Tianjin Bridge Brand ER70S-6 CO2 mig welding wire foshan

-

Supplier: Tianjin Bridge Welding Materials Group Co., Ltd. -

Region: Tianjin, China -

Contact: Mr Luca Sun -

Price: $0.70 /kilogram -

Min. Order: 1 kilogram

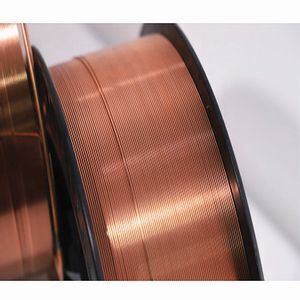

| Weight: | 15kg 20kg 250kg 350kg; | Dia.: | 0.6-2.0mm; |

| Model Number: | YGW-11 ER70S-6; | Packing: | plastic spoool metal spool drum; |

| Shield gas: | 100% CO2; | Packaging Detail: | mig wire:15kg/spool/carton,72carton/pallet=1.08tons; 20kg/spool/carton,60carton/pallet=1.2tons; 250/350kg/drum, 2/4drums/pallet.; |

| Feature: | good performance; | Single package size: | 70X70X50 cm; |

| Package Preview: | ; | Material: | carbon steel; |

| Surface: | cooper coated; | Product name: | MIG WIRE; |

| Payment Terms: | TT LC; | Single gross weight: | 68.0 KG; |

| Selling Units: | Single item; | Application: | carbon steel and low alloy steel; |

| Diameter: | 0.6-2.0mm; | Certificate: | ISO ABS BV CCS DNV.GL; |

| Flux Content: | C1; | Welding type: | CO2 Torch; |

| Place of Origin: | Tianjin China; | Standard: | YGW ER70S-6; |

| Brand Name: | BRIDGE OR OEM; |

Tianjin Bridge Brand ER70S-6 CO2 mig welding wire foshan

Applications: It can be used in tee welding of carbon steel and low alloy steel in the corresponding strength grade, which can be used in engineering machinery, ship, vehicle manufacturing, petrochemical and other industries.

Characteristics: wire THQ-50C is 500MPa level carbon steel wire. It take CO2 or 80%Ar+20%CO2 gas shielded arc welding. The welding spatter is small, and it has beautiful appearance, high cladding efficiency and small weld metal porosity sensibility. The welding technology of all positions is good.

Precautions:

1.Clear rust, oil, water and other impurities on the weldments before welding.

2.The size of the welding line energy will directly affect the mechanical properties of the weld. The size of the line energy depends on the important level of the structure. The more important the structure is, the smaller the line energy should be taken.

3.Welding parameters are only provided for reference. The user should develop an appropriate production welding specifications acccording to the circumstances.

PRODUCT DISPLAY |

ER70S-6 ( THQ-50C)

ER70S-6 ( THQ-50C)

Solid welding wire for gas shielded welding

GB/T8110 ER50-6

ISO 14341-A-G42 3C1 Z3Si1

AWS A5.18 ER70S-6

Chemical composition of the welding wire (mass fraction): %

Items | C | Mn | Si | S | P | Ni | Cr | Mo | V | Cu |

Standard value | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.03 | ≤0.50 |

Case of value | 0.08 | 1.50 | 0.89 | 0.012 | 0.013 | 0.03 | 0.02 | 0.002 | 0.003 | 0.11 |

X - Ray Detection: Grade II

Mechanical properties of deposited metal: (CO2)

Items | Tensile strengthRm/MPa | Yield strength Rel/Rp0.2 MPa | Elongation A/% | Charpy V-notch impact energy KV2(J)-30℃ |

Standard value | ≥500 | ≥420 | ≥22 | ≥27 |

Case of value | 560 | 450 | 26 | 108 |

Welding reference current : (DC +)

Welding wire diameter(mm) | 0.8 | 1.0 | 1.2 | 1.6 |

Welding current(A) | 50-180 | 70-230 | 80-350 | 120-500 |

Classification Society Certification:

Ship inspection agency | ABS | BV | CCS | DNV | GL | LR | NK | KR | CWB |

level of recognition | 3YSAH10 | SA3YMHH | 3YSH10 | ⅢYMS(H10) | 3YS | 3YSH15 | KSW53G(C)H10 | 3YSG(C)H10 | B-G49A3CG6 |

EU certification:

Certification body | CPD-CE steel structure certification |

Model | G42 3 C1 Z3Si1 |

| PRODUCT APPLICATION |

Some of our products have been applied to overseas key projects.

