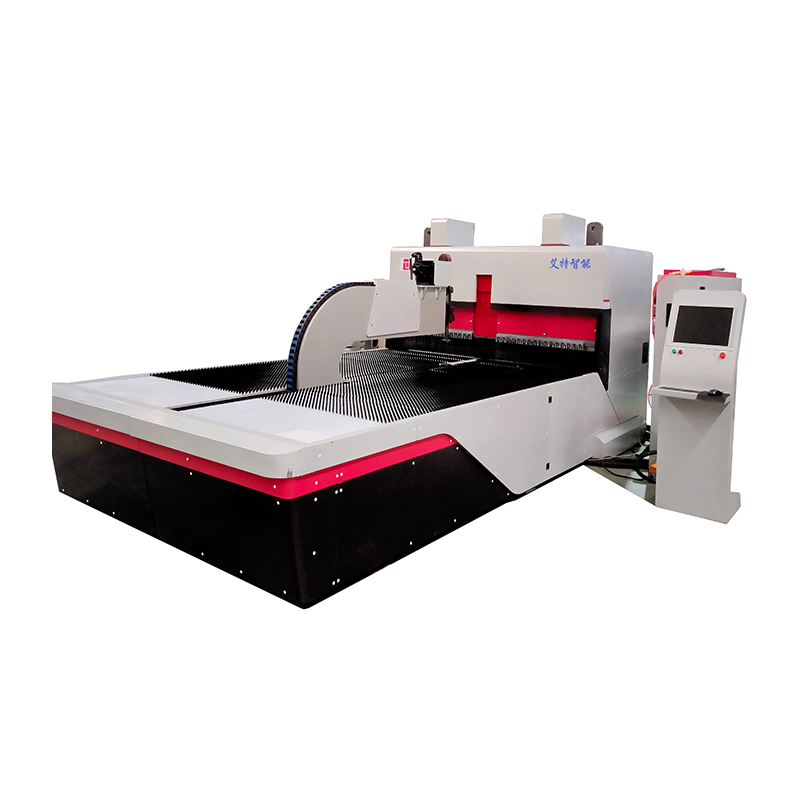

2022 Hot Selling Sheet Metal Bending Machine Kitchen Cabinet CNC Panel Bending Machine

-

Supplier: Qingdao Aiotek Intelligent Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Ms Liting Wang -

Price: $70000.00 /set -

Min. Order: 1 set

Product details

| Bending thickness (mm): | 0.1 - 3 mm | Warranty: | 1 year |

| Marketing Type: | normal product | Bending length (mm): | 2500 mm |

| year: | 2022 | product name: | Flexible bending center |

| Weight (kg): | 20 | After Warranty Service: | Online support |

| Packaging Details: | Seaworthy packaging | brand: | Ayote |

| type: | AT-S2500 | Health status: | new |

| Mechanical test report: | if | After-sales service provided: | Online support |

| Core Components Warranty: | 1 year | Video external inspection: | if |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | automation: | automatic |

| Certification: | ce | Supply capacity: | 2 sets per month |

| Showroom location: | Korea, Japan | port: | Qingdao |

| payment method: | letter of credit, wire transfer | Material/Metal Finishing: | Aluminum alloy, stainless steel, carbon steel, aluminum |

| Main selling point: | automatic | Applicable industries: | Energy & Mining, Manufacturing, Food & Beverage Plants |

| place of origin; place of origin: | China | Dimensions (L*W*H): | 6200*3300*2500 |

| size: | 6200*3300*2500 | Core components: | PLC, Bearings, Gearboxes, Motors, Gears |

Product Description

AIOTEK BENDING: AT-S2500 Panel Bending Center

All-electric servo CNC intelligent flexible bending center

The whole machine includes four main parts:

(1). The bottom assembled and welded heavy-duty structure adopts ultra-high-strength steel integrally assembled and integrally welded, giving the machine a huge tonnage weight and a stable center of gravity. These features ensure that our machines have long-term bending stability accuracy, better reliability and good durability. The whole structure has also undergone heat treatment such as stewing technology and tempering treatment, which makes the structure have strong rigidity, eliminates internal stress, eliminates stress, especially prolongs and prolongs the service life of the machine and improves its positioning accuracy.

(2). Upper assembly welded heavy-duty structure with tabs and hinged vanes that are manufactured, welded and treated the same as the bottom structure.

