gas chromatograph mass spectrometer

-

Supplier: Dongguan Haida Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Lisa Zhong -

Price: $5800.00 /set -

Min. Order: 1 set

| Port: | shenzhen; | Column temperature setting accuracy: | 0.1℃; |

| Brand Name: | HD; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,gas chromatograph; |

| Supply Ability: | 30 Set/Sets per Month gas chromatograph; | Packaging Detail: | Each set protected with resin fiber and PP film, then put into Strong wooden case with operation manual and video inside.; |

| Program heating order number: | 7; | ECD Detector compensation Gas Type: | 5% Methane/Argon or nitrogen; |

| Program heating rate: | 0.1~120℃/min(Incremental 0.1℃); | FID Minimum detectable limit: | ≤2.5pgC/s [n-C16]; |

| TCD Maximum operating temperature: | 400℃; | FPD Selective: | 105gS/gC,106gP/gC; |

Automatic sampling gas chromatograph

Automatic sampling gas chromatograph is used for quantitative and qualitative analysis to determine the physical and chemical constants such as the distribution coefficient, activity coefficient, molecular weight and surface area of the sample in the fixed phase. An instrument for analyzing the components of a mixed gas.

Application industry

1. Analysis of dissolved gas in transformer oil;

2. Analysis of ethylene oxide in medical devices.

3. Analysis of coke oven gas;

4. Pesticide residue analysis;

Alcohol analysis in blood; 5.

6. Analysis of natural gas and liquefied gas;

7. Indoor environment TVOC analysis;

8. Analysis of liquor components;

9. High purity gas analysis;

10. Detection of solvent residue of packaging materials.

Performance characteristics

1. Inlet flow rate, chromatographic column load airflow, detector gas flow, complete EPC control

Micro-channel Air Circuit Integrated Board

All-imported miniature proportional valves and flow/pressure sensors Automatic temperature compensation ensures accurate flow and pressure control to 0.01Psi

2. Industry-Leading detector design

All detectors are high-precision electronic flow/pressure control

Fit and fill column and capillary column Special ceramic treatment of the enlarged plate, in the humid season is always stable Automatic ignition, hydrogen leak automatic protection function, safe and reliable

3. Automatic ignition, hydrogen leakage automatic protection function, safe and reliable

4. Accurate furnace temperature tracking design

5. Independent Heating small column box In the multi-column chromatographic system, the temperature of different columns can be set respectively, so as to achieve the best separation effect of each column.

6. Fully imported Valve configuration system Up to 8 valves (four-pass valve, six-pass valve, ten-pass valve and liquid injection valve optional); Automatic control, sequence operation;

7. Precision temperature control of the heating furnace Furnace internal control accuracy less than 0.01°c

The temperature difference between the internal points is not more than the °c

Rapid heating and cooling, the highest program heating speed: 120℃/min, balance time 10 seconds, cooling time 300°c~50°c 6 minutes Absolute control of the temperature accuracy (with the actual temperature difference is less than 0.3C)

8. Pneumatic cutting technology for the convenience of implementation

Multi-dimensional chromatographic function to complete the separation and analysis of complex samples It can realize the inverse blowing function of chromatographic column to save the analysis time and cycle greatly.

9. Advanced Power Distribution Management shunt A 3000 watt UPS can provide 10 units of normal power 2250 watts/set of GC stable working power supply

10. Automatic Feed 8-bit automatic injection device (optional Agilent 7683/7693 liquid automatic injection)

11. With Automatic online detection function

Technical indicators

Column temperature Box | ||||

Furnace Size | 28×30×18cm | |||

Temperature control Range | Above room temperature5℃~450℃;Using liquid nitrogen cold traps:-80℃~400℃;Using dry ice traps:-55℃~400℃ | |||

Temperature setting accuracy | 0.1℃ | |||

Maximum program heating rate | 120℃/min | |||

Maximum once method run time | 999.99min | |||

Program heating order number | 7 | |||

Program heating rate | 0.1~120℃/min(Incremental 0.1℃) | |||

Operation Column loss compensation (dual channel) | ||||

Heating Zone | ||||

6 independent control Heating zone control (excluding furnace temperature, two inlet, two detectors, two auxiliary heating area auxiliary heating zone maximum operating temperature ) | ||||