Electrode, SAW wire and flux of 600MPa Grade & 800MPa Grade

applied to hydro steel at Laos pumped storage power station

E6010 cellulose electrode Applied to the Ghana TEMA pipeline project in Africa successfully. It breaks the monopoly of Bohler cellulose electrode and won the bidding of oil pipeline Ghana tank project

| RELATED PRODUCTS |

| Welding Wire | Flux Cored Welding Wire |

| MORE >> | MORE >> |

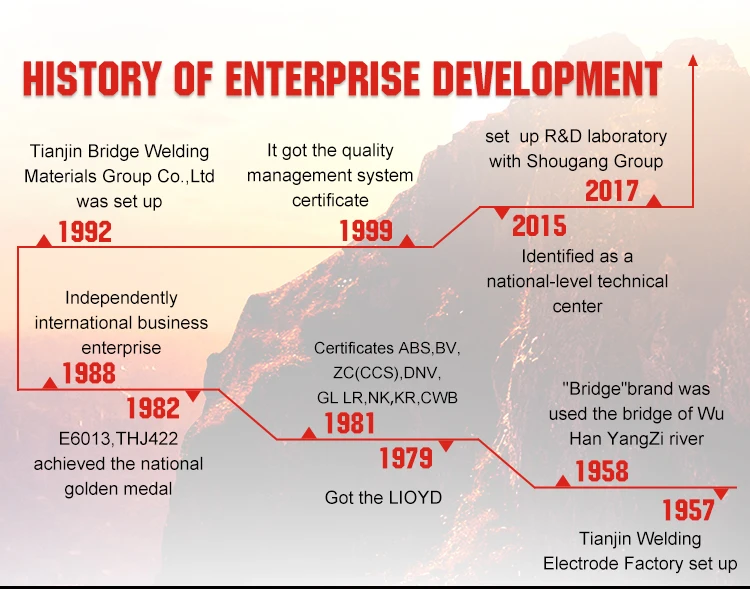

| ABOUT US |

Tianjin Bridge Welding Materials Group Co., Ltd., founded in 1957, is one of the largest welding consumables manufacturing enterprises in China. In the past half century, "BRIDGE " welding consumables sell well in more than 60 countries and regions. "BRIDGE”welding consumables has 4 categories, 500 types more,including covered electrodes (SMAW), solid wire/Rod (GMAW & GTAW), flux-cored wire/Rod (FCAW) and sub arc wire/strip & flux (SAW/ESW). They are for welding steel of non-alloy & fine grain steel, creep resistant & weatherproof steel, stainless steel, surfacing welding, cast iron, Ni & Ni-alloy steel, AI & Al-alloy steel, Cu & Cu-alloy steel and other special welding & cutting. Our products are widely used in construction, shipbuilding and offshore, land traffic and aerospace, boiler and pressure vessel, energy, household appliance, machinery manufacturing,military industries and many other fields.

