LXSHOW Hand-held 1500w 1000w 2KW Laser Welding Machine Factory Price

-

Supplier: Jinan Lxshow Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms Linda LXSHOW -

Price: $7100.00 / 1 - 1 sets

$7000.00 / 2 - 2 sets

$6700.00 / >=3 sets -

Min. Order: 1 set

Product details

| payment terms: | L/C,D/P,D/A,T/T | Mechanical test report: | if |

| Beam Quality: | 1.1 | Core components: | motor, gear |

| Packaging Details: | Standard plywood case | Laser source: | IPG Raycus Max JPT |

| aspect: | 137*80*115cm | Laser head brand: | Max/Rex |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies | Laser frequency: | 50Hz-5KHz |

| cooling method: | water or air | Adjustable power range: | 5-95% |

| brand: | Group exhibition | Video external inspection: | if |

| maximum. Output Power: | 1000w | Center wavelength: | 1070+-5nm |

| Output power stability: | <2% | wavelength: | 5/10/15m (optional) |

| Marketing Type: | New Products 2021 | Main selling point: | high productivity |

| Application materials: | metal stainless steel aluminum | Core Components Warranty: | 2 years |

| Laser source brand: | Rex | Laser power: | 1000 watts 1500 watts 2000 watts |

| usage: | metal welding | Health status: | new |

| Weight (kg): | 280kg | Warranty: | 2 years |

| Welding materials: | Metal Material | place of origin; place of origin: | Shandong China |

Product Description

Outlook supports customization!

You can also choose other models, and you can change the color and logo

Please click below to see the working effect

Choose the right configuration for your material

application

Laser welding is a new type of welding method, which is widely used in the automobile industry, metal processing industry, ship and aircraft manufacturing, furniture and kitchenware processing, electronic product processing, metal parts maintenance and other precision processing industries. Welding of thin-walled materials and precision parts. Spot welding, butt welding, lap welding and sealing welding can be realized. Laser welding machine for titanium alloys, galvanized sheets, aluminum, copper for precise welding

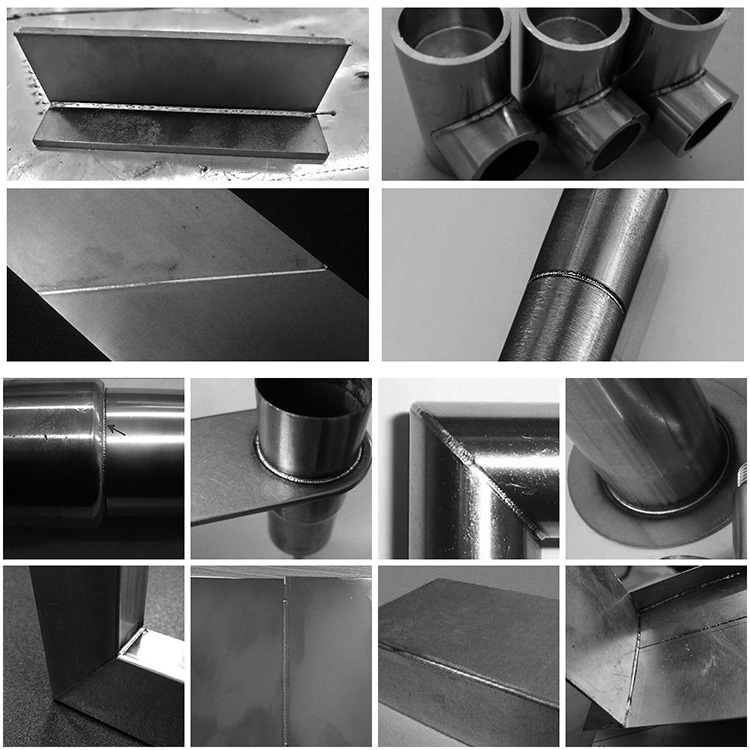

Right Angle Welding Sample

Tube arcwelding

irregular seam welding

Advantages of Laser Welding

1. Some other components that are easily damaged or cracked during soldering can be soldered non-contact, without causing mechanical stress to the object to be soldered The area is heated locally, and other non-welding areas are not affected by heat 4. The welding time is short, the efficiency is high, the solder joints will not form a thick intermetallic compound layer, and the quality is reliable 5. High maintainability. Traditional electric soldering iron welding requires regular replacement of the soldering iron tip, while laser welding requires few replacement parts, which can reduce maintenance costs

