Separation Of Magnesium Oxide From Calcinated Dolomite

-

Supplier: Henan Zhengzhou Mining Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Katia Zhao -

Price: $500000.00 /set -

Min. Order: 1 set

| Port: | Main port of China; | Packaging Detail: | Standard Export Packing for equipment of magnesium production line; |

| Brand Name: | ZK; | Certificate: | ISO9001:2008; |

| Home market share: | 90%; | Marketing Type: | Ordinary Product; |

| History: | more than 50 years; | Local Service Location: | None; |

| Save energy: | 40%; | Core Components: | PLC; |

| Key Selling Points: | Long Service Life; | Increase output: | 30%; |

| Showroom Location: | None; | Machinery Test Report: | Provided; |

| Warranty of core components: | 1 Year; | Applicable Industries: | Energy & Mining; |

| Condition: | New; | After-sales Service Provided: | Engineers available to service machinery overseas,Field installation, commissioning and training; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Supply Ability: | 50 Set/Sets per Year; |

| Warranty: | 1 Year; | Video outgoing-inspection: | Provided; |

1. Introduction of Magnesium production line

We are leading manufacturer of complete magnesium production line. We have done many successful projects in both China and overseas countries. POSCO is world class iron and steel supplier in Korea. Their magnesium alloy production lines are supplied by us. We can provide plant design, equipment/spare parts supply, consultation and technical service for dolomite & magnesite calcination.

- More than 50 years experience in magnesium industry.

- Design capacity of single production line: 5,000-25,000 tons per year.

- Professional Process Design Engineers, Equipment Engineers, Electrical Engineers.

- Leading supplier of magnesium production line, and over 90% market share.

2.Process description of magnesium production line

Transported by inclined Belt Conveyor, the fine crushed dolomites will be sent to the Hopper on the top of Preheater and then discharged into Preheater by feeding chute. The high temperature gas from rotary kiln can preheat the dolomites to 800℃. Some of the dolomites can dissociate after preheating. After this process, the dolomites are push out by hydraulic push-rod and get into the Rotary Kiln for calcination with 1100-1250℃ through transfer slide. After calcination, all the materials are discharged into Cooler for cooling to less than 100℃ and then discharge to next process for grinding.

3.Main equipment of magnesium production line

- Crusher

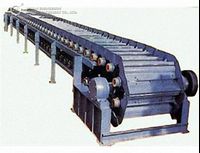

- Conveyor

- Vertical Preheater

- Rotary kiln

- Vertical cooler

- Ball mill

- Dust collector

Our advantage

- Our company's magnesium production lines at home and abroad in the lead industry,we have signed an annual output of 100000 tons of magnesium metal project with the world iron and steel giant Korean Pohang iron POSCO company.

-

The company equipment use the latest technology, the operation process is simple, and the company also provide hands-on training.

-

We produce products with high quality, durable, welcomed by the majority of users.

-

Application wide,The company can according to the customer demand design various types of production equipment, the products can operations in all sorts of conditions.

- Our magnesium production line equipment has high product quality, simple production process and other advantages, welcome customers to order.

Main Project of Magnesium production line(POSCO)

POSCO is South Korea’s seventh largest enterprise and would build a magnesium plant with capacity of 100000 tons per year. After investing more than 200 factories in China, they finally chose us as the cooperation partner.

Location:South Korea

Project name:Mg Smelting Plant with capacity of 10000tpa

Project kick off:End of 2006

Contact with ZK Corp. begins from: Oct 2009

E&P Contract signed in: Jul 2011

Key facilities:8-Pusher Pre-heater, Φ3×50 Rotary kiln, Φ2.4×20m Rotary cooler, Φ2.4×7m Ball mill and briquetter, etc.

Raw materials: Dolomite, Ferro-silicon and Fluorite.

Output: 10000tpa Magnesium ingot

Application of product: Mg alloys

Plant start-up in: Jun 2012

Henan Zhengzhou Mining Machinery Co., Ltd. was founded in 1956,it is located in Zhengzhou city which is the capital of Henan Province. After more than half a century of development, Henan Zhengzhou Mining Machinery Co., Ltd has developed to an area of 70000 square meters, plant construction area of 40000 square meters with six modern workshops, two heavy machinery workshops, one Municipal Technology Center and more than 260 sets of machining, assembling, welding and other equipments. Its fixed asset value has exceeded 100 million RMB. Henan Zhengzhou Mining Machinery Co., Ltd has become an integrated modern enterprise with scientific research, design, development, manufacturing, sales, installation, commissioning and training services.

The main products of company include: ball mill, rotary kiln, preheater, cooler, crusher, bucket elevator, dust collector,conveyor and other equipments relate to metallurgy, cement, lime, mineral processing, refractory, chemical industry. The products of Henan Zhengzhou Mining Machinery Co., Ltd have been sold to every province of China and exported to Russia, Korea, Vietnam, Malaysia, Nepal, Bangladesh, Mexico, Armenia, Africa, South America and other countries and regions. At present, Henan Zhengzhou Mining Machinery Co., Ltd is the largest equipment supplier for magnesium production and has been on the leading position for 25 years in the market.

Henan Zhengzhou Mining Machinery Co., Ltd has modern and mature administration system and perfect quality control system. It has got the ISO9001 International Quality System Certification, Environmental Protection Certification and other.

- We can supply standard export packing or packing according to customer's requirement.

- Packing and Shipping pictures for reference as following

We Got

- ISO9001:2008 Quality Management System Certification

- CE Certification (Ball Mill)

- ISO14001:2004 Environmental Management System Certification

- OHSAS 18001:2007 Occupational Health&safety Management System Certification

-

Dolomite rotary kiln sintering plant supported by engineers

-

Smooth Running Magnesium Oxide Production Line Equipment

-

Energy saving magnesium plant of capacity 15000 tpa

-

Small capacity 5000 tpa magnesium oxide manufacturing plant

-

Environmental Dolomite Calcinator for Magnesium Oxide Production Plant

-

Factory directly supply magnesium dolomite calcination plant

-

high efficiency ISO 9001 certificated automatic water discharging filtrate cylinder

-

Advanced Process Magnesium Oxide Production from Dolomite

Other Products

-

$50000.00 / set

$50000.00 / set -

$1000.00 / set

$1000.00 / set -

$2300.00 / set

$2300.00 / set -

$9000.00 / set

$9000.00 / set -

$2300.00 / set

$2300.00 / set -

$9000.00 / set

$9000.00 / set