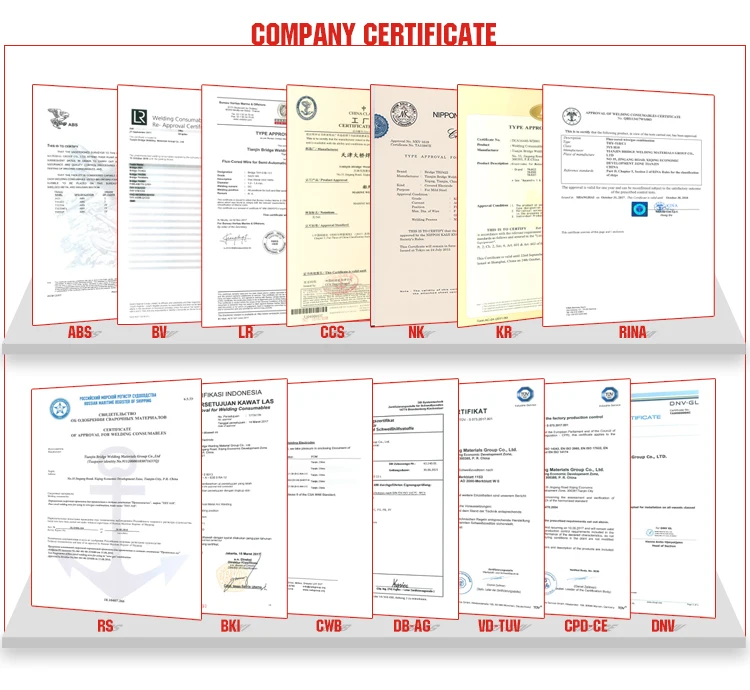

Keeping improvement and development for product technology and quality continually, which always make us the leader in welding consumables industry. Tianjin Bridge Welding Materials Group Co., Ltd. Passed ISO9001, ISO14001, OHSAS18001 and ISO5001 approvals. Our products of shipbuilding & offshore are approved by ABS, BV, CCS, DNV.GL, LR, NK, KR, RINA, RS, BKI and CWB. Main products are approved by CPD-CE, DB-AG and VD-TUV.

Our: Guiding Ideology- "People-oriented, pursuing sustainable development" Quality policy- "pursuing perfect quality, establishing a good corporation reputation, with excellent quality and service" Principle- "Customers' satisfaction is the first"

We are the professional and perfect partner

of yoursin welding consumables.

| F A Q |

Q: what is delivery time / lead time ?

A: 30 days

Q: what is your minimum order ?

A: 5000kgs

Q: what is your payment term ?

A: 1- 30% down payment for order confirmation, 70% before shipment.

2- 100% at sight LC

Q: can we visit your factory ?

A: yes you can at your free time.

-

Bridge Brand Carbon Steel welding wire without copper er70s-6 0.8mm 15kg mig CO2

-

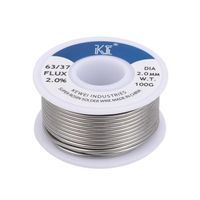

Tin solder wire rosin active core solder wire 63/37 60/40 40/60 0.8mm 1.0mm 1.2mm 2mm tin wire 25g 50g 100g 200g 250g wel

-

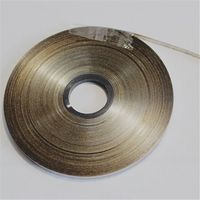

Nickel-based amorphous brazing foil BNi-2/BNi-3

-

FCAW cored vacuum welding wire E71T-GS E71T-1 carbon steel with MIG welding wire 0.8 1.0 1.2mm 1KG 5KG 15KG

-

Solder wire 500g 60 40 (0.5/0.6/0.8/1.0mm) High-purity tin wire for PCB SMD BGA rework soldering accessories

-

2021 new soldering tin, thermal conductivity 0.8mm welding wire manufacturing machine/

-

Electronic solder solder wire Sn63Pb37 Sn60Pb40 50g 100g 200g

-

brazing rod Phosphor copper BCuP-2 brazing rod

-

Premium Super Solder Wire

-

Hiclass solder wire 0.5mm 0.8mm 1.0mm 100g tin flux rosin active flux cored wire 60/40 SN60 Pb40 same Asahi quality

Other Products

-

$0.84 - $1.28 / kilogram

$0.84 - $1.28 / kilogram -

$1.18 / kilogram

$1.18 / kilogram -

$0.85 - $1.14 / kilogram

$0.85 - $1.14 / kilogram -

$400.00 / piece

$400.00 / piece -

$0.88 / kilogram

$0.88 / kilogram -

$750.00 / piece

$750.00 / piece -

$0.70 / kilogram

$0.70 / kilogram -

$0.96 / kilogram

$0.96 / kilogram -

$0.55 / kilogram

$0.55 / kilogram -

$0.90 / kilogram

$0.90 / kilogram