High Precision LED Lighting Accessories Power Tool Parts Die Casting Aluminum Lampshade

-

Supplier: Dongguan Mingyi Hardware Products Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Victor Xu -

Price: $1.20 / 1 - 99 pieces

$1.00 / 100 - 999 pieces

$0.90 / >=1000 pieces -

Min. Order: 1 piece

Product details

| an examination: | 100% inspection | Drawing format: | PDF/CAD/3D/STP/AI |

| Casting tolerance: | +/- 0.02mm | Certification: | ISO9001:2015 |

| application: | LED Lighting Accessories | Packaging Details: | Bubble bags, carton boxes, pallet wood boxes or according to your requirements, die-cast aluminum. |

| Packaging Preview: | Surface treatment: | spray paint | |

| Custom Support: | OEM | Minimum order quantity: | 1 |

| brand: | Power tool parts cast aluminum | Material: | aluminum |

| Supply capacity: | 1,000,000 pieces of cast aluminum per month | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Processing process: | CNC finishing process | place of origin; place of origin: | Guangdong, China |

| model: | Power tool parts cast aluminum | port: | Shenzhen |

| color: | picture |

High Precision LED Lighting Accessories Power Tool Parts Die Casting Aluminum Lampshade

Product Description

| Material | Aluminum alloy ADC12, ADC10, A360, A380, A356 Magnesium alloy AZ91D, AM60B Zinc alloy ZA3#, ZA5#, ZA8# |

| Processing technology | Drawing→Mold Making→Die Casting→Roughing→CNC Machining→Surface Treatment→Product Inspection→Packaging→Delivery |

| tolerant | ± 0.02mm |

| surface treatment | Electroplating, chrome plating, zinc plating, nickel plating, electrophoresis, anodizing, polishing, powder coating, sandblasting, passivation, painting, etc. |

| quality assurance | ISO9001:2015 certification, SGS certification |

| an examination |

1. Internal casting: 100% inspection of critical dimensions; 100% appearance. 2. Third party inspection is available upon request. |

| Main Test Facility | 3D measuring instrument,Salt spray test chamber, dynamic balance detector, pneumatic testing |

| quality assurance | two years |

| Features and Benefits |

1. High machining accuracy, flatness within 0.1mm. 2. High strength, not easy to deform, with good electrical and thermal conductivity. 3. The surface finish is high, and the surface finish after processing is Ra1.6. 4. High machining precision and seamless assembly structure. 5. The appearance has no particles, no spots and no paint peeling. 6. Smooth appearance and corrosion resistance. 7. Passed 96 hours salt spray test. |

| standard | 1. Aluminum alloy: ISO3522-84, ASTMB85-96, ASTMB597-98 2. Magnesium alloy: ISO/DIS16220-1999, ASTMB93/B93M-98, JISH2222-1991 3. Zinc alloy: ISO301-1981, ASTMB86-98, ASTMB240-98, ASTMB327-98 |

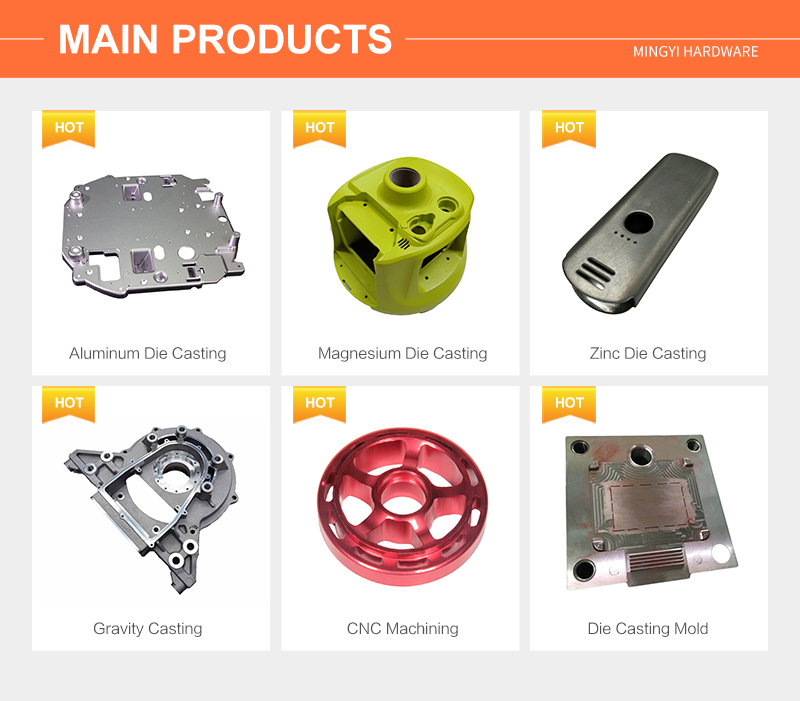

main products

VIEW MORE

You may like

-

5800 Chainsaw Ignition Coil Wholesale Wholesale 5200 Chainsaw Spare Parts Ignition Coil

-

All kinds of Dongcheng electric tool carbon brushes

-

1 607 014 176 Electric tool angle grinder parts carbon brush GWS7-115, 6X10X17MM

-

35.5"/24" Inch Small Portable Chainsaw for Chainsaw Wood Cutting Milling Sawhorse

-

BS2-20/2-22/2-24/2-26 power tool spare parts

-

Bosch GWS6-100 Double Insulated Angle Grinder Armature China

-

New electric piston pump GR smartcontrol 490 495 PC Pro airless paint sprayer

-

Various models and sizes for Bosch Carbon Brush Power Tool Carbon Brushes

-

cement scraper gypsum putty scraper

-

All Power Tools Electric Motor Carbon Brush Drill Bit Screwdriver Bemoliton Hammer 44A

Other Products

-

$0.90 / piece

$0.90 / piece -

$3.20 / piece

$3.20 / piece -

$1.00 / piece

$1.00 / piece -

$2.38 / piece

$2.38 / piece