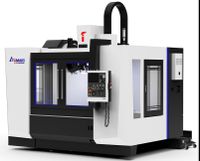

SKYFIRECNC SVM-2VMC Mini Industrial CNC Machining Center

-

Supplier: Yantai Lofty Mountain Machinery Manufacturing Co., Ltd. -

Region: Shandong, China -

Contact: Ms. Lulu Lv -

Price: $14000.00 /unit -

Min. Order: 1 unit

| Place of Origin: | Shandong China; | Voltage: | 220V/380V; |

| 4/5th axis: | optional; | Selling Units: | Single item; |

| Package Preview: | https://sc02.alicdn.com/kf/HTB1vAxaSMDqK1RjSZSy761xEVXaI.png_640x640.png; | 2nd spindle: | optional; |

| Weight: | 850KG; | After-sales Service Provided: | Online support,Video technical support,Free spare parts; |

| Single package size: | 172X122X190 cm; | Enclosure: | full enclosure; |

| Spindle driving: | AC SERVO; | Brand Name: | SKYFIRE CNC; |

| Ball screws: | C3 class; | CNC controller: | ADTECH CNC9650 5-axis CNC controller; |

| Type: | Vertical; | Auto tool changer: | 12-tool; |

| 3-axis rails: | HIWIN linear rails; | Single gross weight: | 980 KG; |

| Power(W): | 5000; | Dimension(L*W*H): | 1500*950*1700MM; |

| Condition: | New; | Warranty: | 1 year; |

| Certification: | CE; | Coolant system: | included; |

| Package Type: | Composite Plywood Crate LWH 172*122*190 CM; | Axis driving: | AC SERVO; |

SVM-2VMC is a professional Mini Industrial CNC machining center. It’s of compact size but made as a standard industrial level VMC. It's equipped with AC SERVO driving BT30 spindle, full linear ways and full AC SERVO 3 axis motion system.

SVM-2VMC comes with 5 axis industrial CNC controller and additional operation panel. It supports 5-AXIS ALIGN machining and RIGID TAPPING applications. 12-TOOL Auto Tool Changger is installed for auto operation. Live Measurement System & Tool Measurement System can also be installed for super pricision machining works. Many CUSTOMIZED OPTIONS like high speed spindle, through spindle cooling, WIFI remote control device and specified controller etc. can be optional.

**Please ask for SVM-2VMC series datasheet for more information**

SVM-2VMC can handle all materials from Plastic, Aluminium, Brass, Steel, Stainless Steel to Taitanium. It's a real industrial level CNC machine to do precision machining works. Typical machining tolerance is <0.01mm.

SVM-2VMC is excellent for personal machinists, metal workshops, R&D departments, CNC training education and small production factories. Any special requirements please inquire to us directly.

Strong aging-treated cast iron frame to prevent losing accuracy by time

HIWIN™ High precision class linear ways and C3 class ground ballscrews for all 3 axis / Z axis enhanced with heavy duty roller type linear ways

Up to 10000RPM BT30 spindle unit / AC SERVO driving / support rigid tapping

AC SERVO motor system for all 3 axis / Rapid, smooth and never lose step

5-axis align controller enable complex machining works / Compatible G code system / Full English operation&programming manuals

Industrial style full enclosure / Chip drand coolant system built in cabinet stand / heavy ast iron stand available

Unique ptional 2nd engraving spindle for precision 3D engraving works

High accuracy, Zero backlash 4th/5th axis sets options enable complex workpiece machining but with low cost.

Auto tool changer has been included in Standard configurations

DIMENSIONS | |

Table Size: | 760mm×240mm / 30”×9.8” |

Table Slots: | 5×14mm Slots |

Travel Range (X Y Z): | 420mm×250mm×400mm / 16.5”×10”×15.7” |

MAX Spindle Nose to Table: | 450mm / 17.7” |

MIN Spindle Nose to Table: | 50mm / 2” |

Spindle Center to Column: | 280mm / 11” |

MONTION FEATURES | |

Max On Table Weight: | 100Kgs |

Max Feed Rate: | 10MPM / 393IPM |

Positional Tolerance: | 0.005mm |

Repeatable Tolerance: | ≤0.003mm |

XYZ Traveling Tolerance: | ≤0.01mm /200mm |

1st Spindle Radio/Axial Run Out: | ≤0.008mm at 200mm |

SPINDLE CONFIGRATIONS | |

1st Spindle Taper: | BT30 |

1st Spindle Speed: | max 10000RPM |

1st Spindle Driving System: | 2.2kw AC SERVO Motor System (3.7kw optional) |

1st Tool Changing: | Air drive power drawbar |

ATC System: | 12-tool ATC |

MOTION PARTS | |

3 Axis Driving: | AC SERVO driving System |

3 Axis Motion: | HIWINTM H Class LINEARS for all 3 axis |

Ballscrews: | C3 Class Ballscrews |

Bearings: | P4 Class Bearings |

ELECTRONICS | |

CNC Controller: | ADTECH CNC9650 5-axis industrial CNC controller |

Axis Driving Power Supply: | AC power supply |

Relay Output: | Integrated and expandable |

POWER REQUIREMENTS | |

Power Input: | 210-240VAC 50/60HZ Single Phase 220/380VAC 3-phase optional |

Power Consumption: | Typical 5kw |

MISCELLANEOUS FEATURES | |

Machine Shell: | Full closed enclosure |

Spindle Box Balancing: | 2x Nitrogen springs |

Lubrication: | AUTO centralization lubrication |

Work Light: | LED work light |

Coolant System: | Coolant system with swarf drawer integrated |

Mist Cooling System: | optional |

MPG: | optional |

Air Blow Gun: | included |

Air Source: | >0.5Mpa |

Tooling & Accessories: | optional (refer to detailed tooling lists) |

Other CNC Control System: | optional |

OVERALL FEATURE | |

Overall Dimensions(L*W*H): | LWH 950*1500*1700mm |

Net Weight: | 850kgs |

Package Dimensions(L*W*H): | LWH 172*122*190cm |

Gross Weight: | 980kgs |

Package Type: | Composite Plywood Case |

5-Axis Applications

Please send us message for more information.

Or you can also visit our website and send us email directly.

Find us on Instagram and Youtube by searching "skyfirecnc" .

Or add our Skype: skyfirecnc

We will be happy to help all of your questions anytime!

-

Vertical machining center cnc milling machine VMC850 cnc milling machine

-

High-precision five-axis CNC milling machine CNC single-sided milling machine HD-QC41

-

Taiwan Cnc Vertical Machining Center Vmc855 VMC850 Cnc Milling Machine

-

Chine Teast Export supply of VMC855/850 dental cnc milling machine casting

-

Very popular drilling and tapping center high precision FANUC system for machining precision parts

-

Gantry Milling Machines & Lathes

-

CNC Router, CNC Automatic Machining Centers

-

Metal Processing Vertical CNC Machine

-

Universal Gantry Machining Centers

-

High Accuracy CNC Vertical Machine Center