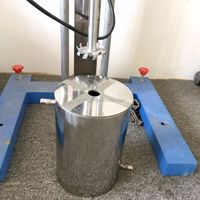

Fully automatic custom chemical stainless steel stirred tank reactor

-

Supplier: Zhejiang Shuangzi Intelligent Equipment Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Alice Wang -

Price: $7500.00 /set -

Min. Order: 1 set

Product details

| Warranty: | 1 year | Applicable industries: | Manufacturing Plants, Food and Beverage Plants |

| capacity: | 5000L, 5000L | After-sales service provided: | On-site installation, commissioning and training |

| Dimensions (L*W*H): | 2050*2050*4200mm | Voltage: | customized |

| brand: | sun | Marketing Type: | New Products 2020 |

| Supply capacity: | 600 sets per year | Health status: | new |

| Main selling point: | easy to operate | Material: | SUS304/SUS316L |

| Function: | reaction | Video external inspection: | if |

| strength: | 5.5kW | Showroom location: | U.S. |

| Packaging Preview: | usage: | Induction furnace reactor | |

| port: | Ningbo or Shanghai Port | Auto grade: | automatic |

| place of origin; place of origin: | Zhejiang, China | Core Components Warranty: | 1 year |

| Seal Type: | Machinery Seal | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Core components: | programmable logic controller | product name: | Stainless steel chemical reactor |

| Packaging Details: | Plywood shell or nude packaging | weight: | 5000 |

| Mechanical test report: | if | type: | Tank Reactor |

| heating method: | steam | Certification: | ASME certificate |

| Agitator shaft: | frame type |

Product Description

ThisFully automatic custom chemical stainless steel stirred tank reactorSuitable for chemical, pharmaceutical and other reactions. The reactor body can be provided with a structural honeycomb jacket, a pipe jacket or an integral jacket, and can also be heated and cooled. The inner surface is electrolytic mirror polished, the head head is processed by molding or spinning, and all the nozzles and dead corners are made of R-angle transition. All components are processed according to GMP standards. The styles of abrasives are anchor pin, round, frame and turbine. The rotary machine can use a cycloid gear reducer or a stepless reducer. The sealing device is a mechanical seal. Heating or cooling can be in a plug-in, half-pipe or serpentine configuration. Heating methods include steam heating, electric heating, heat transfer oil, etc., to meet the needs of various working environments such as acid, high temperature, wear, and corrosion. Acid resistance, high temperature resistance, wear resistance and corrosion resistance.

Application and structure:

ThisFully automatic custom chemical stainless steel stirred tank reactor It can be used as a distiller in the fields of medicine, chemical industry and bioengineering. The equipment is mainly composed of a cylinder body, an integral jacket and an outer packaging layer, and the insulation material is between the outer packaging layer and the jacket. It has a stirrer on top of the reactor.

Parameters/Models | LP300 | LP400 | LP500 | LP600 | LP1000 | LP2000 | LP3000 | LP5000 | LP10000 | ||||||||

Capacity (L) | 300 | 400 | 500 | 600 | 1000 | 2000 | 3000 | 5000 | 10000 | ||||||||

Working pressure (inner layer) | ≦0.6Mpa | ||||||||||||||||

Working pressure (jacket layer) | ≦0.8Mpa | ||||||||||||||||

Motor power (kw) | 1.1 | 1.5 | 2.2 | 2.2 | 3 | 3 | 3 | 5.5 | 7.5 | ||||||||

agitator speed | 0-200r/min | ||||||||||||||||

aspect | 900* 2200 | 1000*2200 | 1150*2400 | 1150*2500 | 1400* 2700 | 1580* 3000 | 1580* 3300 | 2050* 4200 | 2500* 5000 | ||||||||

heat exchange area | 2 | 2.4 | 2.7 | 3.1 | 4.5 | 7.5 | 7.5 | 10.4 | 20.2 | ||||||||

detailed image

VIEW MORE

You may like

-

Laboratory bioreactor filtration crystallization single and double layer 20L 10L 5L 50L 100L 200L jacketed glass reactor

-

Hot sale new stainless steel industrial chemical decarboxylation reactor

-

Laboratory 20L Chemical Reactor Stainless Steel Reactor

-

500ml catalyst test equipment chemical pressure reactor

-

Reasonable price epoxy resin reactor production line

-

High-quality AC reactor 11kw 30A RACL 2%-30/11 three-phase AC line reactor

-

Bromine production line

-

Plant Direct Methanol Synthesis Reactor System with Insulation Function

-

Benchtop desktop small glass laboratory 5l 10l microbiology photo plant cell bacterial fermentation fermenter fermenter bioreactor

-

SS316 Jacketed container for laboratory dispensing mixing

Related Search

stainless steel agitated tank

stainless steel mixing tanks

stainless steel mixing tank

stainless steel water tank

stainless steel fuel tank

stainless steel water tank welding machinery

stainless steel milk tank

4 frame automatic honey extractor stainless steel

stainless steel alcohol storage tanks

stainless steel agitation leaching tank