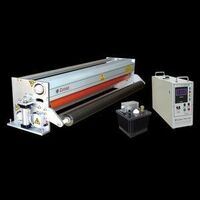

RY-cty4000 Corona treater film corona treater oil transformer

-

Supplier: Ruian Ruiyu Industrial Control Instrument Factory -

Region: Zhejiang, China -

Contact: Ms Sharry Zhao -

Price: $230.00 /set -

Min. Order: 1 set

| Warranty of core components: | 1 YEAR; | Operation Frequency: | 15-30Hz; |

| Packaging Detail: | Carton packing; | Core Components: | Engine; |

| Applicable Industries: | Machinery Repair Shops,Food & Beverage Factory,Printing Shops,Advertising Company,other; | Machinery Test Report: | Provided; |

| Condition: | New; | Product name: | corona treater oil tranformer; |

| Video outgoing-inspection: | Provided; | Single package size: | 48X32X32 cm; |

| Selling Units: | Single item; | Installation Way: | Vertical type 260x160mm; |

| Marketing Type: | New Product 2020; | Max Processing Width: | 2KW ≤1000mm; |

| Local Service Location: | None; | Brand Name: | RUIYU; |

| Single gross weight: | 9.5 KG; | After-sales Service Provided: | Online support,Video technical support; |

| Warranty: | 1 YEAR; | Place of Origin: | Zhejiang China; |

| Input Voltage and Frequency: | AC 220V±10%,50/60Hz; | Package Preview: | ; |

| Showroom Location: | None; | After Warranty Service: | Video technical support,Online support; |

| Key Selling Points: | High Productivity; |

RY-cty4000 Corona treater film corona treater oil transformer

Summary

Corona treater commonly as electric airsick ,electronic impact machine,electric discharge machining in packaging industry. In technically known as dielectric barrier discharge. Mainly used in Plastic film or plastic sheet products surface treatment, for these materials ink printing,composite,blown film,coating,adhesive,material modification,grafting,polymer,stretch film,paste processing before. In order to make the product surface has a stronger adhension force (a higher dyn coefficrent),to prevent the occurrence of the phenomenon such as printing materials color fade,composite paste is not strong,uneven coating leak adhesive in the process,affect the product quality,must shock corona treatment before.

Product Application

Applied in industries of plastic film blowing, printing, lamination, glue coating, coating cloth, digits jetting, paint spraying, suitable for all kinds of plastic film (such as PP,PE,PETP,OPP,PS,PA,etc.),aluminum foil, aluminum film plating paper and fiber.

Main Features

1) Controlled by microcomputer, the digital output display, easy to operate

2) Automatic phase-locked control technology, and with input short circuit, over-current protection functions.

3) Support the halt function caused by no materials and film cutting.

4) Support boot-up protection function.

| THE MAIN TECHNICAL PARAMETERS | |||||||

| Model | RY-CTY2000 | RY-CTY3000 | RY-CTG2000 | RY-CTB | RY-CTFY | RY-CTY4000X2 | |

| Input voltage and frequency | AC 220V 50/60Hz | AC 220V 50/60Hz | |||||

| Operation frequency(Hz) | 15-30 | ||||||

| The max output(KW) | 2 | 3 | 2 | 2 - 4 | 8 | ||

| The max processing width(mm) | Double-sided plastic film / Single-sided metal film |

1000 | 1300 | 1200 | 1000-1500 | 2500 | |

| Application Materials | PE,PP,PS,PETP,OPP,PA,PVC Plastic film and aluminum-plated steel,Laser film,Aluminum foil metallic film. | ||||||

| Transformer Type | Oil-immersed type | Dry type | Oil-immersed / Dry type | Oil-immersed type | |||

| Structure | Integrated type:Transformer is installed in the treater | Integrated type / Spilt type |

Spilt type:Transformer on the outside | ||||

| Weight(Kg) | 7.1 | 11.5 | 18 | 22 | 4.35 | 38 | |

| Dimensions(mm) | 390 x 235 x 225 | 410x305x225 | 595 x 182 x 350 | 300 x 205 x 202 | 450 x 350 x 1120 | ||

easy damage eliminator.

perpendicular to electrostatic objects.The closer distance is, the better electrostatic effect is.

-

Corona Generator HW-2003G and Corona Station for Blown Film Machine Corona Treater

-

Manufacturer Corona Treater Made in China

-

Thermal splicing press for spindle belt/splicer/flat belt thermal splicer

-

Plastic film corona treatment machine

-

New Product High Efficiency 4 Axis 5 Bulk Diamond Plant Dispensing Machine

-

EVA 3D school bag printing machine

-

Rubber & Plastic Dispersion Kneader

-

High quality Italian socket welding machine for plastic pipes IAM-S./200-630

-

50 tons of FRP light pole hydraulic pultrusion machine

-

Mobile film surface corona treater

Other Products

-

$488.00 / set

$488.00 / set -

$2999.00 / set

$2999.00 / set