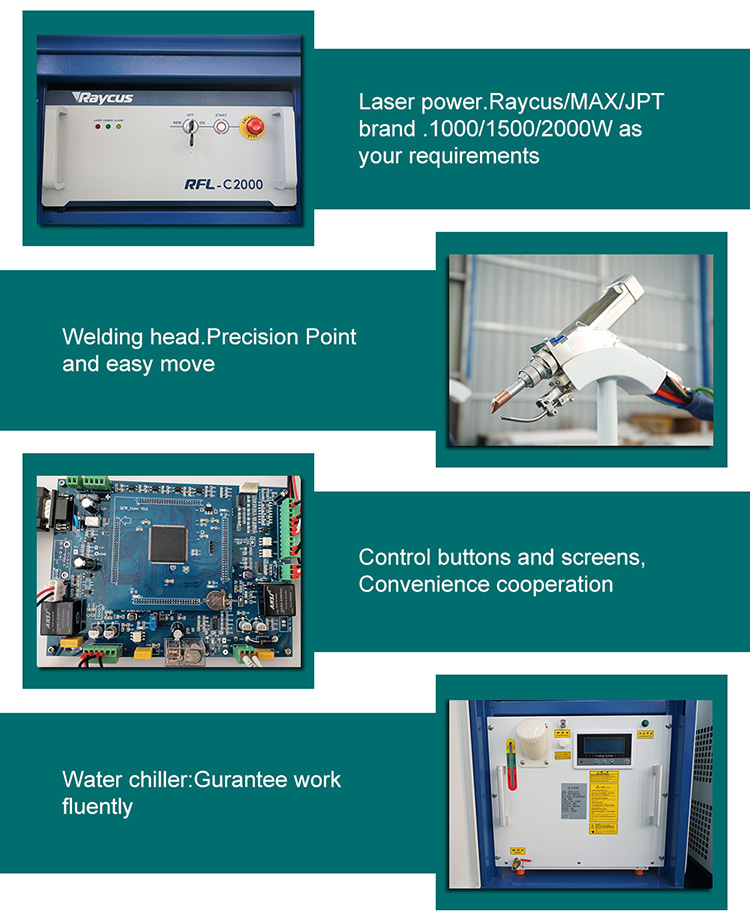

detailed picture

Product parameters

Model | LXW-1000/1500/2000W |

Laser power | 1000/1500/2000W |

Center wavelength | 1070+-5nm |

Laser frequency | 50Hz-5KHz |

Operating mode | continuously |

electricity demand | AC220V |

Output fiber length | 5/10/15m (optional) |

cooling method | water cooling |

aspect | 1150*760*1370mm |

weight | 275kg (approx.) |

Cooling water temperature | 5-45℃ |

Average power consumption | 2500/2800/3500/4000W |

Laser energy stability | <2% |

Air humidity | 10-90% |

VIEW MORE

You may like

-

New 4 in 1 handheld 700W 1500W 2000W laser welding machine with air cooling Raycus laser source gear core components

-

IPG LightWELD 1500XC Mini Air Cooled Handheld Fiber Laser Welding Machine

-

2023 New 1000W 2000W 3000W Small Handheld Metal Welding Laser Machine

-

Kirin V10 handheld fiber laser welding spare parts soldering iron welding machine welding head 2000w double swing

-

Hot sale 1000w 1500w 2000w handheld laser welding machine laser welding machine price portable laser welding machine

-

Cutting+welding+cleaning machine 1500w fiber laser welding system 3 in 1 metal welding machine

-

Laser Welding Machine 3000W Twin Wire Wider Weld Seam Stronger Cladding Surfacing Fast Welding Laser Machine 8mm Steel Fully Welded Once

-

Yag Spot Laser Welding Machine 100W 200 Watts Portable Jewelry Welding Machine

-

Boom Type High Speed Metal Laser Mold Welding System Laser Welding Machine

-

Handheld Laser Welding Machine China manufacture

Other Products

-

$3000.00 / set

$3000.00 / set