5.5kw wood metal stone high speed water cooling spindle

-

Supplier: Jinan Dwin Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Matthew ma -

Price: $470.00 /piece -

Min. Order: 1 piece

| Delivery Details: | Spindle: 5 days after receiving your payment or deposit | Supply capacity: | 200 units per month |

| Material: | Stainless Steel/Wood/Stone | Chuck: | ER20 |

| Warranty: | 10 months | port: | Qingdao |

| place of origin; place of origin: | Shandong China | payment terms: | L/C,D/P,T/T,Western Union,MoneyGram,paypal |

| speed: | 24000 rpm | Voltage: | 220V/380V |

| model: | 5.5kw spindle | Cooling Type: | water cooling |

| application: | turning | Packaging Details: | 5.5kw spindle motor splint box, free of fumigation. |

| Power (kW): | 5.5kW | Max torque: | 0.8nm |

| Model: | 5.5kw spindle motor | drive: | motor |

| Running speed: | 24000r/min | brand: | Dwin CNC Machine Spindle |

| frequency: | 400-800HZ | diameter: | 80mm |

High-speed ER20 5.5kw water-cooled spindle

for woodmetalstone

Pre-Use Tip: Applies to All Spindles | |

1 | The electro-spindle and the inverter should be matched with each other. The specifications and parameter settings of the inverter should match the nominal parameters of the spindle. If the settings are incorrect, the spindle will be burned out. |

2 | Before using a water-cooled spindle, make sure that the cooling circulation system works normally, and it is forbidden to run without cooling. The cooling water volume is calculated at 1 liter/kW·min, the minimum cooling water flow rate is not less than 5 liters/min, and the cooling water pipe and the nozzle are connected reliably without leakage. |

3 | The coolant should be clean and free of grease, and the temperature should be between 5-30°C. When the ambient temperature is higher than 30℃, the cooling medium should be forced to cool. Precision lathes require coolant with a constant temperature of 20±2°C. |

4 | During storage and transportation of the spindle, the state of the high-speed grease inside the bearing changes. The user should run at low speed first, starting from the lowest speed of the spindle for 30 minutes, and then every 3000 rpm for 20 minutes; otherwise, abnormal noise, noise, heat and other phenomena will occur when the spindle is started directly at high speed, which will affect the bearing life. For long-term storage, the spindle should run at least once a week (low speed) for 15 to 30 minutes. |

5 | When installing the blade on the spindle, the collet, nut and inner taper hole should be cleaned so as not to affect the accuracy. The shank should be inserted into the chuck more than 15mm. |

6 | For daily machining, the spindle needs to be preheated, run for 15-20 minutes after reaching the machining speed, and then perform precision machining. It is best to stop the spindle for two hours a day to recover its mechanical fatigue and prolong its service life. |

7 | Do not knock on the spindle end cap. Do not hammer the collet and bit when removing the blade. During transportation, storage and use, especially the spindle end, there is no vibration or impact. |

8 | The spindle should run in the specified direction. |

9 | The main shaft should be installed and fixed according to the relevant drawings and instructions. |

10 | If using a water cooler, the temperature should be between 22-25°C. |

11 | The main shaft adopts steam lock, and the air source can be used only after passing through the oil-water separator and dry filter. The air pressure is 0.2-0.25MPa, and the filtration precision is 5μm, otherwise the bearing will be damaged. |

Model | strength | Outer diameter*length | collet | frequency | Voltage | speed |

