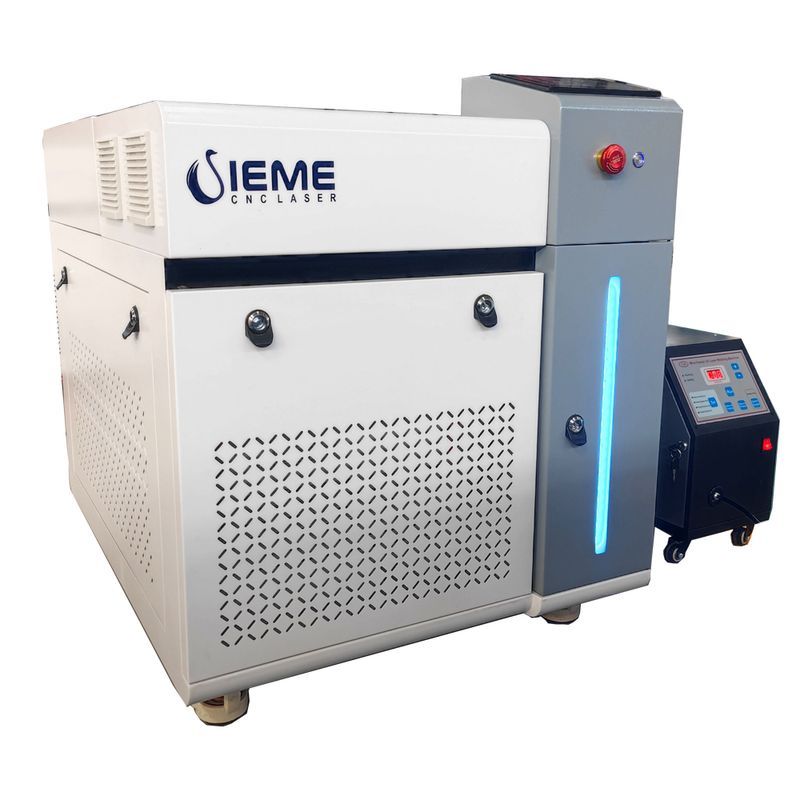

Handheld Laser Welding Machine China manufacture

-

Supplier: Jinan Sieme CNC Equipment Co.,Ltd -

Region: China -

Contact: Mr Caroline Zhang -

Price: $7800.00 /piece -

Min. Order: 1 piece

- Click to check laser machine working video

- Laser Type :SIEME Laser (Continuous Wave Laser)

- Laser Source Power : 1000W/1500W/2000W/3000W

- The laser wave length : 1070nm±5nm

- Welding thickness : 0.5-5mm

- Working voltage : 1 PHASE, 220V 50/60Hz

- Cooling Method : Water Cooling

- Price Range: $4500.00 to $11000.00

- Application : Laser welding machine is widely used in the complicated and irregular welding processes of cabinets and kitchens,stair lifts,shelves,ovens,stainless steel doors and windows guardrails,distribution boxes,stainless steel furniture,metal sheet metal and other industries.

Advantages of Handheld Laser Welding Machine

Improve process defects: Hand-held laser welding can improve welding defects such as undercut, under-welding, dense pores and cracks in the traditional welding process.

Good welding effect: fast welding speed, smooth and beautiful weld after welding. When welding, the heat affected area is small, which will not cause work deformation, blackening, and trace problems on the back. Moreover, the welding depth is large, the welding is firm, and the melting is sufficient.

Cost-saving: good welding effect reduces subsequent grinding process, saving time and cost (2-10 times faster than traditional welding, a machine can save at least 2 welders a year and fewer consumables). Fewer consumables, long life and low equipment maintenance costs.

Simple operation: welding by hand, quick start, flexible and convenient, and longer welding distance.

High flexibility: suitable for all kinds of complex welds, easy to weld any part of the workpiece at any angle. Further, broaden the scope of application of laser welding.

