, from uncoiler to deep drawing, jogging and round welding.

A: Fully automatic + robot automatic feeding

B: 1000pcs/ 2000pcs capacity according to your needs

C: only need 3-5 people at most (only for changing welding wire/nozzle)

D: Video/laser tracking + patented Panasonic welding machine

E: The workshop saves land, cutting/jogging/polishing one machine with multiple functions

A: Fully automatic + robot automatic feeding

B: 1000pcs/ 2000pcs capacity according to your needs

C: only need 3-5 people at most (only for changing welding wire/nozzle)

D: Video/laser tracking + patented Panasonic welding machine

E: The workshop saves land, cutting/jogging/polishing one machine with multiple functions

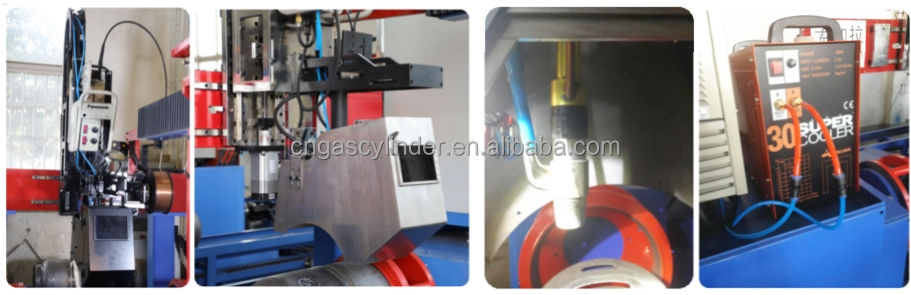

Liquefied Petroleum Gas Cylinder Forming Welding Line

The submerged arc welding technology is applied to the welding of the half of the valve body on the seam welding machine, usually used for the welding of the valve seat and the upper half of the cylinder. Welding automation units with reliable welding power packs and control units are used to achieve the degree of automation required for uncompromising welding quality and the production capacity required by each customer. MIG/MAG welding techniques are used to weld the foot ring and guard ring to the body halves. Welding is the most critical link in the production line, which ensures the best performance and good quality of the cylinder. Our welding machinery is the best gas cylinder and pressure vessel welding equipment in China, and also ranks first in the world.

