Recycling machine for PET PP HDPE LDPE LLDPE ABS PVC PE Film Jumbo Woven Bags Garbage Bottle Flake Drum Pallet Lump Pipe

-

Supplier: Jiangsu Aceretech Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Kelvin Bian -

Price: $140000.00 /set -

Min. Order: 1 set

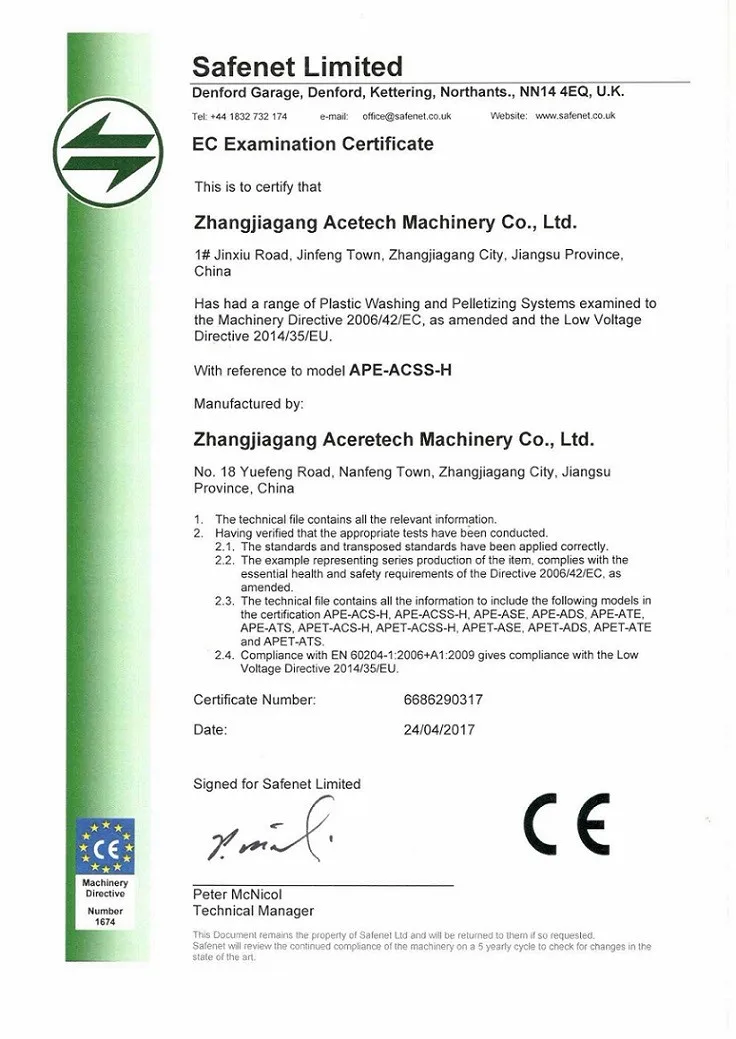

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Certification: | CE; |

| Machine test support: | Yes, with clients' materials; | application: | PE raffia recycling machine; |

| Showroom Location: | turkey,UNITED KINGDOM,Mexico,RUSSIA,south africa; | Cutting way: | Water-ring Die-face, Strand, Underwater; |

| After-sales Service Provided: | Video technical support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Engineers available to service machinery overseas; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,farms,restaurant,HOME USE,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company,plastic recycling; |

| Local Service Location: | turkey,UNITED KINGDOM,Mexico,RUSSIA,japan; | Packaging Detail: | Bubble film, stretch film, pallet for PE film recycling machine; |

| Final product: | Pellets/granules; | Condition: | New; |

| Application: | recycle plastic of small bulk density; | ACS-H series: | ACS300/80, 500/100, 800/120, 1000/140, 1200/160, 1400/180; |

| Payment Terms: | L/C,T/T; | Compactor volumn: | 1000L; |

| Key Selling Points: | Automatic; | PLC intelligent control system: | Schneider/Siemens; |

| Port: | SHANGHAI; | Screw: | Single-screw, 140-150mm; |

| Weight (T): | 18; | Brand Name: | ACERETECH; |

| Power (kW): | 408; | Warranty: | 1 YEAR; |

| Voltage: | 380V 50HZ or Customized; | Automatic Grade: | Automatic; |

| Place of Origin: | China; | Dimension(L*W*H): | 4000*1800*3800mm; |

| Melt filter: | Plate, Column/Piston, back-flush; | Supply Ability: | 10 Set/Sets per Month; |

