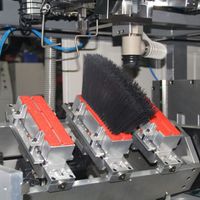

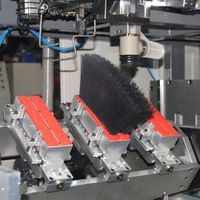

High speed cnc 2 colors 5 axis special holes toothbrush machine tufting machine for tooth brush making

-

Supplier: Guangdong Chuangyan Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Mr Jan LI -

Price: $20000.00 /set -

Min. Order: 1 set

| Control System: | CNC Controller; | Supply Ability: | 20 Unit/Units per Month; |

| Dimension(L*W*H): | 1250*1200*1340(mm); | Brake Motor: | Japanese Fuji; |

| Spinder Quantity: | 5 Axis; | Certification: | Patent Certificate; |

| Port: | SHNATOU; | Payment Terms: | L/C,T/T,Western Union,MoneyGram,Cash payments for offline orders.; |

| Packaging Detail: | EXPORT WOODEN PACKING; | Voltage: | 380VAC/220VAC; |

| Production Capacity: | 750Holes/min; | Automatic Grade: | Automatic; |

| Computer: | Touch Screen LCD; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Condition: | New; | Warranty: | 1 Year for nn-artificial damage; |

| Power(W): | 2.2KW; | Application: | Make Toothbrush; |

| Place of Origin: | Guangdong China; | Brand Name: | Chuangyan; |

| Function: | Toothbrush tufting; | Driving Motor: | Japanese Fuji; |

| Main Speed Control: | Automatic Frequency Control Circuit; | Weight: | 900kg; |

| Automatic Grade: | Automatic; |

Intelligent NC Computer Part

Features:

1) The introduction of Germany CNC technology research and development of intelligent numerical control touch screen LCD computer scanning hole coordinates.

2) American import NC CPU chip, speed P4 and dual core.

3) Automatic tracking speed.

5) The system is stable and reliable, adapting to different environments.

6) The whole closed loop system, strong anti- interference ability.

7) Upgrade to maximum tufting number of 99 holes.

8) Can be point to upgrade to add wool implement.

Servo Motor Part

Features:

1) XY axis worktable and handle change adopt japanese imported high precision servo motor.

2) German imported precision level C1 double thread ball screw.

3) Fast displacement: 820holes/min, hole-jumping distance can reach to 8-10mm.

4) Rigid soft stability and reliability.

Automatic Holes Scanning Coordinate Part

Features:

1) High-tech infrared automatic scanning brush handle hole coordinates.

2) High efficiency in changing product: 40 holes for about 5 minutes.

3) High precision positioning coordinates: tolerance +/- 0.02 mm.

4) Easy to operate and learn with high scanning speed.

5) Less tedious steps: manual measuring pitch error precision fine tuning.

High Speed Tufting Part

Features:

1) The introduction of German technology research and development to jig.

2) German import materials plant garden, tufting cutter and tufting pole.

3) The tufting mouth and rod are made by imported vacuum processing and high-precision mirror spark technology with high hardness, good toughness and strong wear resistance.

4) Tufting machine precision machining process error value: +/-0.01mm

Tufting aperture: 1.2 to 3.0mm.

5) Strong stability and tension, high efficiency and not easy to loose filament.

Double Color Box Part

Feature:

1) Citing Germany technology automatic cycle pressure cylinder principle: high pressure uniform and adjustable.

2) Convenient adjustment adopts double dabbing cylinder filament neatly.

3) Color change using Japanese original servo motor, can support color change every two holes.

4) Electronically controlled brushing technology.

5) Tufting cutter takes filament with high stability, not thinly and not scatted.

Trimming Part

Feature:

Adding trimming device to reduce trimming process.

Nylon Rolling Handle-off Box Part

Feature:

Easy to land rubber toothbrush.

Pre-Sales Service

* View our factory.

* Inquiry and consulting support.

* Provide advice based on buyer funds budget.

* Toothbrush whole production line support.

* Introduction raw material suppliers

After-Sales Service

* Training how to install and operate the machine.

* Engineers available to service machinery overseas.

* 1 year non-human damage warranty on spare parts.

A: We are a factory of toothbrush machinery manufacturer.

2. Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Shantou City, Guangdong Province, China. Warmly welcome to your visit!

Airport: Jieyang Airport

High speed train: Chaoyang Station / Puning Station (2-3 hours from Shenzhen/ HongKong /Guangzhou)

3. Q: What is your terms of payment?

A: 30% deposit first, and 70% balance before shipment.

We'll show you the photos of the products and packages before you pay the balance.

4. Q: How long is the delivery time?

A: 30-40 days for tufting machine and trimming machine.

45-50 days for blister labeling packaging machine.

5. Q: What is the advantage of your products?

A: High-tech, competitive price, superior after-sale service and whole production line of machinery and raw materials.

-

3 axis brush making machine/comb brush making machine/comb making machine

-

Brush machine automatic drilling broom brush making machine

-

Brush Machines Shoe Cleaning Handles Varnish Sticks Drilling and Tufting Wooden Broom Making Machines

-

CNC toilet brush tufting making machine for making brush sanding machine

-

Disposable eyelash brush production machine brush making machine for eyelash brush manufacturer

-

Manual Plastic Toilet Brush Making Tufting Machine Wooden Hair Brush Machine Steel Belt Custom Logo

-

CNC 3 Axis 3 Heads 2 Drilling and 1 Brush Sweeper High Speed Production Machine

-

Machine for the production of high-speed brooms

-

5 axis 2 drill 1 tufted high speed beautiful toilet brush making machine can be purchased

-

Industrial Brush Making Machine Automatic Broom Shoe Brush Hair Drilling Making Machine

Other Products

-

$10000.00 / set

$10000.00 / set -

$20000.00 / set

$20000.00 / set -

$20000.00 / set

$20000.00 / set -

$25000.00 / unit

$25000.00 / unit