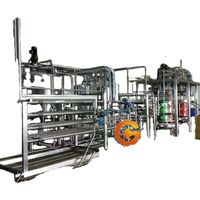

UHT PIPE FULL AUTOMATIC STERILIZER MACHINE FOR MILK / BEVERAGE

-

Supplier: Shanghai Kaiquan Machine Valve Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Crystal Cui -

Price: $1000.00 /set -

Min. Order: 1 set

| Packaging Detail: | wooden box UHT PIPE FULL AUTOMATIC STERILIZER MACHINE FOR MILK / BEVERAGE; | After-sales Service Provided: | Overseas third-party support available; |

| Video outgoing-inspection: | Provided; | Certification: | ISO9001:2000; |

| Certification: | ISO & CE; | Material: | Stainless Steel 304/316; |

| Condition: | New,New; | Key Selling Points: | High Productivity; |

| Marketing Type: | New Product 2020; | Applicable Industries: | Food & Beverage Factory,Farms,Food & Beverage Shops; |

| After Warranty Service: | Video technical support; | Brand Name: | KQ; |

| Application: | dairy ,juice ,beverage ,beer etc; | Warranty: | 1 Year; |

| Machinery Test Report: | Provided; | Core Components: | Gearbox,Motor; |

| Weight: | Based on special inquiry; | Name: | UHT PIPE FULL AUTOMATIC STERILIZER MACHINE FOR MILK / BEVERAGE; |

| Voltage: | 220v/380v,380V / 410V / 220V 50Hz/ 60Hz; | Place of Origin: | Zhejiang China; |

| Type: | Ultra High Temperature; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Dimension(L*W*H): | Based on special inquiry; | Warranty of core components: | 1 Year; |

| Capacity: | 0.5-15t/h; | Power: | 3Kw-70Kw; |

| Local Service Location: | Egypt,Canada,Turkey,United Kingdom,France,Brazil,Pakistan; | Port: | shanghai Port; |

| Package Preview: | ; | Showroom Location: | Egypt,Canada,Turkey,United Kingdom,Italy,France,Brazil; |

| Supply Ability: | 1000 Set/Sets per Month UHT PIPE FULL AUTOMATIC STERILIZER MACHINE FOR MILK / BEVERAGE; | Make to order: | Yes; |

UHT PIPE FULL AUTOMATIC STERILIZER MACHINE FOR MILK / BEVERAGE

( Dairy Milk /Beverage /Juice / Wine Processing Sterilizer Machine )

1.Machine introduction of Dairy Milk Processing Machine

Sterilization principle:UHT ultra-high temperature instantaneous sterilization machine general material

composed of centrifugal pump pumping sterilization machine hot and

cold in the heat exchange device for preheating, after high temperature

bucket full of high pressure, the material being rapidly heated to and after

the sterilization temperature keep about 3 seconds, the microbes and

enzymes were quickly kill. Material after the heat barrel by heat exchange

with cold material for cooling, average temperature below 65 °C.

Application: UHT ultra-high temperature instantaneous sterilization machine is suitable for the fresh milk,

juice, beverage, frozen sucker, and ice cream paste, soy sauce, soybean milk,

condensed milk, wine and other liquid materials.

this equipment is mainly in milk, juice, beverage, wine fluid materials of sterilization, also can be used for soymilk, fluid medicines.

Four, the main specification and technical parameter

Processing capacity:1.0-6m3/h

- sterilization temperature:115-135°C

- use steam pressure:<0.78Mpa

- high-temperature heating time:4-6S

- Material temperature:<45°C

- incoming temperature:<16°C

- Steam consumption:<0.15kg/L materials

- Motor power:Using a centrifugal pump,1.5KW

Using two centrifugal pump,3KW

equipment net:150kg

- floor space:0.9m2

Tubular Ultra-high Temperature Sterilizer (UHT).

Coil tpye UHT

Horizontal sterilizer

1: easy operation & maintenance

2: stable performance

3: long life span

4: advanced technology from abroad

Unit Feature:

(1) Continuous production, instant sterilization

(2) Good quality products due to short duration of heat exchange.

(3) Best sterilization efficiency because of super high temperature sterilization.

(4) Applicable to the sterilization to high sticky material when the unit equipped with centrifugal pump or high pressure homogenize.

(5) Less steam consumption thanks to the heat exchanger designed which uses the waste heat.

6) Less occupied area due to compact structure.

7)Easy to clean. Using CIP chemical detergent, no need to disassemble.

8) Safe use, convenient operation.

UHT PIPE WIND WIND -ROUND FULL AUTOMATIC STERILIZING MACHINE

-

Small ultra-high temperature sterilized milk processing plant milk tray type ultra-high temperature sterilizer

-

Food processing water spray sterilizer pot sterilizer machine made in China

-

Mini Cooker Autoclave Mini Cooker

-

Edible fungus sterilization sterilizing pot sterilizing pot / shiitake mushroom sterilizing pot high-pressure sterilizer

-

food cooking

-

Hot-selling food mushroom sterilization equipment

-

35L 50L 75L 100L 120L 150L Vertical Pressure Steam Sterilizer Autoclave on Hand Wheels

-

Cooking Autoclave Food Sterilization Equipment Small Back Pressure Sterilizer

-

Sterilizer

-

cooking machine

Other Products

-

$3500.00 / set

$3500.00 / set -

$6900.00 / unit

$6900.00 / unit -

$10000.00 / set

$10000.00 / set -

$3500.00 / unit

$3500.00 / unit -

$900.00 / set

$900.00 / set -

$500.00 / unit

$500.00 / unit