DN100-150 Vacuum Insulated Pneumatic Shut off Valve which controls Liquid Hydrogen in Vacuum Pipe

-

Supplier: Chengdu Holy Cryogenic Equipment Co., Ltd. -

Region: Sichuan, China -

Price: $1524.00 / 1 - 9 sets

$1454.00 / 10 - 19 sets

$1385.00 / >=20 sets -

Min. Order: 1 set

Product details

| Machinery Test Report: | Provided; | Core Components: | Cryogenic Valve; |

| Place of Origin: | Sichuan, China; | Marketing Type: | Ordinary Product; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company,Other; | Supply Ability: | 40 Meters per Quarter; |

| Key Selling Points: | Energy saving; | Dimension(L*W*H): | 500x200x200mm; |

| After Warranty Service: | Video technical support,Online support,Spare parts; | Package Preview: | ; |

| Application: | Industrial; | Function: | Piping Controlling; |

| Hoisting Height: | 200 m; | Transmission Length: | 10 km; |

| Video outgoing-inspection: | Provided; | Condition: | New; |

| After-sales Service Provided: | Video technical support,Online support; | Showroom Location: | None; |

| Port: | Shanghai Port, Qingdao Port, Shenzhen Port, Chongqing Port; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Weight: | 30kg; | Material: | Stainless Steel; |

| Warranty of core components: | 1 Year; | Warranty: | 1 Year; |

| Type: | valve; | Local Service Location: | None; |

| Brand Name: | HL; | Packaging Detail: | Metal Shelf without wood. Vacuum Insulated Pipe (VIP) shall be cleaned before packaging and kept the nitrogen filling state in the inner pipe. VIP is wrapped up by two-layer packing materials. The first layer, the VIP is completely sealed with a film to prevent moisture, and the second layer is completely wrapped with packing cloth, which mainly protects against dust and scratches. The packaged VIPs will be placed in the metal shelf like the picture shows.; |

Introduction

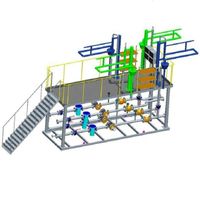

Vacuum Insulated Piping Controlled by The Vacuum Insulated Valve (VIV) Series: Including VI (Pneumatic) Shut-off Valve, VI Check Valve, VI Pressure and Flow Regulating Valve etc. Various types of VIV can be modular combined to control the VI Piping as required.

VIV is integrated with VI Pipe prefabrication in manufacturer, without on-site Insulated treatment. The seal unit of VIV can be replaced easily.

HL accepts the cryogenic valve brand designated by customers, and then makes vacuum insulated valves by HL. Some brands and models of valves may not be able to be made into vacuum insulated valves.

Specification

The Vacuum Insulated Pneumatic Shut-off Valve, namely Vacuum Jacketed Pneumatic Shut-off Valve, is one of the common series of VI Valve. Pneumatically controlled Vacuum Insulated Shut-off Valve to control the opening and closing of main and branch pipelines.

The VI Pneumatic Shut-off Valve can be connected with PLC system to achieve more automatic control functions.

Model | HLVSP000 Series |

Name | Vacuum Insulated Pneumatic Shut-off Valve |

Nominal Diameter | DN15 ~ DN150 (1/2" ~ 6") |

Design Pressure | ≤40bar (4.0MPa) |

Design Temperature | -196℃~ 60℃ (LH2 & LHe:-270℃ ~ 60℃) |

Cylinder Pressure | 3bar ~ 14bar (0.3 ~ 1.4MPa) |

Medium | LN2, LOX, LAr, LHe, LH2, LNG |

Material | Stainless Steel 304 |

On-site Installation | No, connect to air source. |

On-site Insulated Treatment | No |

HLVS000 Series, 000 represents the nominal diameter, such as 025 is DN25 1" and 100 is DN100 4".

Product packaging

About The Production

About the Scope of Supply

* Vacuum Insulated/Jacketed Pipe

* Vacuum Insulated/Jacketed Flexible Hose

* Phase Separator/Vapor Vent

* Vacuum Insulated (Pneumatic) Shut-off Valve

* Vacuum Insulated Check Valve

* Vacuum Insulated Regulating Valve

* Vacuum Insulated Connector for Cold Box & Container

* MBE Liquid Nitrogen Cooling System

* Other cryogenic support equipment related to VI piping, including but not limited to, such as safety relief valve

(group),liquid level gauge, thermometer, pressure gauge, vacuum gauge, electric control box and so on.

* Vacuum Insulated/Jacketed Flexible Hose

* Phase Separator/Vapor Vent

* Vacuum Insulated (Pneumatic) Shut-off Valve

* Vacuum Insulated Check Valve

* Vacuum Insulated Regulating Valve

* Vacuum Insulated Connector for Cold Box & Container

* MBE Liquid Nitrogen Cooling System

* Other cryogenic support equipment related to VI piping, including but not limited to, such as safety relief valve

(group),liquid level gauge, thermometer, pressure gauge, vacuum gauge, electric control box and so on.

About the Application of VI Piping

*Air Separation Plant

*Electronic Engineering Industry

*Semiconductor and Chip

*Aerospace

*Automobile Engine and Electromotor

*Bio-pharmaceutical Industry

*Food & Beverage Industry

*Liquefied Natural Gas (LNG)

About Our Partnership

HL Cryogenic Equipment passed International Gases Companies’ (inc. Air Liquide, Linde, AP, Messer, BOC) on-site audit and became their qualified supplier. The International Gases Companies respectively authorized HL to produce with its standards for its projects. HL provided solutions and products to them in air separation plant and gas application projects.

About the Raw Materials

HL Cryogenic Equipment is a vacuum manufacturer. All raw materials are purchased from qualified suppliers. So, The raw materials can be specified standards and requirements by user. Usually, ASTM /ASME 300 Series Stainless Steel (Acid Pickling, Mechanical Polishing, Bright Annealing and Electro Polishing) is selected.

FAQ

Q:About the Minimum Order.

A:There is no limited for minimum order.

Q: About the Manufacture Standard.

A:HL's Vacuum Insulated Pipe (VIP) is built to ASME B31.3 Pressure Piping code as the standard.

Q:About the Specification.

A:The size and design pressure of the inner pipe shall be according to the customer's requirements.The size of the outer pipe shall be according to the HL standard (or according to the customer's requirements).

VIEW MORE

You may like

-

50TPD solid sodium silicate glass production line chain conveyor

-

1.5 inch PP pneumatic double diaphragm glue pump

-

Hot sale signal alarm rail

-

Hot sale railway construction end connecting wire sheath switch jumper wire

-

truck for transporting CO2 liquid oxygen

-

Automatic skid-mounted bulk loading arm with loading control system

-

QVC Food Pneumatic Vacuum Conveyor

-

electric hydraulic marine loader marine unloading arm

-

Wholesale Price Stable Compost Belt Conveyor Equipment Made in China

-

ASME & CE DN10-150 Stainless Steel Low Temperature Vacuum Jacketed Braided Hose

Other Products

-

$150.00 / meter

$150.00 / meter -

$610.00 - $671.00 / set

$610.00 - $671.00 / set -

$300.00 - $320.00 / meter

$300.00 - $320.00 / meter -

$175.00 - $190.00 / meter

$175.00 - $190.00 / meter

Related Search

water valve shut off

pneumatic actuator for valves

automatic bucket full shut-off dehumidifier

auto shut off electric iron suppliers

auto shut off water tds meter price

pneumatic angle seat valve

5 3 solenoid valve way pneumatic air

electric on off water valve

switch on/off vacuum cleaner

vacuum ball valves