200 Mesh Barite Limestone Gypsum Calcite Grinding Mill Raymond Gypsum Mill Powder Making Milling Equipment In India

-

Supplier: Shanghai Zenith Mineral Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Carole Wu -

Price: $14800.00 / 1 - 1 sets

$14500.00 / >=2 sets -

Min. Order: 1 set

| Showroom Location: | Brazil,Peru,Saudi Arabia,Indonesia,India,Mexico,Russia,Thailand,Kenya,Chile,Colombia,Romania,South Africa,Kazakhstan; | Applicable Industries: | Building Material Shops,Construction works ,Energy & Mining; |

| Warranty: | 1 Year; | Dimension(L*W*H): | Grinding Mill; |

| Condition: | New; | Type: | Raymond Mill; |

| Brand Name: | ZENITH; | Video outgoing-inspection: | Provided; |

| Spare Parts Supply: | For Whole Year; | Local Service Location: | Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,India,Mexico,Russia,Thailand,Malaysia,Kenya,Chile,Colombia,Algeria,South Africa; |

| Marketing Type: | New Product 2020; | After-sale service: | For Whole Using Life; |

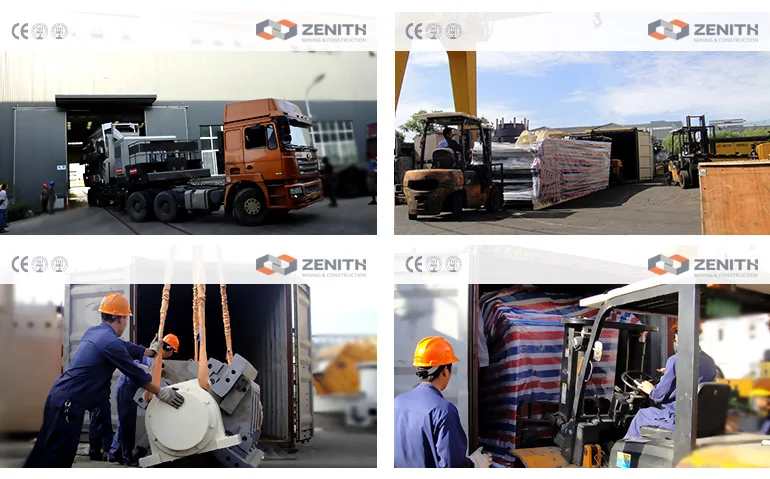

| Packaging Detail: | standard container of raymond gypsum mill in india; | After-sales Service Provided: | Engineers available to service machinery overseas,Video technical support,Online support,Field installation, commissioning and training,Field maintenance and repair service; |

| Port: | Shanghai; | Certification: | CE,ISO CE CQC; |

| Warranty of core components: | 1 Year; | Motor Type: | AC Motor,AC Motor; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Machinery Test Report: | Provided; |

| Capacity(t/h): | 0.5-50TPH,3-50; | Supply Ability: | 30 Set/Sets per Month raymond gypsum mill in india; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Test&Installation: | Engineer Assigned; |

| Package Preview: | ; | Weight: | 10; |

| Place of Origin: | Shanghai, China,Shanghai China; | Guarantee/Warranty: | Quality approvals; |

| Application: | raymond gypsum mill in india; |

200 Mesh Barite Limestone Gypsum Calcite Grinding Mill Raymond Gypsum Mill Powder Making Milling Equipment In India

100,000TPY Limestone Grinding Line

Material: limestone

Input Size: 0-35mm

Output Size: 350mesh

Capacity: 100,000t/h

Equipment: MTW138 European Grinding Mill

Project Background

The customer is a manufacturer of desulfurizing powder. It mainly supplies the powder for surrounding power plants. They purchased a MTW110 Medium-speed Grinding Mill firstly. Afterwards, due to capacity expansion, they purchased from ZENITH a MTW138 European Trapezium Grinding Mill again.

Project Advantages

1. Considerate project service: Our technical engineers designed reasonable technical drawings, solved every technological difficulty and explained project details for the customer.

2. ZENITH’s MTM Mill changes spring connection structure innovatively, which can avoid terrible impact of large materials on the axis and bearings and enhance strength of rollers.

3. A project management team was established to supervise the progress of the whole project. By coordinating local resources, the project production was smooth.