| 300℃ | |||

Detectors | ||||

Hydrogen Flame Ionization detector FID | ||||

Maximum operating temperature | 450℃ | |||

Minimum detectable limit | ≤2.5pgC/s [n-C16] | |||

Dynamic linear range | ≥107(±10%) | |||

Data acquisition frequency | The highest: 100Hz | |||

Thermal conductivity cell detector TCD | ||||

Maximum operating temperature | 400℃ | |||

Minimum detectable limit | <400pg C3H8/ml(He) | |||

Dynamic linear range | 105(±5%) | |||

data acquisition frequency | The highest: 100Hz | |||

Flame photometric detector FPD | ||||

Maximum operating temperature | 250℃ | |||

Minimum detectable limit | <4pgC/sec,<1pg P/sec | |||

Selective | 105gS/gC,106gP/gC | |||

Dynamic linear Range | >103S,>104P | |||

Electronic Capture Detector ECD | ||||

Maximum operating temperature | 400℃ | |||

Detector compensation Gas Type | 5% Methane/Argon or nitrogen | |||

Minimum detectable limit | <0.01Ppg/s lindane | |||

Dynamic linear range | >5×1055 | |||

data acquisition frequency | 100Hz | |||

Radioactive sources | <12mCi 63Ni | |||

Nitrogen and phosphorus detectors NPD | ||||

Maximum operating temperature | 450℃ | |||

Minimum check out limit | <0.2 pg N/sec,<0.2 pg P/sec | |||

Dynamic linear Range | 105N,105P | |||

Minimum detection limit | <0.3pg C/Sec | |||

The above detectors are suitable for filling column and capillary column | ||||

Optional configuration | ||||

Anti-control software | Automatic Feed b6891n | |||

Our company Introduction:

HAIDA INTERNATIONAL is a professional manufacturer of various kinds of testing equipments over 24 years. HAIDA products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and applicable to all scientific research units, quality inspection institutions and academic fields.

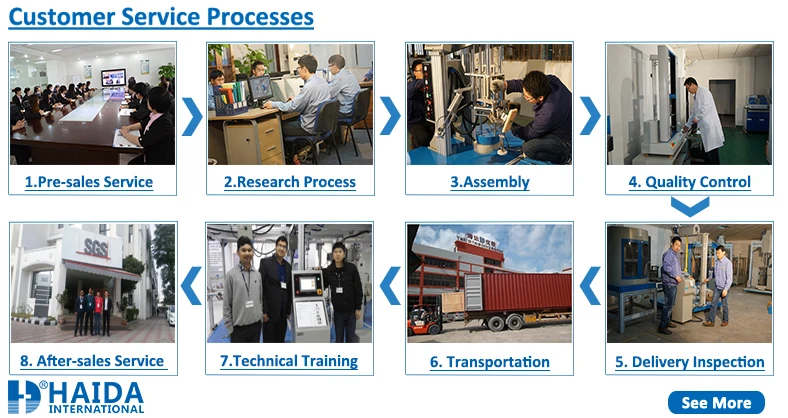

Haida Equipment Service:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-con.

Onsite Service:

1.Device installation; 2.Equipment Operation Test Technology training;3.Equipment Calibration;4.Daily maintenance and maintenance of equipment

Free technical training for visiting factories

24-hour Online contact

Free software upgrades

Free information:

1.Product Instruction;2.Product operation instruction/video;3.Experiment Test (test application, test report)

Device Problem Handling:

1. Social media 24 hours online communication;2. Mail Seamless Docking;3. Video Conferencing;4. Artificial free door-to-door service

Packaging & Shipping

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case.

Why choose us?

1. Considerate Service Different countries plugs, manually change the-voltage from 110V to 220V, insurance indicator.

2.Excellent After sale Service:

12 months warranty. Besides, we can help you to repair your problem controller freely, Free replacement parts, even it's not from our factory's. What you need to do is to send us the controller.We can offer operation video and English operation muanual. We can provide video-con

-

HUGEROCK G71M High Performance GNSS Surveying Instrument GPS Drone RTK Industrial Rugged Android Tablet 7 Inch

-

SK F TKSA 51 laser axis alignment system

-

Portable underwater terrain survey won the bid for the price of the unmanned marine vehicle iBoat BS1 unmanned surface vehicle

-

German Bruker Handheld Spectrometer/Handheld Alloy Analyzer S1 TITAN/TRACER 5g

-

New design drinking water and swimming pool water quality analysis kit / water quality analyzer test kit

-

Testo 550s Testo 557s Smart Kit with 2 Digital Multimeter Metering Valves

-

Newest Gnss Receiver Measuring Instruments Gps Gnss Hi-Target Vrtk V5 Gnss

-

New Ivoclar Vivadent Programs P710

-

Smart Testo 557s Smart Kit with 2 digital multimeter valves

-

SunNav S26 GPS RTK Other Test Instruments GPS rtk 970 E91 Geographic Equipment S26 RTK GNSS

Other Products

-

$2000.00 / piece

$2000.00 / piece -

$4000.00 / set

$4000.00 / set -

$1200.00 / set

$1200.00 / set -

$800.00 / set

$800.00 / set -

$4200.00 / set

$4200.00 / set -

$12000.00 / set

$12000.00 / set