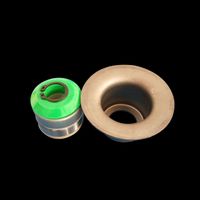

Metal Foundry Precision Gs 45 Steel Casting Bearing Housing

-

Supplier: Shanghai Matech Machinery Manufacture Corporation Ltd. -

Region: Shanghai, China -

Contact: Mr Richard LI -

Price: $2.10 / >=200 kilograms -

Min. Order: 200 kilograms

| Applicable Industries: | Machinery Repair Shops,Food & Beverage Factory,farms,Printing Shops,Energy & Mining,Food & Beverage Shops,Advertising Company; | Model Number: | customized; |

| Brand Name: | MATECH; | Packaging Detail: | Foundry Lost Wax Casting Parts Steel Cast Iron: Pallet , or multilayer wooden box with big plastic bags inside. The box can be definitely made according to the size and shape of gs 45 steel casting.; |

| Lead Time: | about 50 days for gs 45 steel casting; | Surface Treatment: | Surface Passivatin, Polish. As customer request; |

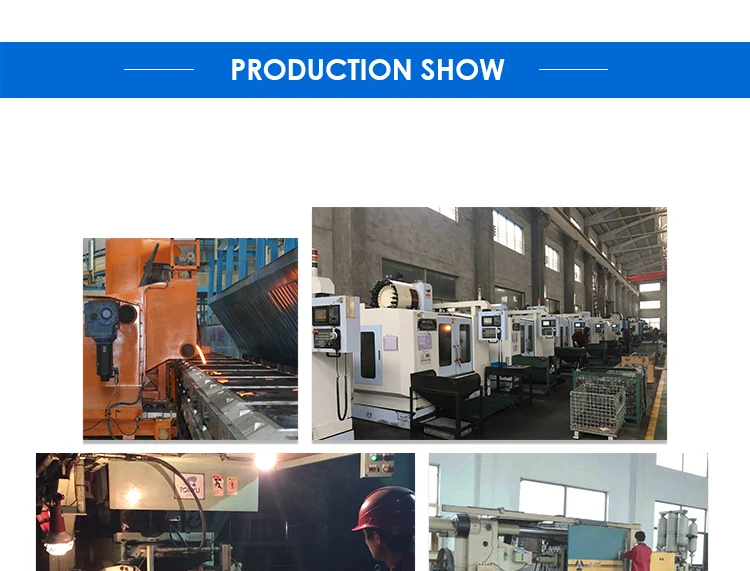

| Supply Ability: | 200 Ton/Tons per Month Of gs 45 steel casting; | Machining Process: | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.; |

| Package: | Multiplayer wooden box/pallet, with big plastic bag inside; | Place of Origin: | Zhejiang China; |

| Manufacturing Process: | Investment casting, option Lost wax casting; | Item: | Metal Foundry Precision Gs 45 Steel Casting Bearing Housing; |

| Port: | Shanghai, or as customer request; | Machining Tolearnce: | Up to IT7, Ra 0.8~3.2 , according to customer requirement; |

| Casting Tolerance: | CT4-8 for steel casting; | Material: | Carbon Steel and Alloy Steel etc. As customer request.,steel; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,or as customer request; | Service: | Supply metal parts solution as per customer's drawings/ samples; |

|

Item Name |

Metal Foundry Precision Gs 45 Steel Casting Bearing Housing |

|

General Products |

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, , transmission shaft , transmission gear etc. |

|

Main Blank Process for Stainless Steel Casting |

Investment casting (wax mold made by middle temperature wax) /Precision casting ; |

|

Blanks Tolerance -Casting Tolerance |

CT7-8 for Lost wax Casting Process |

|

Applicable Material for steel casting |

Carbon Steel, Alloy Steel, |

|

Casting Blank Size |

2 mm-600mm / 0.08inch-24inch according to customer requirement |

|

Casting Blank Weight |

Range from 0.01kg-85kg |

|

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ |

|

Machining Tolerance |

From 0.005mm-0.01mm-0.1mm |

|

Machined Surface Quality |

Ra 0.8-Ra3.2 according to customer requirement |

|

Applicable Heat Treatment |

Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching etc. |

|

Applicable Finish Surface Treatment |

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, etc. |

|

MOQ for batch order |

For casting: 100pcs For Machining: 50pcs |

|

Lead Time |

50 days for gs 45 steel casting |

1. Are you a manufacturer or a trading company?

1. Are you a manufacturer or a trading company?

We are a professional manufacturer with over 15 years’ export experience for designing and producing vehicle machinery parts.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

3. Can you make casting according to our drawing?

Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

4. Can you make casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5. What’s your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of casting.

-

High quality seated bearing F209 Insert ball bearing supplier F209

-

Gray cast shell, radial insert ball bearing with seat P210

-

High Quality Bearing Parts S2202 2RS Bearing Housing

-

Wholesale stamped bearing housing deep groove ball bearing stamped bearing housing

-

China Bearing End Cover TK89-6204 Belt Conveyor Idler Roller Accessories

-

Trinity Premium TKll6204-108 Construction Site Bearing Covers and Labyrinth Seals

-

Idler bearing housing DTII6204 -89 and related seals

-

Stamped DT II steel housings for bearings

-

Plastic end roller bearings/roller end housings for conveyors

-

High quality conveyor roller bearing housings 6204 for conveying systems

Other Products

-

$2.00 / piece

$2.00 / piece -

$0.10 / piece

$0.10 / piece -

$50.00 / piece

$50.00 / piece -

$2.12 / kilogram

$2.12 / kilogram -

$2.73 / kilogram

$2.73 / kilogram -

$0.20 / piece

$0.20 / piece -

$251.00 / piece

$251.00 / piece

1. Are you a manufacturer or a trading company?

1. Are you a manufacturer or a trading company?