Technical Parameter

Laser Welding, Cleaning and Cutting DetailsLaser Source Power 1000W/1500W/2000W/3000W Maximum Modulation Frequency 100KHz Cable length 10 m (customizable) Welding thickness 0.5-5mm Cooling method Water cooling Gas assist Nitrogen/Argon Visual positioning Red dot Machine dimension 87*56*105cm Working voltage 1 PHASE, 220V 50/60Hz Scan Width 0-6mm 1000W-Max. Welding Thickness Stainless Steel: 3mm; Iron: 3mm; Carbon Steel: 3mm; Brass: 3mm; Aluminum: 2mm: Galvanized Sheet: 3mm 1500W-Max. Welding Thickness Stainless Steel: 4mm; Iron: 4mm; Carbon Steel: 4mm; Brass: 4mm; Aluminum: 3mm: Galvanized Sheet: 4mm 2000W-Max. Welding Thickness Stainless Steel: 5mm; Iron: 5mm; Carbon Steel: 5mm; Brass: 5mm; Aluminum: 4mm: Galvanized Sheet: 5mm - 1.Welding

- 2.Cleaning

- Handheld Laser Welding Machine application

- Laser welding machine can be used for various metals, such as titanium welder, nickel, tin, zinc, copper, aluminum, chromium, bismuth, gold welder, silver, etc., as well as welding of the same materials as steel and Kovar.Laser welder laso used in various dissimilar metals, such as copper nickel, nickel titanium, copper titanium, brass copper, low carbon steel copper.

Many industries and sectors rely on laser welder. The most common ones include:

- Automobile industry

- Aerospace industry

- Assembly manufacturing industry

- Engineering and IT department

- Construction industry

- Sheet metal, chassis and water tank

- Various hardware lights

- Door and window frame

- Kitchen and washbasin hardware

- Billboards, advertisements, etc.

Is laser welding machine strong

The main purpose of laser welding machine is to make a connection of sufficient strength between the two sides of the welding materials. The laser welder strength has a great relationship with the laser welding equipment power and the work speed as well as the welding material.

- Under the same laser welding machine power, the welding speed directly affects the welder strength. The faster the laser welders peed, the narrower the weld seam, then the welding cannot be formed quickly. In other words, the faster the laser welder speed, the weaker the laser welding strength. Besides, the faster the welding speed, the shallower the penetration, so when welding thin plates or materials with better weldability, high-speed welding can be used, but it’s better to use low-speed when laser welding machine work on thick plates or difficult-to-weld materials.

- When the laser welding machine speed remains the same, the higher the laser power, the better laser welder intensity. That is to say, when the laser welding machine’s power is increased from 1000W to 2000W, the penetration depth will increase and the laser welding strength will also increase.

Our Changtai company is currently doing strength experiments on handheld welding machines

1) 1000W laser welding machine can weld stainless steel within 3 mm.

2) 1500W laser welding machine can weld stainless steel within 5 mm.

3) 2000W laser welding machine can weld stainless steel within 8 mm.

If there is a relatively large weld (greater than 0.3mm) between the two materials, then we would recommend the customer to use an automatic wire feeder.

In addition, the laser welder strength is also affected by the welding material, no matter there is gas assist during welding or not. Different materials have different absorption of laser light. The surface state of the material (the degree of smoothness) has an important influence on the absorption rate of the laser; The shielding gas is assisted to prevent the workpiece from being oxidized during welding, protect the focusing lens, and dissipate the plasma shield generated during high-power laser welding. Then the welding strength will be further improved.

In summary, there is a suitable welding speed range for a certain laser power and a certain thickness of a specific material. When the relevant conditions are met, the laser welding machine strength is naturally very strong. It is definitely larger than the traditional welding process on the market.

-

New 4 in 1 handheld 700W 1500W 2000W laser welding machine with air cooling Raycus laser source gear core components

-

IPG LightWELD 1500XC Mini Air Cooled Handheld Fiber Laser Welding Machine

-

2023 New 1000W 2000W 3000W Small Handheld Metal Welding Laser Machine

-

Kirin V10 handheld fiber laser welding spare parts soldering iron welding machine welding head 2000w double swing

-

Hot sale 1000w 1500w 2000w handheld laser welding machine laser welding machine price portable laser welding machine

-

Cutting+welding+cleaning machine 1500w fiber laser welding system 3 in 1 metal welding machine

-

Laser Welding Machine 3000W Twin Wire Wider Weld Seam Stronger Cladding Surfacing Fast Welding Laser Machine 8mm Steel Fully Welded Once

-

Yag Spot Laser Welding Machine 100W 200 Watts Portable Jewelry Welding Machine

-

Boom Type High Speed Metal Laser Mold Welding System Laser Welding Machine

-

200w gold and silver YAG fiber laser welding machine desktop jewelry laser welding machine