High-tech Factory Custom High Precision Aluminum Die Casting Case Spare Motor Parts

-

Supplier: Dongguan Mingyi Hardware Products Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Victor Xu -

Price: $3.20 /piece -

Min. Order: 1 piece

| Brand Name: | motor parts; | Technology: | die casting parts; |

| Model Number: | motor spare parts; | Delivery Time: | 10-25 Days; |

| MOQ: | 1PCS; | Tolerance: | +/-0.02mm; |

| Packaging Detail: | Bubble Bag, Carton, Pallet/Wooden Box or as your demands, hydraulic construction machinery china spare bicycle auto parts lamp motorized tricycles motorcycles motor case housing cover.; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| Supply Ability: | 100000 Piece/Pieces per Month motors parts; | Place of Origin: | Guangdong China; |

| Size: | Customer's Requst; | Port: | Yantian Shenzhen; |

| Application: | Motor Parts; | Surface: | Anodized or Painting; |

| Finish: | Silver Color Anodized; | Material: | Aluminum; |

High-tech Factory Custom High Precision Aluminum Die Casting Case Spare Motor Parts

| Material | Aluminum alloy ADC12, ADC10, A360, A380, A356, iron Magnesium alloy AZ91D, AM60B, Zinc alloy ZA3#,ZA5#,ZA8# |

| Processing Craft | Drawings→ mould making → die casting →rough machining → CNC machining →surface treatment →product checking→ packing →delivery |

| Tolerance | ± 0.02mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating, Sandblasting, Passivation, Spray painting, Etc. |

| Quality Assurance | ISO9001:2015 Certified, SGS Certification |

| Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance. 2.Third Party inspection available upon requirement. |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Quality Guarantee | Two years |

| Features & Advantage | 1.High machining accuracy, the flatness within 0.1mm. 2.High strength and not easy to deform, has good electrical and thermal conductivity. 3.High finish appearance, smooth surface roughness is Ra1.6 after machining. 4.Pass Salt Spray Test with 144 Hours. |

| Standard | 1.Aluminum alloy : ISO3522-84, ASTMB85-96, ASTMB597-98 2.Magnesium alloy : ISO/DIS16220-1999, ASTMB93/B93M-98,JISH2222-1991 3.Zinc alloy: ISO301-1981, ASTMB86-98, ASTMB240-98, ASTMB327-98 |

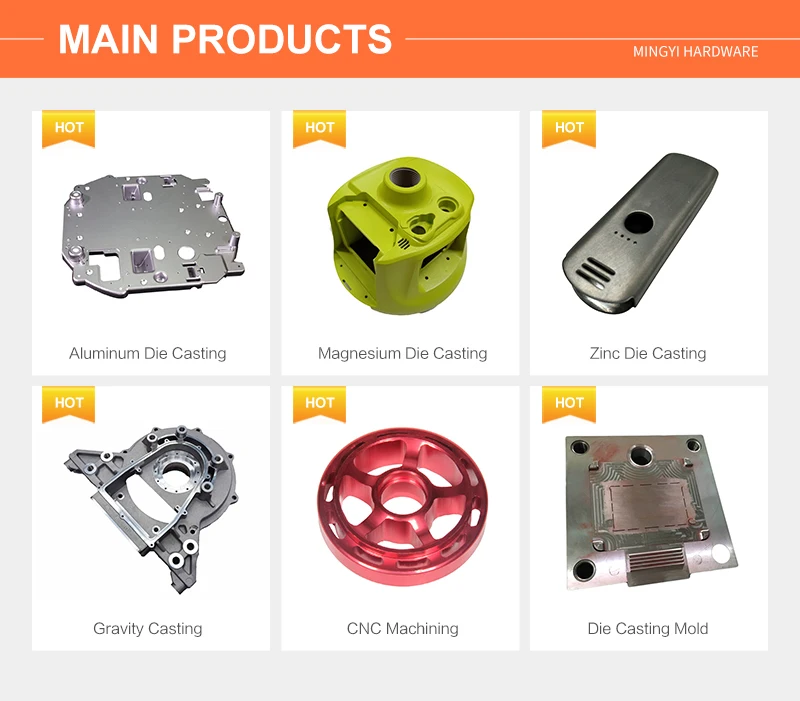

Dongguan Mingyi Hardware Products Co., Ltd. is a factory that professionally design and produce magnesium, aluminum, zinc alloy die casting, gravity casting, aluminum profiles, and CNC machining. It provides all-round production services from the design and development of mould to the forming and post-processing of die-casting products and surface treatment. The products are mainly used on 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment and so on. It is exported to Europe,America and Southeast Asia.

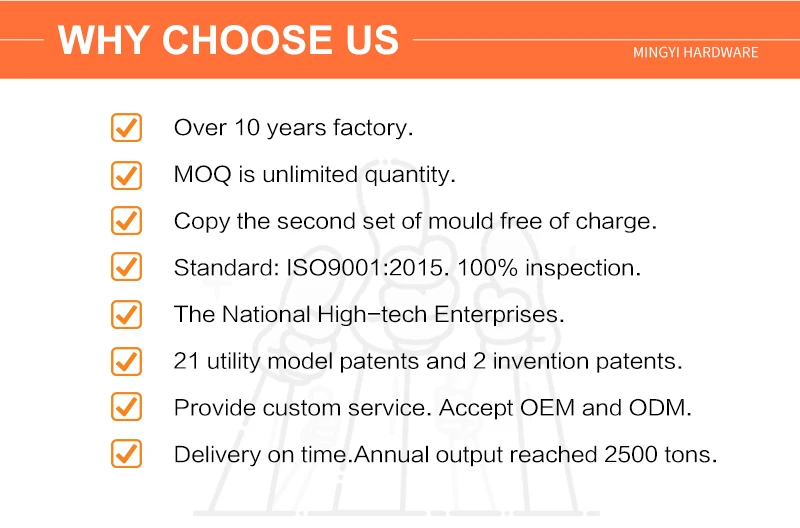

The company was founded in 2010, has 10 years’ experience about development and manufacture management, It has more than two dozen patented technologies (including two invention patents) and was recognized as a national high-tech enterprise in December 2017, We have obtained ISO9001:2015 Certificate in May 7th 2012.

Our company's production workshop consists of mould department, die-casting department, processing department, CNC department, paint department, etc. It has 12 professional die design engineers, senior mould making technicians, die-casting engineers, and CNC programmers. The quantity of production workers can be reach to two hundred.

Not the best, only better! We hope we’ll be the one of the hardware casting specialist. Welcome to pay a visit to our company.

-

QZL-220 Wholesale Price High Quality Aluminum Wire Durable Enameled Aluminum Enameled Wire Different Colors

-

Mortar spraying machine rotor and stator diameter 140mm height 390mm

-

BISON 5Kw generator 5Kva 5000W generator set stator

-

Axial Flux Stator 100 KW/Axial Stator Turn

-

18P silicon steel sheet brushless motor core BLDC coated core

-

Ye3 Ye4 motor stator and rotor

-

J201/J204/J164 High Copper Graphite Custom Carbon Brush Generator Carbon Brush

-

755 series electroplated steel motor fixed installation seat machine clip seat support bracket 775 DC motor bracket U-type

-

Electric bicycle ebike 750W high speed gear motor parts stator winding resistance

-

SWITCH coppr hook type 10 segment, China factory competitive price OD15.2*ID5*H14.2

Other Products

-

$0.90 - $1.20 / piece

$0.90 - $1.20 / piece -

$0.90 / piece

$0.90 / piece -

$1.00 / piece

$1.00 / piece -

$2.38 / piece

$2.38 / piece