4. Simple operation and maintenance: It is easy for local workers to operate and maintain the grinding line.

Customer Evaluation

We heard that our friends have bought the MTW European Trapezium Grinding Mills from ZENITH which have good use effect, good production of fineness powder etc. The final products were very consistent with the needs of power plants, so we signed a large contract later.

grinding milling machine,grinding milling machine for sale

This type grinding milling machine is mainly used for grinding the material with middle and low hardness, below 6% moisture, and the material should be non-explosion and non-flammability, such as: calcite, chalk,limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite,iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite,barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassiumore pumice, etc

limestone grinding mill machine Working principle

1)Raw material which has been crushed to the size specified is elevated into a hopper from which the stuff is loaded. And then through the vibrating feeder ,the materials will transferred evenly and continuously into the grinding milling machine grinding chamber for powder-processing. After this,the ground stuff is carried by the air from the blower into the classifer for regrinding.The set's airflow system is closely sealed up and circulated under the condition of negative and positive pressure.

2) The gypsum grinding plant is driven by rotation of the central axle through decelerator ,with the up end of the axle connecting to a quincunx-rack upon which the grinding equipment is fixed. The whole set equipment turns together with the axle along the grinding ring while the rollers rotate driven by the fractional force .A set of shovel are installed at the lower end of the quincunx-rack.While turning together with the rollers ,the shovels shed the stuff onto the gap between the rollers and the ring ,and that's where the stuff layer forms .The rotating rollers ,while turning together with the ring ,grind the stuff layer into powder.

3) The turning speed of the impeller can be adjusted to the requirement of the fineness of powder products .

4)limestone grinding mill machine plays an important role in ensuring the function of the grinder . As the high-speed revolving air current mixed with ground stuff is flown into the cyclone-collector ,the ground stuff is separated from the air-current

Specifications of limestone grinding mill:

| Name & Model | MTW110 | MTW138 | MTW175 | |

| Ring Roller Number(pcs) | 4 | 4 | 5 | |

| Major diameter of roller(mm) | 360×190 | 460×240 | 520×280 | |

| Inner diameter of roller (mm) | 1100×190 | 1380×240 | 1750×280 | |

| Revolving Speed(rmin) | 120 | 96 | 75 | |

| Revolving Speed(rmin) | <30 | <35 | <40 | |

| Final size(mm) | 1.6-0.045, fineness can reach to 0.038 |

1.6-0.045, fineness can reach to 0.038 |

1.6-0.045, fineness can reach to 0.038 |

|

| Capacity(th) | 3.5-10 | 6.5-15 | 13-20 | |

| Overall dimension(mm) | 8625×7933×8642 | 10920×9470×10227 | 12275×9555×9916 | |

| Main unit motor | Model | Y280M-6 | Y315M-6 | Y355M2-8 |

| Power(kw) | 55 | 90 | 160 | |

| Rotate Speed(rmin) | 980 | 990 | 740 | |

| Classifier speed regulating motor (variable frequency motor) |

Model | Y132M-4 | Y180M-4 | Y200L-4 |

| Power(kw) | 7.5 | 18.5 | 30 | |

| Rotate Speed(rmin) | 1440 | 1470 | 1470 | |

| Centrifugal induced draft fan motor | Model | Y250M-4 | Y315-4 | Y315L2-4 |

| Power(kw) | 55 | 110 | 200 | |

|

A VARIETY OF TRUSTED EXPERIENCE ZENITH has a variety of professional, reliable and efficient crushing lines all around the world. So customers have great confidence in us. |

|

INFINITE BRAND VALUE What ZENITH is doing is customizing economical and suitable production lines for customers and building brand value. |

|

1200,000 SQUARE METERS OF PRODUCITION AREA 6 large-scale manufacturing bases occupy 1200,000 square meters in total. So quick delivery is a matter of course. |

Founded in 1987, ZENITH has attained 124 patents on crushers and grinding mills over the past 30 years and has more than 30 overseas offices or branches built all over the world. Keeping customers in mind, ZENITH never stops the step forward. Wemake evolution on the outside in order to offer you better equipment; we make revolution on the inside in order to offer you better service.

-

High efficiency rock gold grinding equipment wet disc grinder for sale

-

Professional 1000 tons/day cement grinding station ball mill price

-

Black graphite vibrating ball mill

-

Nano powder steel ball mill grinder laboratory grid ball mill with grinding ball grinder

-

Small gold ore mill, small wet mill, small gold ore mill

-

Diesel engine ball mill for gold mine development for sale

-

1600 gold mill with gearbox, china wet disc mill for sale

-

Superfine Powder Complete Production Line Fluidized Bed Jet Mill

-

Energy-saving gold mine rock crusher quartz gold ore stone mill small gold ball mill

-

1100 wet mill reducer 400 gears

Other Products

-

$6500.00 - $6800.00 / set

$6500.00 - $6800.00 / set -

$40320.00 / set

$40320.00 / set