(3). Mobile assembly welded heavy duty supports for up and down curved blades that are assembled, welded and handled in the same way as the bottom structure.

(4). Feeding system: The worktable is equipped with a C-shaped mobile powerful clamping arm, which can flexibly control and operate the sheet metal panel, and can also choose a mobile suction cup to flexibly control and operate the sheet metal panel.

(5). The workbench also has enough bristle brushes and rolling stainless steel beads to protect the sheet metal panels while machining.

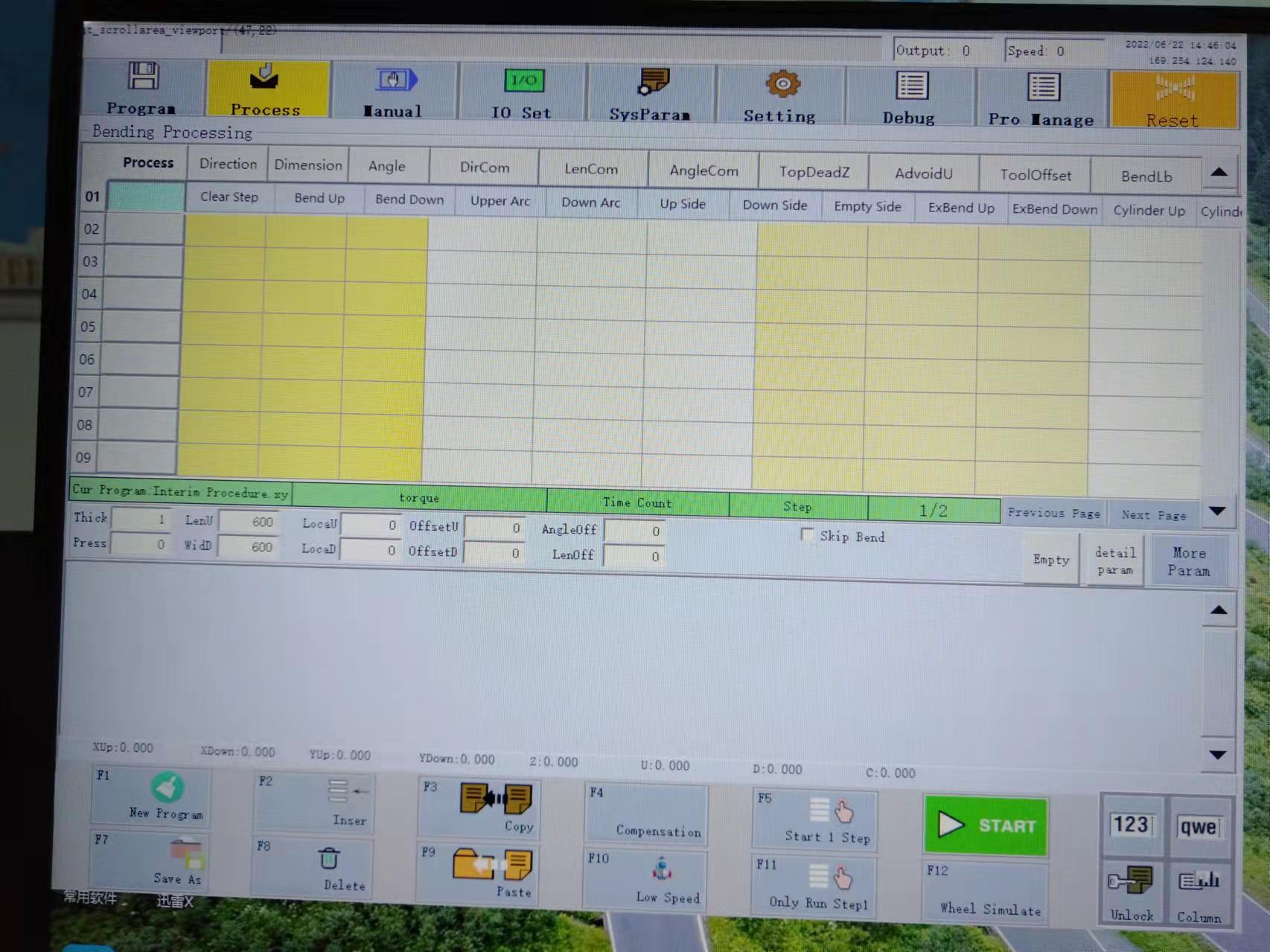

1. The bending program is simple, easy to understand and operate, and can flexibly and easily complete various complex bending workpieces.

