1000 tons per day Portland Cement Manufacturing Equipment Plant

-

Supplier: Henan Zhengzhou Mining Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Katia Zhao -

Price: $2300.00 /set -

Min. Order: 1 set

| Machinery Test Report: | Provided; | Certification: | ISO9001:14000; |

| Dimension(L*W*H): | according to different types; | Local Service Location: | None; |

| Voltage: | 380V, 400V, 415V,according to local voltage; | Supply Ability: | 4 Set/Sets per Year Portland Cement Manufacturing Equipment Plant; |

| Condition: | New; | Key Selling Points: | Long Service Life; |

| testing: | we offer; | Capacity: | 100-3000TPD; |

| Power: | various; | Brand Name: | ZK cement processing equipment; |

| Warranty of core components: | 6 months; | After Warranty Service: | Online support; |

| Core Components: | PLC; | Item: | Portland Cement Manufacturing Equipment Plant; |

| installation: | under our engineer's guide; | Weight: | various; |

| Port: | qingdao ,shanghai ,tianjin; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T; |

| Video outgoing-inspection: | Provided; | Main equipment: | rotary kiln;ball mill;rotary dryer; |

| Marketing Type: | Ordinary Product; | Warranty: | 1 year,1 year; |

| Applicable Industries: | Energy & Mining; | Packaging Detail: | nude package(Portland Cement Manufacturing Equipment Plant); |

| Spare Parts: | Supply For The Whole Year; | Place of Origin: | Henan China; |

| after sale service: | for the whole using life; | Showroom Location: | None; |

| design: | offer; |

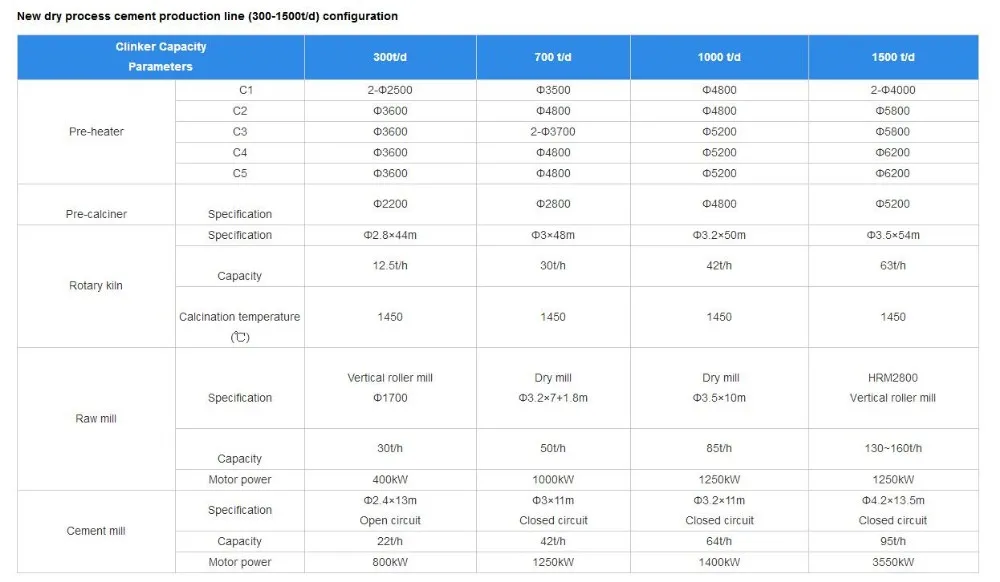

We design and manufacture devices for new type dry method cement production line, which capacity from 300t/d to 3000t/d clinker. And we can also assist the client in transacting purchaser`s credit or Chinese government`s credit while exporting.

