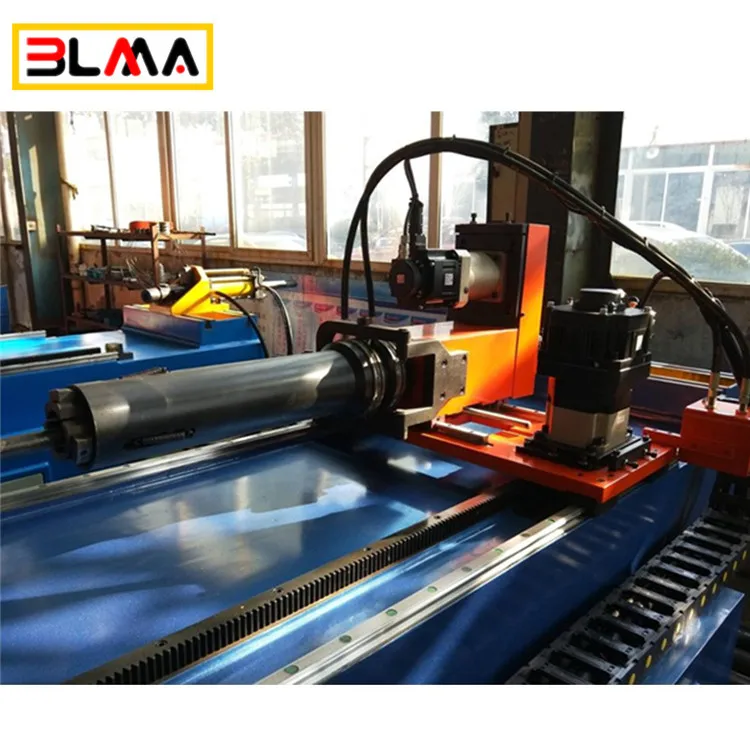

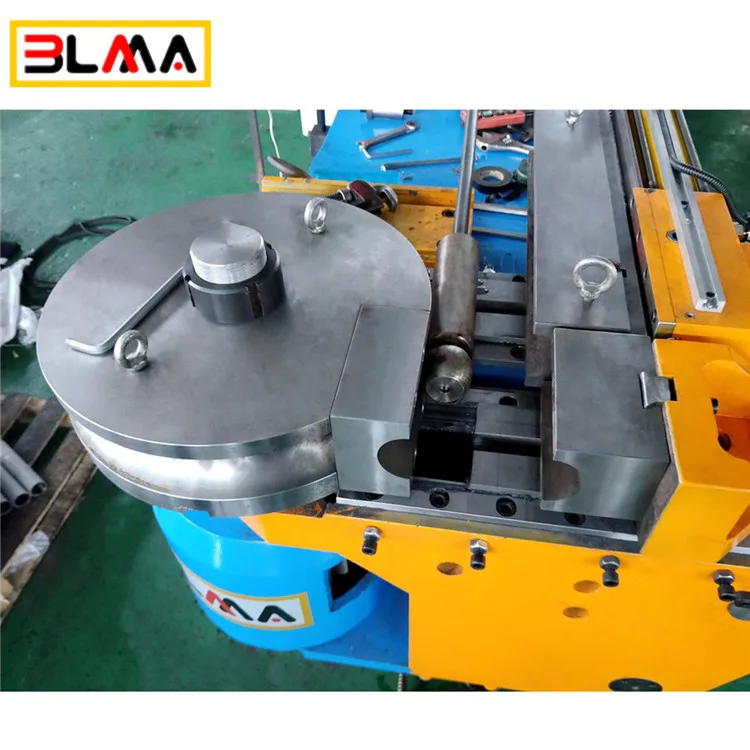

Serpentine 3 axis twin head ladder copper iron ss cnc tube pipe bending machine

-

Supplier: Nanjing Blma Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Jenny Yao -

Price: $4100.00 /set -

Min. Order: 1 set

| Supply Ability: | 200 Set/Sets per Month; | Packaging Detail: | pipe bender machine packing: Exported standard wooden case of each set.; |

| Brand Name: | BLMA; | Condition: | New; |

| Key Selling Points: | Competitive Price; | Weight (KG): | 2500; |

| Max feeding length: | 3000mm; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Machine size: | 5000X1300X1500mm; | Applicable Industries: | Manufacturing Plant,Farms; |

| Max bending diameter: | 50mm; | Place of Origin: | Jiangsu China; |

| Video outgoing-inspection: | Provided; | Bending Precision (Deg): | 1°; |

| Machinery Test Report: | Provided; | Certification: | ce; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Max. Bending Angle (Deg): | 190; |

| Item: | Bender Electric Automatic CNC SS Rolling Pipe Bending Machine; | Max bending radius: | R250mm; |

| Machine weight: | 2500kg; | Core Components: | Bearing,Motor,Pump,PLC,Pressure vessel; |

| Extra Services: | Machining; | Power (kW): | 5.5; |

| Warranty of core components: | 1 Year; | Showroom Location: | South Korea,Sri Lanka,Romania,Viet Nam; |

| Marketing Type: | Ordinary Product; | Material / Metal Processed: | Aluminum, cooper, iron, stiainless steel; |

| Warranty: | 12 months,1 Year; | Max wall thicness: | 3mm; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Machine Type: | Pipe and Tube Bending Machine; |

