Stamped DT II steel housings for bearings

-

Supplier: Qufu Zhuoyue Heavy Industry Science & Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Tim Gao -

Price: $0.40 / >=50 pieces -

Min. Order: 50 pieces

| Certificate: | ISO9001:2015 | application: | Belt Conveyor Roller |

| OEM order: | Produce according to your drawing | Material: | SPHC/SPCC, steel |

| General tolerances: | 0.001mm | Supply capacity: | 50000 pieces per day |

| payment terms: | L/C, Western Union, T/T | Radial/axial runout: | Within 0.25 |

| Packaging Details: | Standard export packaging | Name: | bearing seat |

| Applicable industries: | Manufacturing plants, machinery repair shops, food and beverage plants, farms, construction, energy and mining | port: | Qingdao |

| Package preview: | thickness: | 2.5-6mm | |

| brand: | Bonjour | model: | DT II |

| Origin: | China | type: | DT II housing |

| Outer diameter: | up to 230 mm |

Stamped DT II steel housings for bearings

DT II housing

We have become the leader of bearing housings in China.

application:

The DT II bearing housing is an integral part of the belt conveyor and a necessary part of the conveyor roller. Belt conveyors are commonly used in mining, seaports and many other places.

feature:

DT II housing has good sealing, including 3 plastic or nylon sealing rings and 3 metal sealing rings.

Other related housings for bearing products:

TK Housings TK II Housings

OEM housings for bearings Large bearing housings 6mm thick

Our advantages on bearing housings:

1. More than 20 years of rich experience in bearing housing manufacturing, started in 1995.

2. It has 7 stamping production lines, 2 automated robot lines, and 3 accessory lines to achieve high production capacity.

3. Molds can be designed and manufactured by ourselves, so OEM and ODM orders are welcome, no problem.

4. Professional technical team members with 18-50 years of working experience in bearing housings are always ready to solve problems for you.

5. Strict quality control of each process and advanced testing equipment to ensure high quality.

6.We have cooperated with many Fortune 500 companies and believe in our ability.

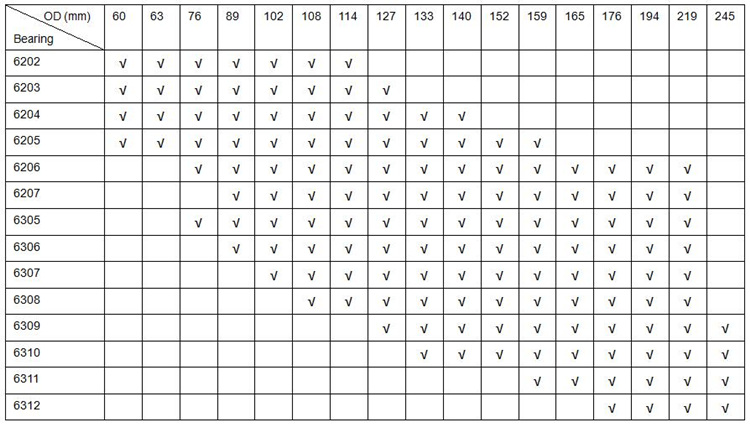

Conveyor roller housings with bearing specifications:

Factory Tour:

Our robotic lines for bearing housing production:

The housing of the bearing production process:

Machine display:

production process:

1. Mold design and production

2. Stamping: including material cutting, 3-5 times of stamping, finishing, punching, trimming.

3. Clean and oil

4. Oiled packaging

QC:

1. 100% high-quality raw materials come from top suppliers

2. Precision mold

3. Strict hot stamping 3-5 times

4. The appearance has no scratches and burrs

5. Advanced testing equipment to ensure accuracy specifications

6. The general tolerance is accurate to 0.001mm

7. Standard packing protects the bearing seat

Quality inspection exhibition:

Packaging display:

Exhibition display:

We have participated in many exhibitions in different countries. Our bearing housings have won the trust of many customers. We will participate in more exhibitions in the future.

market:

For more than 20 years, we have provided our products to many customers from nearly 20 countries including Italy, Germany, the United States, Australia, Chile, Indonesia, India, Korea, and Russia.

Serve:

1, Customize the bearing seat according to your drawing

2. Accept lettering according to your requirements

3, Provide free samples

-

High quality seated bearing F209 Insert ball bearing supplier F209

-

Gray cast shell, radial insert ball bearing with seat P210

-

High Quality Bearing Parts S2202 2RS Bearing Housing

-

Wholesale stamped bearing housing deep groove ball bearing stamped bearing housing

-

China Bearing End Cover TK89-6204 Belt Conveyor Idler Roller Accessories

-

Trinity Premium TKll6204-108 Construction Site Bearing Covers and Labyrinth Seals

-

Idler bearing housing DTII6204 -89 and related seals

-

Plastic end roller bearings/roller end housings for conveyors

-

High quality conveyor roller bearing housings 6204 for conveying systems

-

DJE 205-304 universal thickened vertical side cover eccentric cover bearing seat

Other Products

-

$0.30 / piece

$0.30 / piece