Steel Stamped Bearing Housing for Rollers

-

Supplier: Qufu Zhuoyue Heavy Industry Science & Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Tim Gao -

Price: $0.30 / >=50 pieces -

Min. Order: 50 pieces

| General Tolerance: | 0.001mm; | Application: | Belt Conveyor Roller; |

| Packaging Detail: | Standard export packing; | Port: | Qingdao; |

| Outer Diameter: | Up to 230mm; | Applicable Industries: | Food & Beverage Factory,Construction works ,Energy & Mining; |

| Brand Name: | Zhuoyue; | Certificate: | ISO9001 : 2015; |

| Model Number: | OEM; | Type: | OEM Bearing Housing; |

| Payment Terms: | L/C,T/T,Western Union; | Material: | SPHC/SPCC; |

| Supply Ability: | 50000 Piece/Pieces per Day; | OEM Orders: | Produce according to your drawing; |

| Radial/Axial Runout: | Within 0.25; | Name: | Bearing Housing for Rollers; |

| Place of Origin: | China; | Thickness: | 2.5-6mm; |

| Material: | Steel; |

Steel Stamped Bearing Housing for Rollers

Bearing Housing for Rollers

We have become the top leader of Bearing Housing for Rollers production in China.

Application:

Bearing Housing for Rollers are necessary part for conveyor roller which is the component of belt conveyor. Belt conveyors are common used in mining, sea port and many other places.

Features:

We have our own mold design and making team, so bearing housing design is no problem for us.

Also we can produce different Bearing Housing for Rollers according to your bearing housing drawing.

Other related products:

TK II Bearing Housing for Rollers DT II Bearing Housing for Rollers

TK Bearing Housing for Rollers 6mm Thick Large Bearing Housing for Rollers

Our advantages on Bearing Housing for Rollers:

1. More than 20 years rich experience in manufacturing Bearing Housing for Rollers since 1995.

2. With 7 stamping production lines, 2 automatic robot lines and 3 accessory lines, to achieve high capacity.

3. Mold can be designed and made by ourselves, so OEM and ODM orders are welcome and no problem.

4. Professional technical team members with 18-50 years working experience in Bearing Housing for Rollers are always ready to solve your problems.

5. Strict quality control for every process and advanced inspection equipment, to ensure the high quality.

6. We have cooperated with several of the world top 500 companies, so just trust our capability.

Production process:

1, Mold designing and making

2, Stamping: includes material cutting, 3-5 times stamping, final finishing, hole punching and edge trimming.

3, Cleaning and greasing

4, Oil coated and Packing

Quality Control:

1, 100% good raw material from top suppliers

2, Precision mold

3, Strict 3-5 times stamping

4, Appearance with no scratch or burrs

5, Advanced inspection equipment to ensure the precision specification

6, General tolerance accurately to be 0.001mm

7, Standard packing to protect the bearing housing

Production process:

1, Mold designing and making

2, Stamping: includes material cutting, 3-5 times stamping, final finishing, hole punching and edge trimming.

3, Cleaning and greasing

4, Oil coated and Packing

Quality Control:

1, 100% good raw material from top suppliers

2, Precision mold

3, Strict 3-5 times stamping

4, Appearance with no scratch or burrs

5, Advanced inspection equipment to ensure the precision specification

6, General tolerance accurately to be 0.001mm

7, Standard packing to protect the bearing housing

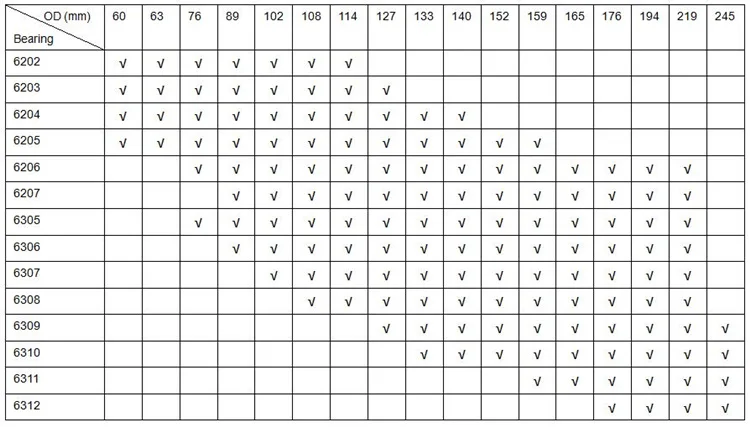

Usual Bearing Housing for Rollers Specification:

Factory Show:

Our Robot Line for Conveyor Roller Shaft Bearing Housing production:

Bearing House Production Process:

Machine Show:

QC Show:

Packing Show:

Exhibition Show:

We have attended many exhibitions in different countries. Our bearing housing has won the trust of many customers. And we will attend more exhibitions in the future.

Market:

Over the 20 years ,We have supplied our products to many clients from almost 20 nations, Italy, Germany, USA, Australia, Chile, Indonesia, India, Korea, Russia, etc.

Service:

1, Customize the bearing housing according to your drawing

2, Accept lettering according to your requests

3, Free samples are available

-

High quality seated bearing F209 Insert ball bearing supplier F209

-

Gray cast shell, radial insert ball bearing with seat P210

-

High Quality Bearing Parts S2202 2RS Bearing Housing

-

Wholesale stamped bearing housing deep groove ball bearing stamped bearing housing

-

China Bearing End Cover TK89-6204 Belt Conveyor Idler Roller Accessories

-

Trinity Premium TKll6204-108 Construction Site Bearing Covers and Labyrinth Seals

-

Idler bearing housing DTII6204 -89 and related seals

-

Stamped DT II steel housings for bearings

-

Plastic end roller bearings/roller end housings for conveyors

-

High quality conveyor roller bearing housings 6204 for conveying systems

Other Products

-

$0.40 / piece

$0.40 / piece