2. Fast and convenient, the robot has a high degree of automation,

High machining accuracy.

4. Significantly save a lot of labor and tool costs in processing compared to traditional bending machines.

5. SERVO system, energy saving and high efficiency.

6. The bending length can reach 2500mm, and the bending height can reach 190mm

2. Fast and convenient, the robot has a high degree of automation,

High machining accuracy.

4. Significantly save a lot of labor and tool costs in processing compared to traditional bending machines.

5. SERVO system, energy saving and high efficiency.

6. The bending length can reach 2500mm, and the bending height can reach 190mm

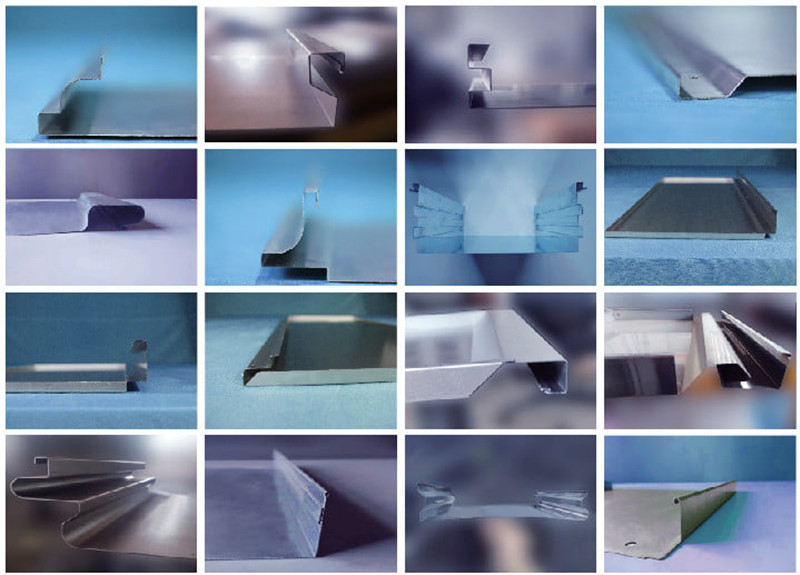

detailed picture

System operation interface.

Up and down bending tools for manufacturing and welding heavy duty brackets

Hard press tool and two coincident crimping plates on each side to hold down the panel securely

Product parameters

Product Specifications | ||||

Do not | thing | data | ||

1 | Feeding system: 1) C-type mobile powerful clamp arm to control and operate the sheet metal panel. 2) Or you can choose to move the suction cup plate to control and operate the sheet metal panel. 3) The table has enough hard brushing and rolling stainless steel beads to protect the metal panel while machining | |||

2 | Bending length | 2500mm | ||

3 | Maximum bending height | 110mm | ||

4 | Minimum bending height | 6mm | ||

5 | minute. Four-side bend inner diameter | 320*320mm | ||

6 | Minimum unilateral bending inner diameter | 170mm | ||

7 | Minimum bending arc radius | 2.4mm | ||

8 | Minimum continuous bending speed | 0.4/s | ||

10 | Axle controllable | 10 sets | ||

11 | maximum feed rate | 120m/min | ||

12 | Equipment size | 5800*3000*2500mm | ||

13 | equipment weight | 22 tons | ||

14 | total power | 50kW | ||

15 | average power | 4kW | ||

The main function

The main function:

1. The four sides are bent;

2. Unilateral bending;

3. Continuous up and down bending, no need to replace the bending blade.

4. The curved edge of the curb can be bent flexibly at 0-90 degrees;

5. Automatically form a square rectangular curb.

6. The edge of the panel is automatically tightened;

7. Automatically form a rectangular box with a side length of up to 100mm.

8. Automatically bend a variety of complex panels with various angles of combination.

2. Unilateral bending;

3. Continuous up and down bending, no need to replace the bending blade.

4. The curved edge of the curb can be bent flexibly at 0-90 degrees;

5. Automatically form a square rectangular curb.

6. The edge of the panel is automatically tightened;

7. Automatically form a rectangular box with a side length of up to 100mm.

8. Automatically bend a variety of complex panels with various angles of combination.

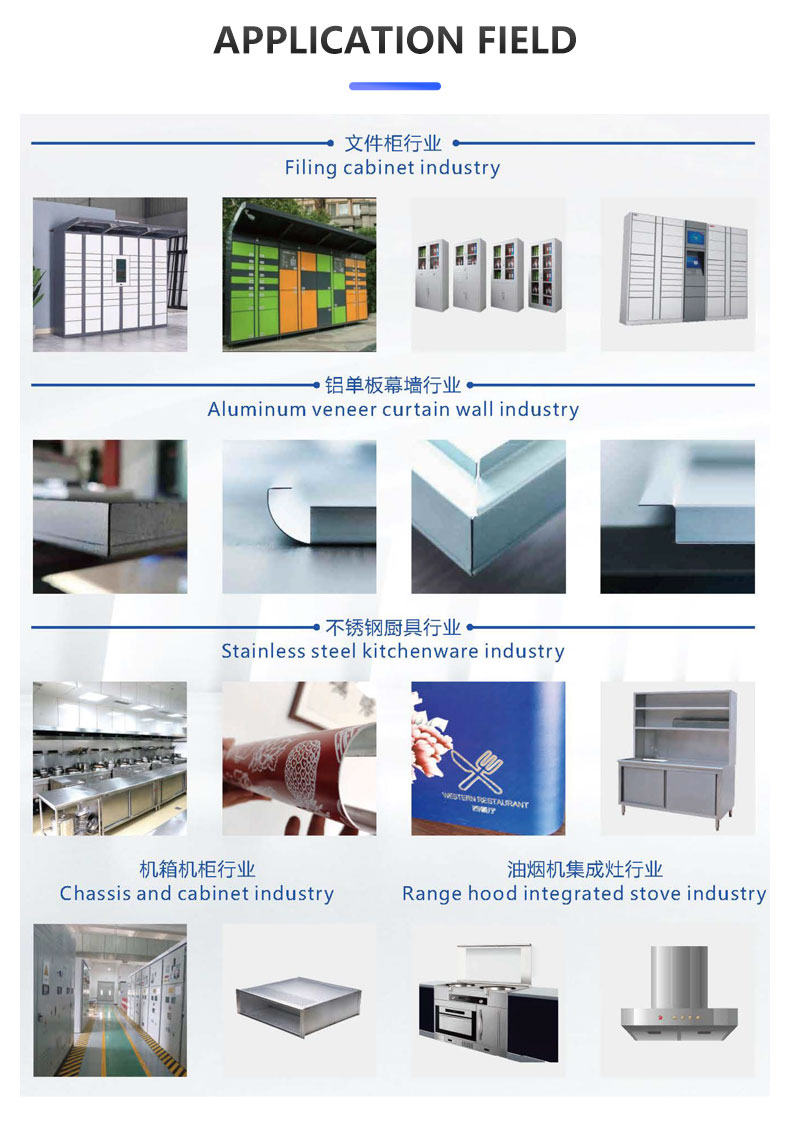

Application field

VIEW MORE

You may like

-

Easy-to-operate electric bending machine duct making machine for steel plate folding machine for steel plate folding processing machine

-

Cheap factory sale manual 1500 mm sheet metal bending machine sheet metal bending machine stainless steel plate bending machine

-

8.2m CNC hydraulic folding machine, slitting and folding machine

-

Electric Bending Machine Galvanized Sheet Bending Machine Sheet Metal Bending Machine Sheet Metal Bending Machine

-

Huaju Industrial W1.0x305A 12 Inch 20 Gauge Disc and Box Brake with Adjustable Removable Finger Folder

-

MYT brand W2.5X2540/W 2X3050 steel plate bending machine, sheet metal bending machine, manual bending machine

-

Stainless Steel Hydraulic Bending Machine Equipment Small CNC Bending Machine Sheet Bending Equipment

-

2.5*3000 stainless steel sheet metal electric hydraulic bending machine

-

Manual hand brake small sheet metal bending box and translation finger brake clip

-

Professional manufacture of cheap all-steel welded structure metal plate bending machine

Related Search

cnc used sheet metal bending machine for sale

customized sheet metal bending machine 8mm

250 ton sheet metal bending machine suppliers

sheet metal bending press bending machine

da52s sheet metal bending

manual sheet metal shearing machine

sheet metal shearing machine

sheet metal coating machine

china sheet metal welding machine

stainless steel bending machine sheet metal