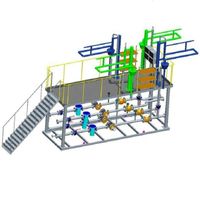

25M sodium silicate machine for sodium silicate production line

-

Supplier: Shandong Water Glass Mechanical Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Cutter Ge -

Price: $5000.00 /set -

Min. Order: 1 set

| Health status: | new | Packaging Preview: | |

| Transmission length: | 0.025 km | Local service location: | not any |

| payment terms: | L/C,D/A,D/P,T/T | Main selling point: | competitive price |

| Dimensions (L*W*H): | custom made | Warranty: | 1 year |

| Lifting height: | 5 meters | weight: | 100 tons |

| After Warranty Service: | Video technical support, online support, spare parts | Applicable industries: | manufacturing plant |

| Packaging Details: | 20 FCL | Supply capacity: | 5 sets per month |

| brand: | GW | place of origin; place of origin: | Shandong China |

| port: | Qingdao Port | Certification: | ISO9001-2008 |

| After-sales service provided: | Engineers can repair machinery overseas | Showroom location: | Egypt, Peru, Indonesia, India, Thailand, Nigeria, Malaysia |

feature

1. The chain plate forming machine is used as the forming device, and the high-temperature feed liquid flows directly from the kiln to the chain plate. According to the shape of the plate hole, it can meet the requirements of various shapes of solid water glass blocks.

2. The cooling medium is water, but the material is not in contact with water, and will not be hydrolyzed or contain water

3. The formed materials can directly enter the silo for packaging or storage. Sodium silicate bonding phenomenon rarely occurs

4. The cooling water is circulating water, with less pollution, less consumption, water saving and electricity saving, and high product yield, which is a clean production process.

feature

1. Less loss: the product loss of the water quenching method is more than 1%; while the product loss of the chain conveyor can be as low as 0.01%.

2. Higher quality: the final product is not in direct contact with cooling water, thus improving the purity of solid water glass and avoiding agglomeration

3. Less water waste and less pollution: the water quenching method consumes a lot of water, causing water pollution to the environment, and the pH value can be as high as 10 or more; and the cooling water is recycled at the bottom of the chain plate for chain conveyors.

4. Better use: The final product has a certain uniform shape, which is convenient for packaging, transportation and storage, and is very suitable for dissolution.

Production details

The chain plate conveyor is the sodium silicate machine of the sodium silicate production line. The machine adopts a frame-type rack and is arranged in an inclined manner. A pair of driving sprockets and a pair of driven sprockets are respectively installed at the head end and the tail end of the frame. They are connected by chains with chain plates between the chains as material supports. The cooling water pipes are respectively arranged under the upper chain plate, and there are small holes on the pipes. The cooling water tank is installed at the lower part of the frame for cooling water supply.

main ingredient

1 Transmission system: motor, reducer, sprocket, chain, bearing, etc.

2 Support system: chain plate, headstock, tailstock, middle frame, etc.

3. Control system

4. Cooling system, etc.

5. Others

Common specifications, 16 meters, 18 meters, 20 meters, 22 meters, 25 meters, or customized according to customer requirements, suitable for 20-120 tons / day delivery.

Q1. What kind of sodium silicate can the device dissolve?

A: This sodium silicate machine is specially used for solid sodium silicate lumps, but if it is sodium silicate granules, it is also a good choice.

Q2. What about delivery time?

A: 30-40 days after down payment

Q3. How to determine the length and width of the device?

A: You can tell us the production capacity of your sodium silicate furnace so that we can recommend the best choice to you

Q4. How do you ship the goods?

A: We usually ship one unit in 20'GP, if it's 2 units, you need 40'GP, however, we prefer to use an open top container because it's easier and safer to load and unload.

Q5. How do I place an equipment order?

A: First let us know your requirement or application.

Secondly, we quote according to your request or our suggestion.

Third, the customer confirms and places a deposit for the formal order.

Fourth, we arrange production.

Q6. Can the hole size be customized?

A: Yes, it can be customized.

Q7: Do you provide guarantee for the product?

A: Yes, we provide 1 year warranty for our products.

Q8: How about installment payment?

Usually we can give you detailed installation information, such as text, pictures or videos, if you want our engineers to help you install the sodium silicate machine, it's also ok, the installation cost will be discussed.

-

50TPD solid sodium silicate glass production line chain conveyor

-

1.5 inch PP pneumatic double diaphragm glue pump

-

Hot sale signal alarm rail

-

Hot sale railway construction end connecting wire sheath switch jumper wire

-

truck for transporting CO2 liquid oxygen

-

Automatic skid-mounted bulk loading arm with loading control system

-

QVC Food Pneumatic Vacuum Conveyor

-

electric hydraulic marine loader marine unloading arm

-

Wholesale Price Stable Compost Belt Conveyor Equipment Made in China

-

ASME & CE DN10-150 Stainless Steel Low Temperature Vacuum Jacketed Braided Hose

Other Products

-

$6000.00 / set

$6000.00 / set -

$5000.00 / set

$5000.00 / set