Water-cooled spindle |

|

|

|

| ||

DW-62A | 800W | 62*200mm | ER11 | 400 Hz | 220V | 24000 rpm |

DW-65C | 800W | 65*205mm | ER11 | 400 Hz | 220V | 24000 rpm |

DW-80A | 1500W | 80*185mm | ER11 | 400 Hz | 220V | 24000 rpm |

DW-80B | 2200W | 80*205mm | ER20 | 400 Hz | 220V/380V | 24000 rpm |

DW-80C | 2200W | 80*215mm | ER20 | 400 Hz | 220V | 24000 rpm |

DW-80D | 1500W | 80*185mm | ER16 | 400 Hz | 220V | 24000 rpm |

DW-80E | 1500W | 80*215mm | ER11 | 400 Hz | 220V | 24000 rpm |

DW-80F | 1500W | 80*215mm | ER16 | 400 Hz | 220V | 24000 rpm |

DW-80G | 2200W | 80*215mm | ER16 | 400 Hz | 220V | 24000 rpm |

DW-80H | 2200W | 80*223mm | ER20 | 400 Hz | 220V | 24000 rpm |

DW-M80A | 1500W | 80*237mm | ER16 | 400 Hz | 220V | 24000 rpm |

DW-100A | 3000W | 100*252mm | ER20 | 400 Hz | 220V/380V | 24000 rpm |

DW-100B | 2200W | 100*228mm | ER20 | 400 Hz | 220V/380V | 24000 rpm |

DW-100C | 3000W | 100*271mm | ER20 | 400 Hz | 220V/380V | 24000 rpm |

DW-105A | 3500W | 105*271mm | ER20 | 400 Hz | 220V/380V | 24000 rpm |

DW-105B | 3500W | 105*252mm | ER20 | 400 Hz | 220V/380V | 24000 rpm |

DW-125A | 4500W | 125*320mm | ER25 | 330 Hz | 380V | 20000 rpm |

DW-125B | 4500W | 125*332mm | ER25 | 330 Hz | 380V | 20000 rpm |

DW-M85A | 2200W | 85*288mm | ER20 | 400 Hz | 380V | 24000 rpm |

DW-80J | 2200W | 80*230mm | ER20 | 400 Hz | 220V | 24000 rpm |

DW-80K | 2200W | 80*225mm | ER20 | 400 Hz | 220V | 24000 rpm |

DW-80L | 2200W | 80*232mm | ER20 | 400 Hz | 220V | 12000 rpm |

-

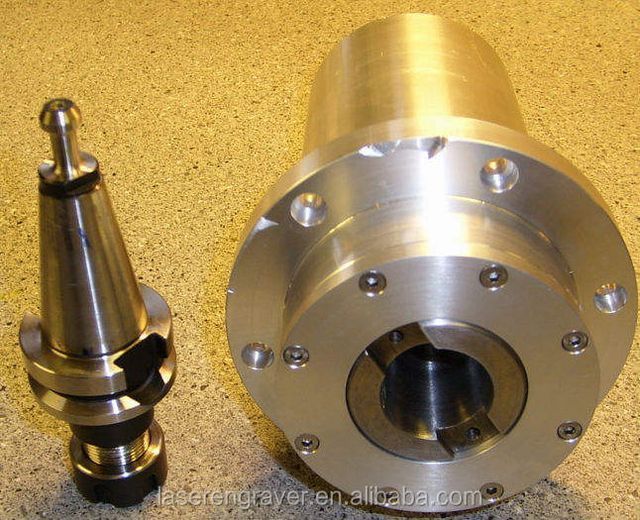

Pneumatic chuck lathe spindle automatic CNC three-jaw power head

-

BenFa stainless steel wire braiding spindle

-

High-power high-performance drilling machine air-cooled 220V 380V ISO30 ER32 400Hz 9KW 6KW 11KW ATC HSK automatic engraving spindle

-

DECI dental spindle motor for atc pcb milling machine engraving spindle

-

3.5KW BT30 Spindle CNC Engraving and Milling Metal ATC Spindle 3500W ER25 Tool Holder 220v/380v VFD CNC Parts

-

CNC BT30/40/50 Belt Machine Oil Cooler Machine Tool Spindle

-

Westwind Spindle PCB D1686-16 for GIGA machine

-

Inexpensive BT30 8000rpm OD90mm Belt Drive Spindle w/Driver, Motor, Pneumatic Cylinder

Other Products

-

$6400.00 / set

$6400.00 / set