Deguang high speed auto register rotogravure printing machine

-

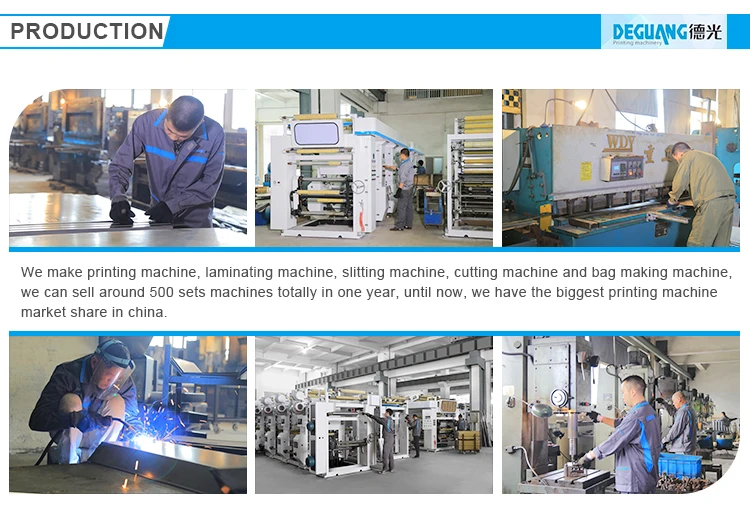

Supplier: Zhejiang Deguang Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Kelvin Miao -

Price: $60000.00 / 1 - 1 sets

$55000.00 / >=2 sets -

Min. Order: 1 set

| Packaging Detail: | Damp Proof Packing; | Supply Ability: | 10 Sets per Month; |

| Warranty: | 1 Year; | Voltage: | 380v/50hz; |

| Payment Terms: | L/C,Western Union,T/T,MoneyGram; | Automatic Grade: | Automatic; |

| Warranty of core components: | 1 Year; | Function1: | Computerized Color Register Rotogravure Press; |

| Plate Type: | Gravure Printing Cyliner; | Dimensions(L*W*H): | 12000x3800x2800mm; |

| Color & Page: | Multicolor; | Video outgoing-inspection: | Provided; |

| Machinery Test Report: | Provided; | Printing speed: | 150m/min; |

| Print width: | 800mm, 1100mm; | Condition: | New; |

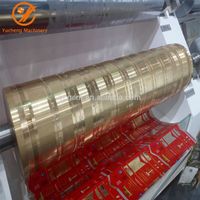

| Place of Origin: | Zhejiang, China; | Print Material: | BOPP .PET.PVC.PE.Aluminum Foil; |

| Drying method: | Electric Heating; | Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory; |

| Name: | Roto Gravure Printing Machine; | Key Selling Points: | Automatic; |

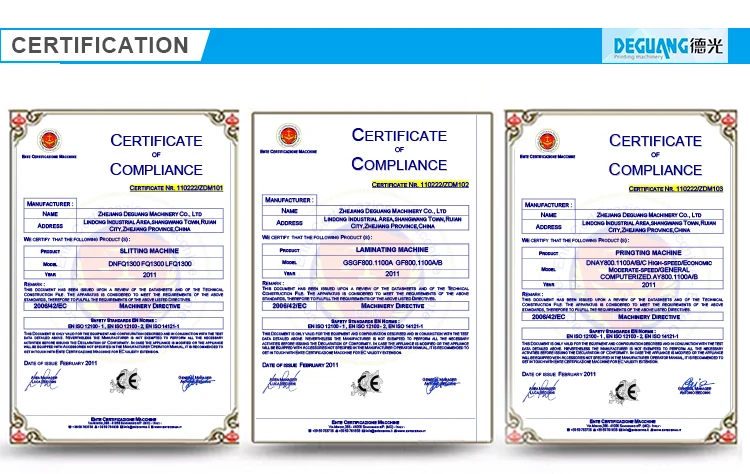

| Usage: | Label Printer,Paper Printer,Other; | Certification: | CE/ SGS; |

| Weight: | 18000kg(6 colors); | Local Service Location: | Turkey,Viet Nam,Philippines,Pakistan,India,Malaysia,South Korea,Chile,Bangladesh; |

| Port: | Ningbo or Shanghai; | Showroom Location: | Viet Nam,Pakistan,India,Morocco,Kenya,UAE,Colombia,Algeria,Kazakhstan; |

| Marketing Type: | Ordinary Product; | Brand Name: | DEGUANG; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Type: | Rotogravure Printing Machine; | Printing colors: | Multi Color; |

| Product name: | Rotogravure Printing Press; | Core Components: | PLC; |

Auto register rotogravure printing machine

Technical parameter (Based on 6 colors)

|

Model |

DNAY800C |

DNAY1100C |

|

Printing width |

800mm |

1100mm |

|

Material width |

830mm |

1130mm |

|

Printing cylinder diameter |

φ100-350mm |

φ100-350mm |

|

Printing speed |

150m/min |

150m/min |

|

Unwind diameter |

600mm |

600mm |

|

Rewind diameter |

600mm |

600mm |

|

Register accuracy |

±0.1mm |

±0.1mm |

|

Total power |

140KW |

150KW |

|

Weight |

18000KG |

19000KG |

|

Dimension |

12000*3800*2800mm |

12000*4100*2800mm |

|

Video link |

https://www.youtube.com/watch?v=ZCPMjVlPg1A |

|

Feature:

1. 7 servo motor controlling system, it can make tension close loop control, so we can make the material waste to the least, during one year’s running, you can save huge cost.

2. Unwind double station turret with air shaft, two servo motor control, automatic splicing and cutting with non stop.

3. Rewind double station turret with air shaft, two servo motor control, auto splicing and cutting with nonstop.

4. Independent chassis without connection, the bolt will be installed into the ground which make machine more stable during high speed running.

5. New design enclosed type doctor blade, pneumatic move, it can remove extra ink completely from the printing cylinder, so that the printing picture will be more clear and shinning

6. Shaftless pneumatic printing cylinder installation which can save much time

7. Ink is circulated automatically by ink pump

8. Special ink plate design make ink touch printing cylinder completely and better for ink circulate.

9. Automatic computer register with video inspection.

10. It equipped with double long register which has longer moving distance, so it has bigger range of registration adjustment to make registration accurate.

11. Independent drying and suction exhausting system, air circulated, max recycled rate 50%, waste air eliminating tunnel. External blower increase the air amount for a better heating.

12. Unwind 2 floating roller, rewind 2 floating roller to micro adjust the tension during machine running

13. Oven is pneumatic open and close which is convenient for material guiding.

14. Assisted oven installed on the last printing unit, when last color cover the whole cylinder, it can ensure to dry the material completely.

15.Turning bar can be installed to do reverse printing for PE tube material

16. Water cooling roller is installed on the top of each printing unit to do the cooling after heating

17. Ultrasonic EPC device can be installed on the top of unwind part especially for bad quality material

-

Rotogravure printing machine 2 4 6 colors biodegradable plastic film

-

Wallpaper production equipment Non-woven wallpaper gravure printing line Cloth wallpaper embossing line

-

Cigarette paper engraving machine

-

Second-hand 8-color drop-roll gravure printing machine

-

Flexo ink proofer for gravure and flexo printing factories

-

Gravure printing machine 9 color cigarette case tipping paper printing machine

-

Rotogravure printing machine 8 colors price printing machine plastic rotogravure printing machine

-

mini rotogravure printing machine

-

Two-color gravure printing machine ASY-2800

-

LDPE printer printing PE rotogravure with 6 colors gravure printing machine shop bag with good quality