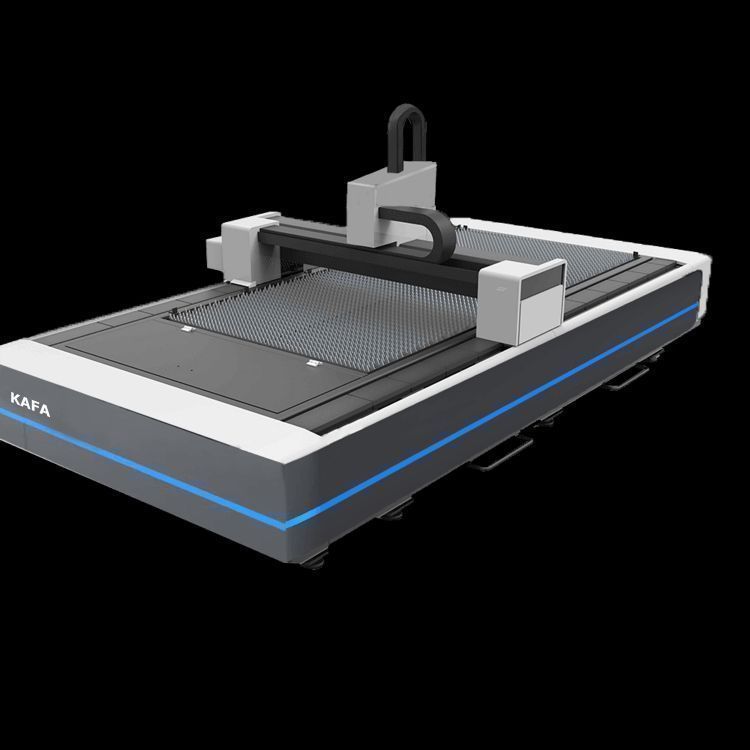

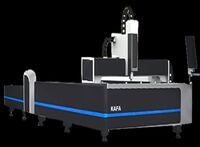

Fiber Laser Sheet Cutting Machine G Series

-

Supplier: Shanghai KAFA Technology Co., Ltd. -

Region: Shanghai, China -

Contact: Mr mr. meng -

Price: $20000.00 / >=5 sets -

Min. Order: 5 sets

Product details

Laser Cutter Equipment Main Configuration:

| Name | Origin and Manufacturer name |

| Special laser cutting head (auto focus) | RAYTOOLS |

| Cutting machine bed (steel plate welding) | Self-produced |

| Beam | Integrated Cast Aluminum |

| Guide | Taiwan HIWIN |

| Reducer | Japanese Ximpo |

| Gear, rack | Taiwan K.H/Germany Herion |

| Servo motor and driver | Japan Panasonic/YASKWA |

| Control Cabinet | Self-Produced |

| Low-voltage electrical appliances | Chint/France Schneider |

| Origin, limit switch | Swiss Carole |

| Cable | Flexible Shielded cable |

| Transformer | Shenzhen Xinbei Ocean |

| IPC | Taiwan Advantech |

| CNC system (including control software, height controller) | Cyp Cut |

| Oil Road | Electric oil pump |

| Gas circuit (proportional valve) | NNT |

| Chiller | Han Li |

Active Anti-Collision Function laser heads

Main Technical Parameters of Fiber Laser Cutting Machine

Device Model KAFA G Series

Laser Cutter Type Fiber-optic laser

CNC laser Cutter Wavelength 1064nm Rated output power 2000W Beam quality <0.373mrad X axis travel 3020mm

Y axis travel 1520mm Z axis travel 100mm Effective Cutting Range 3000*1500m

Workbench axial positioning accuracy <+0.05mm/m Worktable repeat positioning accuracy <+0.02mm/m Maximum empty speed 60m/min Workbench Maximum load 200KG Phase 3 Power supply rated voltage 380

Frequency 50Hz Total power protection level IP54 Expert High Speed Cutting Analysis- Carbon Steel Oxygen Fast Cutting (COF)

- Carbon Steel Economic Fast Cutting (CEF)

- Low Nitrogen Pressure Fast Cutting (LNF)

- Matched with High-End CNC System to assure precision control

Stretched Aluminum Beam

Tenon-and-Mortise Joint infra-structure

Cutting Metal Performance Table:

| Material | Thickness(mm) | Speed(m/min) | Power(W) | Auxiliary Gas |

| Stainless Steel | 1 2 3 4 5 6 8 1 2 3 4 5 6 8 | 35 10 6.5 4 2.4 1.6 0.9 30 9 6 3.2 2 1.2 0.6 | 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 | Air Air Air Air Air Air Air N2 N2 N2 N2 N2 N2 N2 |

| Carbon Steel | 1 2 3 3 4 4 5 6 8 10 12 14 16 | 9 4.2 3.8 3 3.3 2.8 2.6 1.8 1.3 1.1 1 0.9 0.8 | 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 | O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 O2 |

| Brass | 1 2 3 4 5 | 25 7.5 3.5 1.8 0.8 | 2000 2000 2000 2000 2000 | N2 N2 N2 N2 N2 |

| Aluminum | 1 2 3 4 5 6 8 1 2 3 4 5 6 | 30 8 4 2.5 2 1 0.6 30 9 3.2 2 1.4 0.8 | 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000 | N2 N2 N2 N2 N2 N2 N2 Air Air Air Air Air Air |

| Copper | 1 2 | 12 4 | 2000 2000 | O2 O2 |

| Galvanized Sheet | 1 2 3 | 25 9 4.5 | 2000 2000 2000 | N2 N2 N2 |

Working Process & Sample

VIEW MORE

You may like

-

Metal and non-metal dual-purpose fiber laser cutting machine VLF1530 fiber laser cutting machine

-

Voiern 20w 30w 50w 3d fiber laser engraving machine EZCAD JPT RAYCUS dual red dot fiber laser metal marking machine

-

High quality 6090 laser cutting machine 100w Ruida m2 wood laser cutting machine co2 laser

-

SCULPFUN S6 30W laser engraving machine wood acrylic laser engraving machine cutting high precision 410x420mm engraving area all metal

-

Lefeng Customized Wholesale Butterfly Pearl Letter Initial Stainless Steel Gold Zircon Heart Shape Star Moon Necklace Jewelry for Women

-

80w 100w 150w 200w 300w laser cutting board acrylic wood 6090 laser cnc engraving machine cortadora 1390 co2 laser cutting machine

-

Startnow S-37/S185LDF Small Multilingual Fiber Optic Fusion Splicer For Core Alignment Fusion Splicer Automatic Fusion Splicer

-

Hot Sale Best Quality Metal Laser Cutting Machine 12000mm*2500mm Aluminum Cnc Fiber Stainless Steel Laser Cutting Machine

-

Tube laser cutting machine KAFA-T Series

-

Metal sheet & tube laser cutting machines GEC-T Series

Other Products

-

-

$15000.00 / set

$15000.00 / set -

$35000.00 / set

$35000.00 / set -

$33000.00 / set

$33000.00 / set -

$28000.00 / set

$28000.00 / set -

$30000.00 / unit

$30000.00 / unit -

$24000.00 / unit

$24000.00 / unit -

-

-

$8000.00 / set

$8000.00 / set

Related Search

20w fiber laser scriber cutting machine

fiber lasers source marking machine

shandong laser cutter cutting machine

portable fiber laser marking metal machine sale

voyager cnc plasma metal sheet cutting machines

q11 sheet cutting machine

metal sheet cutting machin

stainless steel sheet cutting machine

6040 laser engraving cutting machine

cotton fiber fabric rag cutting machine