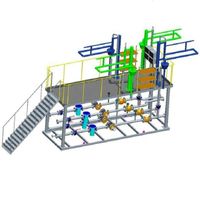

50TPD solid sodium silicate glass production line chain conveyor

-

Supplier: Shandong Water Glass Mechanical Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Cutter Ge -

Price: $6000.00 /set -

Min. Order: 1 set

| Local service locations: | not any | Health status: | new |

| Post-warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Supply capacity: | 10 sets per quarter |

| Main selling points: | competitive price | port: | Qingdao |

| brand: | GW | Package preview: | |

| Place of origin: | Shandong Province, China | weight: | Changing |

| Transmission length: | 0.20 kilometers | Mechanical test report: | if |

| Applicable industries: | manufacturing plant | Packaging details: | 20 whole boxes |

| Core component warranty: | 3 years | After-sales service provided: | Engineers can repair machinery overseas, on-site installation, commissioning and training, on-site maintenance and repair services, video technical support, online support |

| Warranty: | 1 year | Showroom location: | Vietnam, Indonesia, Russia, Nigeria, Malaysia |

| Certification: | ISO9001-2008 | Marketing type: | 2020 new products |

| Video outbound inspection: | if | Lift height: | 5 meters |

| payment terms: | Letter of credit, wire transfer | Dimensions (length*width*height): | custom made |

| Core components: | Engines, bearings, gearboxes, motors, pressure vessels, gears, pumps |

production details

The water glass chain conveyor is a very important water glass machinery in the water glass production line. The chain conveyor adopts a frame type frame and is arranged at an angle. The head and tail of the frame are respectively equipped with a pair of driving sprockets and a pair of driven sprockets. They are connected by chains with chain plates between them as material supports. There are cooling water pipes under the upper chain plate with small holes. A cooling water tank is installed at the bottom of the frame for cooling water supply.

Main ingredients

1 Transmission system: motor, reducer, sprocket, chain, bearing, etc.

2Support system: chain plate, spindle box, tailstock, intermediate frame bracket, etc.

3. Control system

4. Cooling system, etc.

5.Others

Commonly used specifications are 16 meters, 18 meters, 20 meters, 22 meters, 25 meters, or customized according to customer requirements, suitable for 20-120 tons/day delivery.

feature

1. The chain plate is used as the forming device. The high-temperature material liquid flows directly from the kiln to the chain plate. According to the shape of the plate hole, it can meet the requirements of various shapes of solid water glass blocks.

2. The cooling medium is water, but the material does not come into contact with water and will not hydrolyze or contain water.

3. The formed materials can be directly put into the silo for packaging or storage. Water glass bonding rarely occurs

4. The cooling water is circulating water, which has less pollution and consumption, saves water and electricity, has high product yield, and is a clean production process.

feature

1. Low loss: The product loss of water quenching method is more than 1%; while the product loss of chain conveyor can be as low as 0.01%.

2. Higher quality: the final product is not in direct contact with cooling water, which improves the purity of solid sodium silicate and avoids agglomeration.

3. Less waste of water resources and less pollution: The water quenching method will use a large amount of water, thus causing water pollution to the environment, and the PH value can be as high as more than 10; The cooling water is recycled at the bottom of the chain plate of the chain plate conveyor.

4. Better usability: The final product has a certain shape and uniformity, is easy to package, transport, and store, and is also very suitable for dissolution.

-

1.5 inch PP pneumatic double diaphragm glue pump

-

Hot sale signal alarm rail

-

Hot sale railway construction end connecting wire sheath switch jumper wire

-

truck for transporting CO2 liquid oxygen

-

Automatic skid-mounted bulk loading arm with loading control system

-

QVC Food Pneumatic Vacuum Conveyor

-

electric hydraulic marine loader marine unloading arm

-

Wholesale Price Stable Compost Belt Conveyor Equipment Made in China

-

ASME & CE DN10-150 Stainless Steel Low Temperature Vacuum Jacketed Braided Hose

-

JB series spice power screw feeder

Other Products

-

$5000.00 / set

$5000.00 / set -

$5000.00 / set

$5000.00 / set