Mother and Child Plastic Recycling Machine for PE Raffia

Aceretech's high efficiency, one-step plastic recycling machine ACS-H is designed for the reprocessing of PE polyethylene (HDPE, LDPE, LLDPE), PP polypropylene flexible packaging material (BOPP, OPP), PET film, printed and non-printed, and foamed material such as EPE EPP EPS, also filament, raffia, nylon, etc. This compactor integrated pelletizing system eliminates the need of pre-cutting the material, requires less space and energy consumption while producing high quality plastic pellets at a productive rate.

1) Simple design, user-friendly operation.

2) Siemens original motors, ABB/Schneider converts.

3) Siemens PLC, Celduc solid relay, Gefren pressure sensors, Omron Temperature controllers, LS air switch.

4) Lower investment cost for a high quality and durable machine.

5) Low energy consumption, High output capacity.

6) Aceretech produces 10 sets of ACS-H series compacting pelletizing machines per month. Usual delivery time: 60 days.

7) Engineers are available to do commissioning work abroad.

FOR MORE DETAILS OF BOPP film recycling machine PLEASE FEEL FREE TO CONTACT US.

Belt conveyor

Plastic film, bags, filament, raffia are conveyed by belt conveyor up into the compactor. Hauling roller for feeding rolls of film. Speed adjusted by ABB/Schneider inverter.

Metal detecotor as an option, to detect and notify to remove metals.

Compactor / Agglomerator

The rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high speed rotatory blades will heat and let scraps shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

Plasticization (Extruder)

A specialized single-screw extruder applied to gently melt the pre-compacted material. The plastic scraps will be well melted, plasticized in the extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiently, especially suitable for heavy printed film and material with much moisture.

The requirements on the filter technology depend on the characteristics of the input material as well as the planned use of final granules. Regular single-plate/piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on the end of the extruder to present significant filtration performance.

Water-ring Die-face cutting system

Water-ring die-face/Strand cutting methods are usually adopted. In water-ring die-face cutting system, the rotary cutting blades will be pneumatically fit completely and closely to the die-face surface to ensure efficient cutting. Rotary speed of the blades is automatically adjusted by module system according to melt pressure at the die face.

Dewatering system

Advanced vibration sieve combining with horizontal centrifugal presents high performance of drying.

Electric control system

Siemens PLC intelligent control system, user-friendly operation.

International famous brands: Siemens, Celduc, Gefren, Omron, etc.

LDPE bubble film

ACS-H BOPP film recycling machine

PP PE packaging film

ACS-H BOPP film recycling machine

PP film

ACS-H BOPP film recycling machine

LDPE

PP (woven bag)

PP

Pre-sales service

* Inquiry and consulting support.

* Test-running support.

* Visit our Factory.

After-sales service

* Training how to instal and use the machine.

* Engineers available to service machinery overseas.

-

Sevenstars PET bottle recycling machine/plastic cleaning machine/plastic recycling equipment

-

Best Price Waste Plastic PP PE ABS PS PET Recycling Pelletizing Machine Recycling Plastic Pelletizing Machine Production Line

-

pp woven bag recycling cleaning line plastic cleaning recycling machine garbage recycling plant

-

Waste plastic recycling line PET bottle flakes crushing and cleaning production line

-

Waste recycling machine for plastic bottles/pp pe recycling line for washing hdpe flakes

-

Plastic Recycling Machine Cost / Plastic Recycling Plant / Recycling Plastic Pelletizer Price

-

PET bottle recycling machine/plastic washing machine/plastic recycling plant

-

Large capacity 2000kg/hr PET bottle recycling line

-

PP PE/PET Flake Washing Machine Floating Tank Floating Washing Machine for Plastic Recycling Washing Line

-

Polyester Fiber Recycled Making Machine/Waste PET plastic extruder machine/plant

Other Products

-

$2000.00 - $20000.00 / set

$2000.00 - $20000.00 / set