Cement plant equipment Advantages:

1).Easy to setup,operate and adjust,customizable;

2).Pre-sales: R&D and consulting support;

3).After-sale: skills training & spare parts support;

4). High reliability;

5).Simple structure and easy to operate;

6).Easy replacement of wear and spare parts;

7).Long after sale service time;

8).High efficiency;

9).Wide ranges of choices;

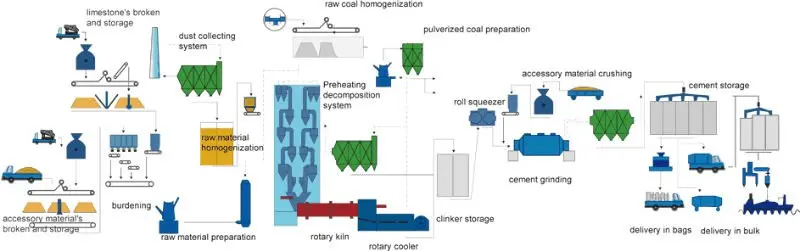

Mined limestone is delivered to the crusher for crushing by the belt conveyor, limestone after crushing ,clay, iron powder etc will be ground into powder by ball mill or vertical mill, and then transported by air delivery chute to raw meal homogenization silo for storing and further material mix. Raw meal shall get into the preheating decomposition system after homogenization where decomposition rate is about 95%, and raw meal is calcined into clinker in the rotary kiln, the formation of clinker. Clinker, gypsum and mixture is ground into qualified fineness cement in the cement mill. Powder classifier is adopted to adjust the fineness of cement, realizing energy saving production. Cement packing machine and automatic loading machine are used for bagged cement delivery, and cement bulk device for cement canning leaving factory.

Henan Zhengzhou Mining Machinery Co., Ltd. established in 1956 and located in Xingyang of Zhengzhou City of Henan Province, specially produces metallurgical machinery. It covers an area of more than 60000 m² and various building area of 35000 m². In the plant, there are workshops of cast iron, cast steel, forging, heavy machine tool processing, rivet welding and heat treatment etc. Its perfect and complete equipment, advanced detection means, strong technical force establish good foundation for the reliable production.

The main products of company include: ball mill, rotary kiln, vertical preheater, cooler, crusher, metallurgical oven, magnetic separator, flotation machine, classifier, feeder, bucket elevator, preheater, dust collector, elevator, drier, and other equipments relate to metallurgy, cement, lime, mineral processing, refractory, chemical industry. The products of Henan Zhengzhou Mining Machinery Co., Ltd have been sold to every province of China and exported to Russia, Korea, Vietnam, Malaysia, Nepal, Bangladesh, Mexico, Armenia, Africa, South America and other countries and regions.

1. Excellent installation team or installation service for you;

2. Provide you with operating and training services;

3. Help with the equipment commissioning and solve problems in trial operation;

4. Check before acceptance of single equipment or whole production line;

5. Service items including follow-up visit, customer satisfaction surveys and so on;

6. Timely provide you with necessary accessories after acceptance;

7. Provide you with warranty services of repair, replacement and refund if conditions are fulfilled.

8. Help you solve other problems.

Cement Rotary Kiln

Cement Vertical Grinding Mill

Cement Dust Collector

-

Professional lime production line lime kiln lime production factory

-

China 100TPD lime kiln for lime production line factory

-

Supply 100-2000tpd cement production line cement machinery manufacturing plant

-

Professional mini cement plant, cement production line construction project

-

Efficient Concrete Mixer Cement Mixer Force Action Mixer JS750

-

4.0×60 lime equipment rotary kiln, cement plant rotary kiln, roller table rotary kiln

-

Ex-factory price of advanced technology of Great Wall Cement Plant

-

New type ball mill sliding shoe bearing

-

cement mill/clinker grinding station/cement grinding plant

-

6000tpd 42.5 Portland cement plant

Other Products

-

$50000.00 / set

$50000.00 / set -

$1000.00 / set

$1000.00 / set -

$9000.00 / set

$9000.00 / set -

$500000.00 / set

$500000.00 / set -

$2300.00 / set

$2300.00 / set -

$9000.00 / set

$9000.00 / set