| Port: | Shanghai; | Local Service Location: | South Korea,Sri Lanka,Romania,United Kingdom,Viet Nam,Russia; |

| Max bending angle: | 190°; | Bending Radius (mm): | 10 - 250; |

| Automation: | Automatic; |

Serpentine 3 axis twin head ladder copper iron ss cnc tube pipe bending machine

Working vedio of pipe bender machine: https://youtu.be/FNn7z17RAW0

****We have multi models of bending machine for your choices. Pls send us your requirments, we will quote you accordingly.****

| Specifications of DW50CNC-2A-1S Tube Bender/Pipe Bending Machine | |

| Technical: | Cold Bending |

| Electrics: | France Schneider |

| System: | Japan Mitsubishi |

| Hydraulic parts: | Japan Yuken |

Main Features:

- Using the microcomputer control, automatic bending.

- Safety:the emergengcy stop button on the bending arm.

- Dialogue operation, easy to study and understand.

- Partition hypothesis speed, high pipe-bending precision up to ±0.1°

- 16 groups pipe-bending information storage, all angles work forms a coherent whole

- The mandrel automatically in and out, saving much time

- Suitable for bending steel pipe, stainless steel pipe, copper pipe, aluminum pipe, etc

- Can install auxiliary push die, low returning-core function, can bend thin pipes

- Special fitting: special mold, anti-wrinkle board, auxiliary push installation, etc

| Parameters | |

| Max bending capacity | ø50mmX3mm |

| Max bending radius | R250mm |

| Min bending radius | According to pipe diameter |

| Max bending degree | 190° |

| Max feeding length | 3000mm |

| Bending speed | Max 85°/s |

| Rotary speed | Max 200°/s |

| Feeding speed | Max 1000mm/s |

| Bending accuracy | ±0.1° |

| Rotary accuracy | ±0.1° |

| Feeding accuracy | ±0.1mm |

| Bending method | Hydraulic bending(2A), Servo bending(3A) |

| Rotary servo motor power | 750W |

| Feeding servo motor power | 1KW |

| Motor power | 5.5KW |

| Max oil pressure | 12Mpa |

| Machine weight | 2500kg |

| Machine size | 5000X1300X1500mm |

Bending Samples:

Packaging: Each set in an exported standard wooden case.

Delivery time: Within 20 days after receiving deposit.

| Pre-service: |

| 1.We will help you confirm the model of our machine according to your offered pipe information. |

|

2.You are very welcome to see our machine how to work in the factory before you place an order with us. |

| Aftersales-service: |

| 1.Free installation, trial start and adjustment, training. |

|

2.We guarantee machine quality for one year. During this year, if spare parts of the machine were damaged, we can send the components to the customer by DHL,TNT freely. |

|

3.Our factory provide the service for the customer forever, if the customer need operation help,we provide 24 hours on-line reply service. |

1. How to choose the pipe/tube bending machine?

You have to inform us following details:

- Max. outside diameter

- Wall thickness range

- Bending radius (CLR)

- The pipe material

- The drawings if possible

2.Do you provide any training to make sure our user can operate the machine very well?

1)We will provide detailed video and instruction book for this machine;

2)We also offer training in our factory to all the clients,and we will arrange everything for you during these days in our city,to make sure every client will be the expert in using our machine!

3. How long warranty can you provide?

Our machine warranty is one year,and we use all the stable compoenents with long working life!

And we can also send our technician to do the after-sale service in client's factory!

4.What kind of solution you can offer to make sure your pipe bending machine can do our job?

1)We will help you confirm the model of our machine according to your offered pipe information.

2)Before you start the order for this big value machine,you can offer your workpiece drawing to us.

We can design the tooling to make your products in our workshop,after you are sure that the workpiece is good,then we can confirm the order finally.

3)You can visit us to check how to bend your product before you start the order.During this period,you can also learn how to use this machine well!

Our workshop:

Click for More Information!!!

-

Easy to operate hydraulic stainless steel round square pipe bending machine bending machine

-

Hydraulic pipe bending machine CNC pipe bending machine steel pipe bending machine price

-

AH Tube Bending Machines for (Profile, Section, Rotary Draw Bander)

-

6 ton hydraulic pipe breaker HHW-1A

-

Door and window guardrail square tube metal pipe thread corrugated stranding machine

-

16 Tons Heavy Duty Hydraulic Pipe Bender Pipe Metal Steel Exhaust Pipe Bending With 8 Dies

-

Hydraulic Square Tube Bender Stainless Steel Rolling Tube Bender Price

-

Hydraulic Small Stainless Steel Mini Tube Bender Conduit Manual Tube Bender

-

76 weighted pipe bender square pipe bender 4 inch square pipe bender low carbon steel pipe bender

-

CYW-G76 Multifunctional Manual Bending Machine

Other Products

-

$2600.00 / set

$2600.00 / set -

$1600.00 / set

$1600.00 / set -

$4500.00 / set

$4500.00 / set -

$1250.00 / set

$1250.00 / set -

$4100.00 / set

$4100.00 / set -

$4600.00 / set

$4600.00 / set -

$10500.00 / set

$10500.00 / set -

$1400.00 / set

$1400.00 / set -

$17500.00 / set

$17500.00 / set -

$4500.00 / set

$4500.00 / set