Factory customized zinc die-casting electroplating mount micro projector bracket stand

-

Supplier: Dongguan Mingyi Hardware Products Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Victor Xu -

Price: $1.00 /piece -

Min. Order: 1 piece

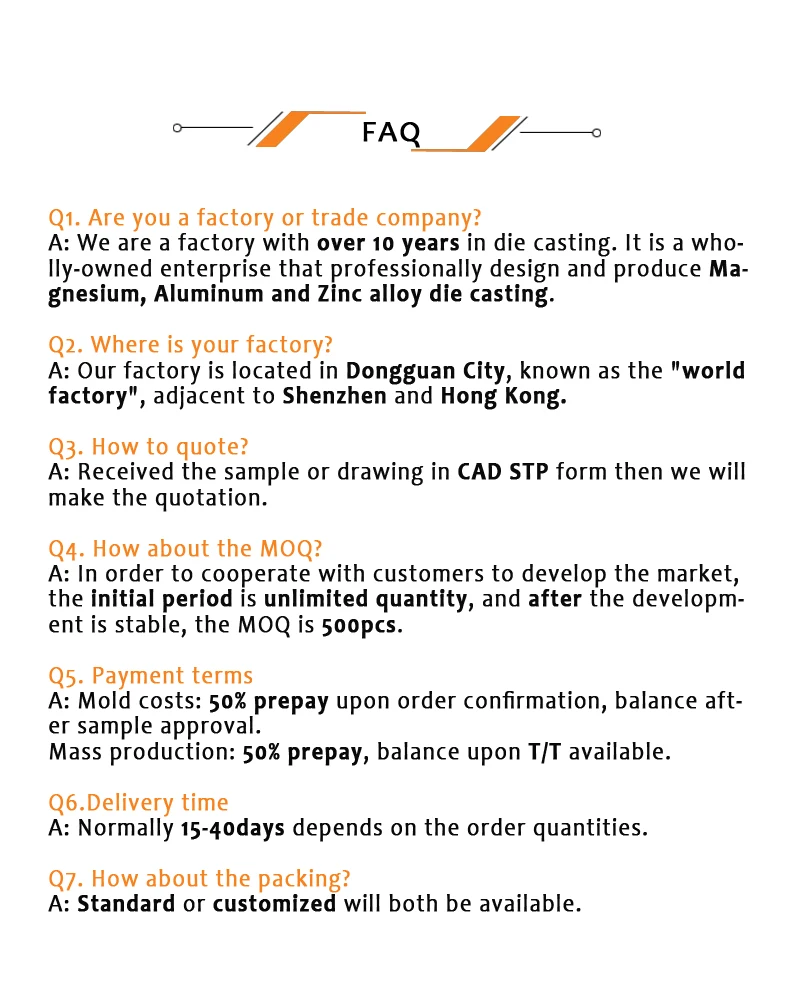

| Color: | Customized; | charging time: | 12 hours; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; | Size: | Diameter36mm; |

| LED Light Source: | White; | range: | 5M; |

| Port: | shenzhen; | Product name: | zinc die-casting electroplating mount micro projector bracket; |

| certificate: | ISO9001:2008; | Surface Treatment: | electroplating; |

| Supply Ability: | 20000 Piece/Pieces per Month projector mount; | Place of Origin: | Guangdong China; |

| Packaging Detail: | Carton packing, bubble bag for inner packing projector bracket.; | Model Number: | zinc die-casting; |

| Type: | Projector Mount; | Brand Name: | Mingyi projector bracket; |

| Processing: | Making Mold, Die casting,Machining,Surface treatment; |

Factory customized zinc die-casting electroplating mount micro projector bracket stand

Material | Aluminum alloy ADC12, ADC10, A360, A380, A356 |

Processing Craft | Drawings→ mould making → die casting →rough machining → CNC machining→surface treatment →product checking→ packing →delivery |

Tolerance | ± 0.02mm |

Surface Treatment | Chrome Plating, ZincPlating, Nickel plating, Electrophoresis,Anodization,Polishing,Powder coating,Sandblasting,Passivation,Spray painting, Etc. |

Quality Assurance | ISO9001:2015 Certified, SGS Certification |

Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appearance. |

Mainly Testing Facility | Three-dimensional measuring instrument, Salt spray test box, Dynamic balance detector, Pneumatic detection |

Features & Advantage | 1.High strength and not easy to deform, has good electrical and thermal conductivity. 2.High finish appearance,smooth surface roughness is Ra1.6 after machining. 3.The machining precision is high and the assembly structure is seamless. 4. Pass Salt Spray Test with 96 Hours. 5.Pass Adhesion Cross-Cut Test and 3M Glue Test. |

Standard | 1.Aluminum alloy : ISO3522-84, ASTMB85-96, ASTMB597-98,JISH2118:2000, JISH5302:2000 |

1 Over 10 years factory.

2 MOQ is unlimited quantity.

3 Copy the second set of mould free of charge.

4 Standard: ISO9001:2015. 100%inspection.

5 The National High-tech Enterprises.

6 21 utility model patents and 2 invention patents.

7 Provide custom service.Accept OEM and ODM.

8 Delivery on time. Annual output reached 2500 tons.

Dongguan Mingyi Hardware Products Co., Ltd. is a wholly-owned enterprise that professionally designs and produce Magnesium, Aluminum, Zinc alloy die casting and aluminum profiles. It provides all-round production services from the design and development of mould to the forming and post-processing of die-casting products and surface treatment. The products are mainly used on 3C industry,lighting decoration,electrical appliances,auto parts,furniture parts,electric tool,medical equipment, intelligent automation equipment and so on.

The company was founded in 2010, has 10 years’ experience about development and manufacture management. It has more than two dozen patented technologies (including two invention patents) and was recognized as a national high-tech enterprise in December 2017. We have obtained ISO9001:2015 Certificate in May 7th, 2012.

Our company's production workshop consists of mould department, die-casting department, processing department, CNC department, paint department, etc. It has 12 professional die design engineers, senior mould making technicians, die-casting engineer, and CNC programmers.

Not the best, only better! We hope we’ll be the one of the hardware casting specialists. Welcome to pay a visit to our company.

-

China factory custom-made shockproof 21.5-inch LCD elevator display

-

Computer software w in10 w10 100% online computing system license key 10 professional OEM key high quality 10 enterprise key

-

Conference System Electric Projector Hanger Lift Belt Universal brTV Ceiling Lift Video Electric TV Lift Ceiling Mounting Design

-

10m/25m/40m/70m large screen interactive equipment radar eye dance floor interactive sensor radar touch sensor control software

-

Interactive Projection Desktop Object Recognition 3D Touch LED Desktop Smart Display AR Dynamic Digital Art Virtual Video

-

New Design Stainless Steel Projector/Laptop Cart/Projector Stand

-

Telon Mobile Electric TV Lift Floor Stand Rolling TV Cart for Flat Panel TVs 32 to 70 Inch with Wheel Stand

-

Ultra-narrow bezel multi-video wall panel, floor-to-ceiling digital signage LCD splicing screen

-

Wholesale Universal Projector Stand Cancel 43-65cm White Projector Ceiling/Wall Mount

-

Adjustable length projector ceiling mount

Other Products

-

$0.90 - $1.20 / piece

$0.90 - $1.20 / piece -

$0.90 / piece

$0.90 / piece -

$3.20 / piece

$3.20 / piece -

$2.38 / piece

$2.38 / piece