50 tons of FRP light pole hydraulic pultrusion machine

-

Supplier: Guangdong Renda Intelligent Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Chen Charlie -

Price: $20500.00 /set -

Min. Order: 1 set

| Marketing Type: | normal product | Core Components Warranty: | 1 year |

| port: | Shenzhen/Guangzhou | Mechanical test report: | if |

| place of origin; place of origin: | Guangdong, China | payment terms: | letter of credit, wire transfer |

| brand: | Renda | After-sales service provided: | Free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, online support, video technical support |

| Main selling point: | automatic | Applicable industries: | manufacturing plant |

| Warranty: | 1 year | Video external inspection: | if |

| After Warranty Service: | Video technical support, online support, on-site maintenance and repair services | Local service location: | not any |

| Packaging Details: | Packing: The machine is surrounded by plastic film, and the bottom of the machine is supported by a wooden pallet, or packed with the surrounding plastic film and wooden box. | Health status: | new |

| Showroom location: | not any | Supply capacity: | 30 sets per month |

| Core components: | PLC, bearing, motor, gear, pump | Packaging Preview: |

01. Advantages of Renda pultrusion machine

- The pultrusion machine adopts an advanced programmable controller system, and the electrical system and hydraulic system are assembled with world-renowned brand components (such as standard electrical components, hydraulic oil pumps, solenoid valves, electro-hydraulic valves, pressure valves, etc.).

- Select high-quality materials, and use CNC and other advanced manufacturing processes to process mechanical parts to ensure the straightness and running accuracy of the machine, and ensure the smooth running of the machine

- The frame of the fuselage is designed and manufactured with thickened steel to ensure that the rigidity of the machine does not yield when the large tonnage is pulled.

- The line and circuit cables of the whole machine are connected according to the European CE standard, with clear markings for easy inspection and maintenance

- The design of the whole machine production line well meets the requirements of the FRP pultrusion process, ensuring that users feel smooth when using the Renda pultrusion machine

- The equipment application failure rate is low and the service life is long.

02. List of pultruder models

- Hydraulic Reciprocating Pultruder Model List-

| Do not. | Model |

Rally.Max (kN) |

Clamping force.Max (kN) |

Traction speed (mm/min) |

Reciprocating travel (mm) |

Window size (WxHxL)

|

Clamping cylinder stroke (mm) |

| 1 | RDLJ-Y6T | 60 | 60 | 0.1~1.2m/min | 600 | 600x200x400 | 200 |

| 2 | RDLJ-Y10T | 100 | 100 | 0.1~1.2m/min | 600 | 600x300x400 | 250 |

| 3 | RDLJ-Y15T | 150 | 150 | 0.1~1.2m/min | 600 | 800x350x500 | 250 |

| 4 | RDLJ-Y20T | 200 | 200 | 0.1~1.2m/min | 600 | 900x400x500 | 250 |

| 5 | RDLJ-Y30T | 300 | 300 | 0.1~1.2m/min | 600 | 1000x500x600 | 250 |

| 6 | RDLJ-Y40T | 400 | 400 | 0.1~1.2m/min | 600 | 1200x600x800 | 250 |

| 7 | RDLJ-Y50T | 500 | 500 | 0.1~1.2m/min | 600 | 1500x600x1000 | 250 |

| 8 | RDLJ-Y60T | 600 | 600 | 0.1~1.2m/min | 600 | 1500x600x1000 | 250 |

|

attention: 1. This is just the general model, if your resin system isepoxy or polyurethane, may be different from the general model, or your other size requirements, please tell me your detailed requirements, we will confirm the machine model with you. 2. If you have other larger pulling and clamping force requirements, please consult us, we also do80T and 100Tforce, and even larger pultruders. |

|||||||

03. Introduction to the process flow of pultrusion production line

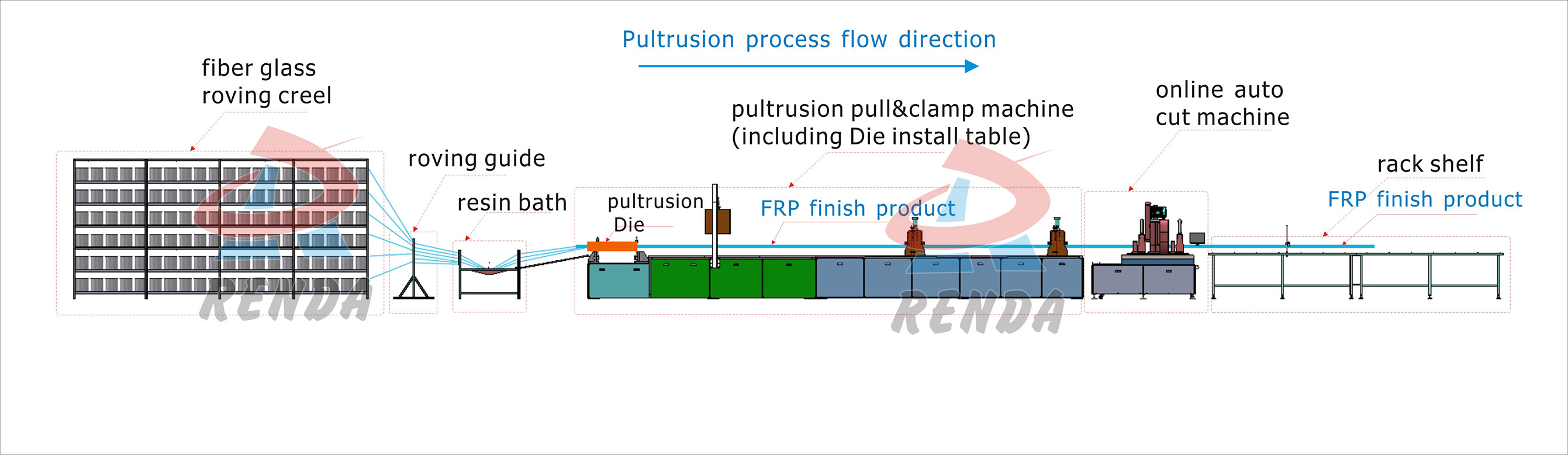

- Layout drawing of pultrusion production line process -

Note-1:

In fact, as"Pultrusion production line process layout display",The entire pultrusion production line consists of:

1). roving creel,

2). Roving Guide,

3). resin bath (or injection machine, if the mold you are using is an injection mold),

4). Pultrusion dies and preforms,

5). pultrusion machine,

6). online automatic cutting machine,

7). Finished FRP product rack.

04. Pultrusion die

Note-2:

Note-2:

In addition to the pultrusion machine production line, we at Renda also specialize in designing and manufacturing various pultrusion dies, some die types and FRP profiles, as shown in the picture above, we provide a full range of pultrusion die production services: including dies, preforms, heat transfer tools . We believe we can provide you with a perfect set of pultrusion dies to produce the best FRP products for you.

05. Photo to know more about our company

-

Corona Generator HW-2003G and Corona Station for Blown Film Machine Corona Treater

-

Manufacturer Corona Treater Made in China

-

Thermal splicing press for spindle belt/splicer/flat belt thermal splicer

-

Plastic film corona treatment machine

-

New Product High Efficiency 4 Axis 5 Bulk Diamond Plant Dispensing Machine

-

EVA 3D school bag printing machine

-

Rubber & Plastic Dispersion Kneader

-

High quality Italian socket welding machine for plastic pipes IAM-S./200-630

-

Mobile film surface corona treater

-

Low temperature plasma treatment machine Corona plasma treatment equipment Plasma surface treatment machine