Cell Culture Fermenter bioreactor prices

-

Supplier: Rotech Bioengineering Co., Ltd. -

Region: Shanghai, China -

Price: $5000.00 /unit -

Min. Order: 1 unit

| Automatic Grade: | Automatic; | Applicable Industries: | Manufacturing Plant,Food & Beverage Shops; |

| Video outgoing-inspection: | Provided; | Brand Name: | Rotech; |

| Ventilation: | Manual adjustment,flow meter display; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Type: | Tank Reactor; | Capacity: | 10L; |

| Package Preview: | ; | Marketing Type: | New Product 2020; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Tank pressure: | Manual adjustment,pressure gauge display;range:0-0.20Mpa; |

| Port: | Shanghai port; | Supply Ability: | 20 Unit/Units per Year; |

| Payment Terms: | L/C,Western Union,T/T; | Sterilization method: | On-site sterilization auto control or manual control; |

| Machinery Test Report: | Provided; | Condition: | New; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Packaging Detail: | International Export Wooden Case Packing, Water Proof Land and seaworthy packing of the goods shall be packed. The innermost will be packed by plastic, interior anti-shake foam and the outermost wood board. Before the shipment, the detailed packing list shall be sent out to customer.; |

| Local Service Location: | Brazil,Mexico,Russia,Thailand,Algeria; | Showroom Location: | Philippines,Brazil,Pakistan,Mexico,Russia,Algeria; |

| Feed control: | Uses peristaltic pump(Spirax,UK)to add materials; | Place of Origin: | Shanghai China; |

| Diameter to height ratio: | 1:2-3; | Voltage: | 220V/380V; |

| Warranty: | 1 Year; | Key Selling Points: | High Productivity; |

| Warranty of core components: | 1 Year; |

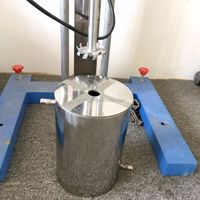

0.5-20L Glass tank bioreactor/fermenter

Human vaccine Veterinary vaccine Bioreactor Fermenter Fermentor

Introduction

Rotech has been engaged in the research, development, design and manufacture of bioreactors for more than 20 years.which is engaged in R&D, design, manufacturing, installation, commissioning and technical services of various microorganisms, plant cells and animal cell reactors (fermenters); providing customers with turnkey projects like fermentative biological projects that meet GMP requirements.

Application: human vaccines, veterinary vaccines, monoclonal antibodies, recombinant proteins, cell therapy, new drug development and production, etc.

Fermenters/Reactor specifications: 5L----6000L.

Main description

Stainless steel fermentation tank use for test project of yeast, enzymes, microorganisms such as fungi and bacteria culture test.it is made by stainless steel. equipment exquisite, beautiful imported equipment can be rivaled.

Three major components including tank, piping and control system.

Tank is SUS316L stainless,jacket is made by SUS304. Stainless steel polished precision Ra≤0.4 inside, Ra≤0.6 outside, equipment design, manufacture in accordance with GMP standards.

Technical parameters

|

Nominal volume |

10/20/30/50/80/100/200L/500L/1000L /5000L |

|

Diameter to height ratio |

1:2-3 |

|

Liquid filling factor |

70% |

|

Tank body description |

The main body is made of all stainless steel 316L tank body and jacket, with no dead corners in the tank; with special sampling for fermentation tank, discharge valve, and transfer pipeline. Adopting a wide viewing angle of the tank liquid level observation mirror, safety light, with temperature, PH, DO, defoaming, liquid level interface, injection port, refilling port, and multiple spare ports, all welds are firm, neat and beautiful |

|

Mixing method

|

Magnetic stirring or mechanical stirring one of the two optional |

|

Sterilization method

|

On-site sterilization auto control or manual control |

|

Control system |

Siemens PLC, industrial LCD touch computer control, parameters can be set to store, can be remotely connected to the computer through the USB interface, |

|

Mechanical sealing system |

High-powered stirring oar, anti-foam oar; AC electrical machine: infinite speed variation; rpm in the fermenter: 50~1000 rpm±1%, The height of the stirring oar can be adjusted |

|

Temperature detection and control |

Heat by thermostatic water tank and circulate by circulating pump (Grundfos, Denmark), auto control (cooling water+5℃) to 65℃±0.1℃, temperature probe (PT100) |

|

pH detection and control |

2.00-12.00±0.05 pH, auto control by adding acid and base, pH sensor (Mettler/Hamilton, Switzerland) and shielding lead (Mettler/Hamilton, Switzerland). fermenter is auto controlled with peristaltic pump |

|

DO detection and control |

0-150±3% displaying precision 0.1%, sensor (Mettler/Hamilton, Switzerland) and shielding lead (Mettler/Hamilton, Switzerland) |

|

Feed control

|

Uses peristaltic pump (Spirax, UK) to add materials |

|

Anti-foam control

|

Tested by sensor and added anti foamer by peristaltic pump Intake control (air) manual control rotameter |

|

Pressure detection and control |

Pressure Control: Pressure meter and digital display and digital remote control, pressure control we are compliant fermentation equipment for research, development, pilot and production applications |

|

Optional function |

|

|

A Tank weighing

|

|

| B Weighing with replenishing balance | |

| C Automatic control of air flow | |

| D Online detection and control of methyl alcohol content | |

|

E Bypass pure oxygen |

|

| F Online detection of redox potential | |

|

G Tank pressure detection |

|

|

H Online detection of O2 and CO2 content in tail gas |

|

| I Automatic tank cleaning function | |

| J Automatic sterilization function | |

| K Tank cover automatic lifting function | |

-

Laboratory bioreactor filtration crystallization single and double layer 20L 10L 5L 50L 100L 200L jacketed glass reactor

-

Hot sale new stainless steel industrial chemical decarboxylation reactor

-

Laboratory 20L Chemical Reactor Stainless Steel Reactor

-

500ml catalyst test equipment chemical pressure reactor

-

Reasonable price epoxy resin reactor production line

-

High-quality AC reactor 11kw 30A RACL 2%-30/11 three-phase AC line reactor

-

Bromine production line

-

Plant Direct Methanol Synthesis Reactor System with Insulation Function

-

Benchtop desktop small glass laboratory 5l 10l microbiology photo plant cell bacterial fermentation fermenter fermenter bioreactor

-

SS316 Jacketed container for laboratory dispensing mixing