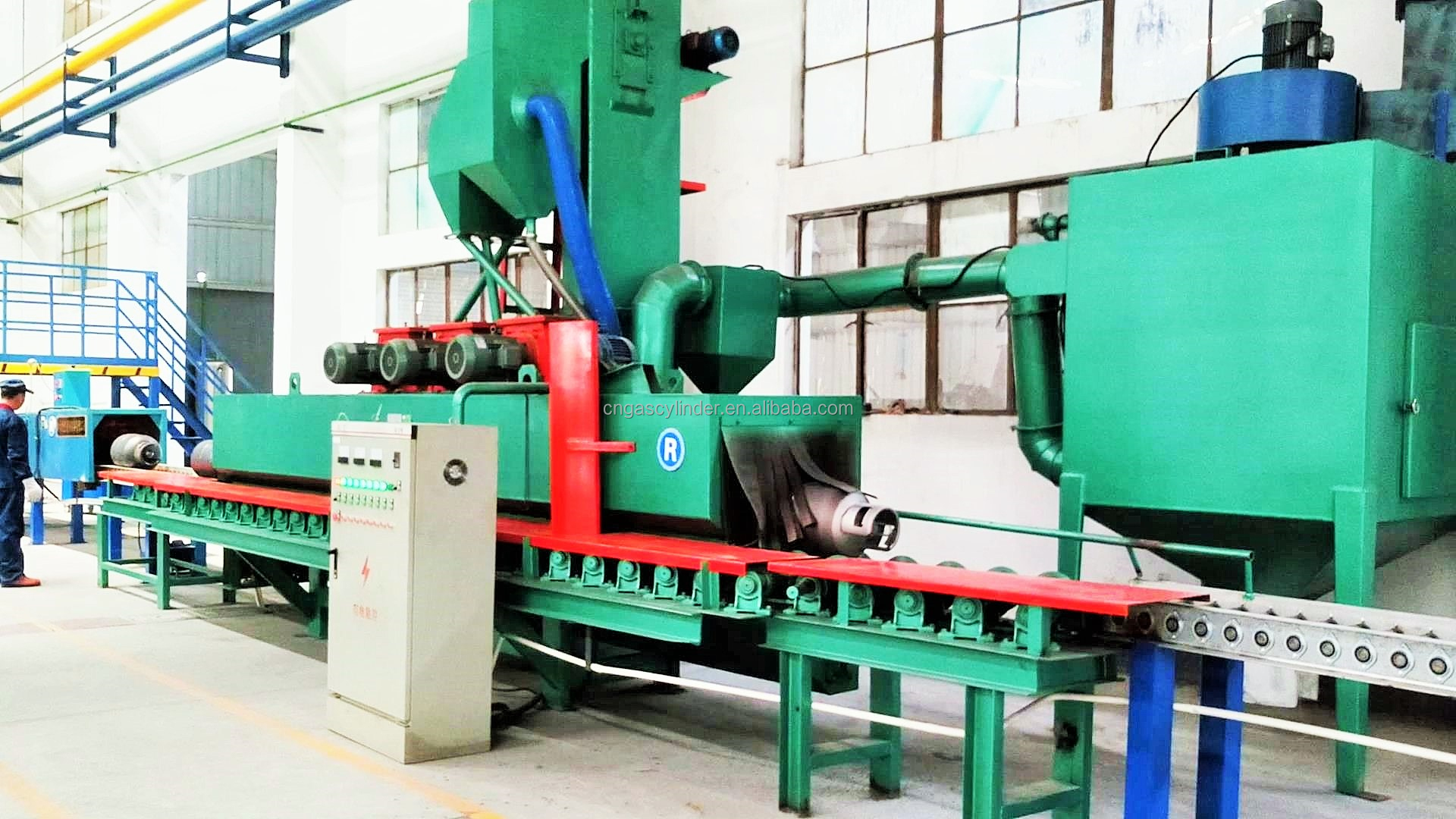

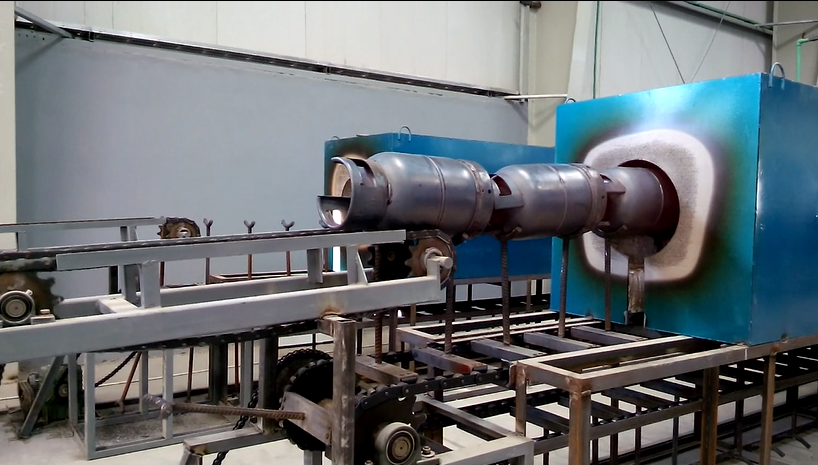

The fully automatic welding machine includes socket welding, handle/neck welding, bottom ring welding, and circumference welding, all machines work automatically, half cylinders are conveyed by mechanical arms and chains, this system really saves a lot of labor costs and improves work efficiency obviously. In order to re-relive all the stresses caused by the forming and welding operations, the cylinders pass through a heat treatment furnace where they are exposed to a temperature of 930 º C for a certain period of time before being gradually cooled.

LPG cylinder hydraulic test line and other auxiliary equipment

The surface of the LPG cylinder is shot blasted by a shot blasting machine to remove the scale generated by the heat treatment operation, and prepare the painted and/or galvanized surface for customers who require galvanizing before painting. The double layer overcured spraying of the cylinders is achieved automatically by a robotic paint application system in the coating line as the cylinders pass primary and final coats on an overhead conveyor system separated by a flash channel before curing in the canopy Modern paint curing oven in the spray cabinet type.

After the cylinders are weighed and marked, the valves are installed by an automatic torque control tightening machine and tested for leaks in the valve area by a pneumatic leak testing machine on the finishing line. One of the international standards called batch quality control equipment is the burst expansion test device, which can measure the volume expansion ratio and the burst pressure, which fully meets even the most stringent requirements.

Timely and satisfactory overseas installation services

We have rich experience in overseas installation and commissioning work, and we always send highly skilled engineers to assist our customers to run the machines smoothly and quickly.

VIEW MORE

You may like

-

Oil Test Separator Three Phase Separator ASME Pressure Vessel

-

household lpg cooking gas tank

-

Hot sale stainless steel sanitary manhole cover food grade water tank round manhole cover

-

2 liter water pump pressure tank

-

Compressed Natural Gas Cylinders for Vehicles (CNG-1)

-

China factory price 1000 gallon home propane tank

-

100m3 LPG storage tank liquefied petroleum gas tank manufacturer

-

Superior Manufacturer 100m3 Lpg Tank for LPG Gas Storage Tank iso tank container

-

25000 litres LPG gas skid refill stations with full set valves and LPG gas tank

-

lpg cooking gas filling station lpg filling plant for sale

Other Products

-

$1500000.00 / set

$1500000.00 / set

Related Search

easy to operate for diesel generator sets

easy to operate light weight small

easy to operate machinery

easy to us interfac suppliers

easy to clean ptfe mesh conveyor belt

reading and learning to read

easy to read books suppliers

production lines and machinery food

lpg cylinder

lpg cylinder regulator