Professional Factory Cast Exhaust Turbo Sand Casting Intake Manifold

-

Supplier: Shanghai Matech Machinery Manufacture Corporation Ltd. -

Region: Shanghai, China -

Contact: Mr Richard LI -

Price: $2.73 / >=100 kilograms -

Min. Order: 100 kilograms

| Package for Precision Cnc Machining: | Multilayer wooden box/pallet, with big plastic bag inside; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,or as customer request; |

| Material: | Aluminum Alloy Iron, Steel, etc. Or As customers request.; | Brand Name: | Matech; |

| Machining Process: | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.; | MOQ for mass production: | 100pcs normally; |

| Service: | OEM/ODM for sand casting intake manifold; | Surface Treatment: | Anodize, Painting; |

| Item: | Professional Factory Cast Exhaust Turbo Sand Casting Intake Manifold; | Lead Time: | 45 days for sand casting intake manifold; |

| Place of Origin: | Zhejiang China; | Model Number: | Customized; |

| Manufacturing Process: | Casting, Forging, Machining or As customers request.; | Supply Ability: | 200.0 Ton/Tons per Month of sand casting intake manifold; |

| Port: | Shanghai, or as customer request; | Casting Tolerance: | CT5-7 for sand casting intake manifold; |

| Packaging Detail: | Professional Factory Cast Exhaust Turbo Sand Casting Intake Manifold Pallet , or multilayer wooden box, the box can be definitely made according to the size and shape of sand casting intake manifold; | Package Preview: | ; |

Shanghai Matech Machinery Manufacture Co., Ltd.

Shanghai Matech Machinery Manufacture Co., Ltd.

--Branch of Matech Industry Ltd.

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system etc.

With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market.

to satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

Blank Production Process For Investment Casting:

We have a variety of casting processes: investment casting, precision casting, Lost wax casting, permanent casting, low pressure casting, etc. No matter what process you want to produce your product, we can help you.

Make Wax Mould→Mould Group Tree→Slurry→Dewaxing→Air Dired→Sanding→Slurry→Roasting→Pouring→Insulation→Clean Up

| Item | Professional Factory Cast Exhaust Turbo Sand Casting Intake Manifold |

|

Main Blank Process

|

Casting,Investment casting ,Lost Wax Casting,Fofging etc. |

| Blanks Casting Tolerance | CT4-8 for sand casting intake manifold |

| Applicable Materials |

Aluminum Alloy:6061,7075, ADC12, A380

Iron: GGG20

Carbon steel, Low Carbon steel, middle carbon steel, G35, G45, WCB, WCA, WCC, ISO 340-550, etc. OR According to customer requirement.

|

| Casting Blank Size | 2 mm-600mm / 0.08inch-24inch according to customer requirement |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching /Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Heat Treatment | Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching. |

| Applicable Surface Treatment | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish |

| MOQ for mass production | 500KG for sand casting intake manifold |

| Lead Time | about 50days from the receipt date of sand casting intake manifold |

1. Are you a manufacturer or a trading company?

We are a professional manufacturer with over 15 years' export experience for designing and producing vehicle machinery parts.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

3. Can you make casting according to our drawing?

Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

4. Can you make casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5. What's your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of casting.

-

Hot selling car replacement 1457008 oil seal

-

Transmission Control Unit Part No. 29551869/28452395 Allison Transmission A59 TCM Control Module

-

Best Selling 3 in 1 Air Electrical Assembly Power Cord 15ft Power Spiral Cable Kit with Gladhands

-

Hot Sale Car Replacement 5411310131 Repair Kit Compressor

-

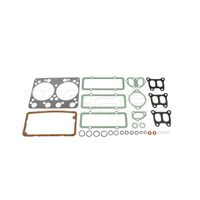

Engine Gasket Set OEM 550182 551415 Cylinder Head Gasket

-

Complete non-porous bumper, black, 2007-2017, Freightliner Cascadia

-

Engine Model Overhaul Complete Manufacturer OEM 550229 551484 Cylinder Head Gasket Kit

-

Hot Sale High Quality Cheap Truck Tires Trailer Tires For Sale

-

Yuchai 6A/6108 Alternator JFZ2503 X/A3008-3701100/JFZ2902TJ/28V/55A/2PK/JFZ2902L X/Factory Verified Supplier Mechanical Parts

-

Truck engine thermostat 504238777 500381350 504027457 5801375230 5801630047 Coolant thermostat with gasket

Other Products

-

$2.00 / piece

$2.00 / piece -

$0.10 / piece

$0.10 / piece -

$50.00 / piece

$50.00 / piece -

$2.12 / kilogram

$2.12 / kilogram -

$2.10 / kilogram

$2.10 / kilogram -

$0.20 / piece

$0.20 / piece -

$251.00 / piece

$251.00 / piece