Automatic Industrial Potato Chips Making Machine For Production Line

-

Supplier: Gongyi Guoxin Machinery Factory (General Partnership) -

Region: Henan, China -

Contact: Mr Jack Lee -

Price: $14000.00 /set -

Min. Order: 1 set

| Application fields: | Vegetable processing plant,Fruit processing plant,Snack food factory,Beverage Factory,potato processing; | Certification: | CE ISO; |

| Dimension(L*W*H): | Customzied; | Certification: | ISO9001,CE; |

| Raw material: | Fruit,Vegetables,potato; | After-sales Service Provided: | Field maintenance and repair service; |

| Function: | Automatic,Semi-automatic; | Machinery Function: | potato chips making machine; |

| Port: | Qingdao,Shanghai,as your require; | Transportation: | Shipping; |

| Output product name: | potato chips, french fries; | Place of Origin: | Henan China (Mainland); |

| Material: | Stainless Steel; | Weight: | 1500kg; |

| Supply Ability: | 15 Set/Sets per Month potato chips making machine has storage; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,potata chips making machine can be paid by Escrow,Credit Card; |

| Voltage: | 220V/380V; | Power Supply: | Electric; |

| Brand Name: | Guoxin; | Name: | Automatic Industrial Potato Chips Making Machine For Production Line; |

| Warranty: | 1 Year; | Condition: | New; |

| Application: | potato chips making machine; | Power(W): | 68.2; |

| Packaging Detail: | potato chips making machine can be put into standard container 20GP with wooden case; | Usage: | potato chips making machine; |

| Payment: | T/T,L/C; |

Potato Chips Making Machine

Brief introduction of potato chips making machine:

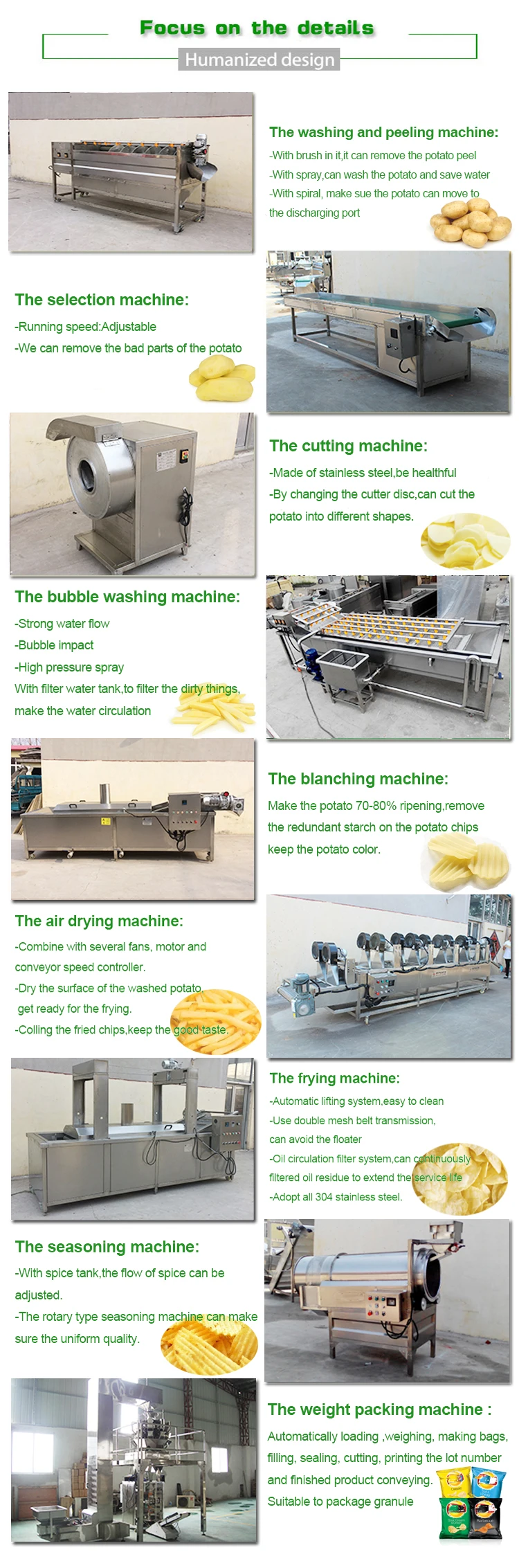

The automatic potato chips making machine is mainly used to make potato chips and othe fried snack food.The automatic potato chips making machine is made up of cleaning and peeling machine,cutting machine,blanching machine,dewatering machine,frying machine,deoiling machine,seasoning machine and packing machine.You also can add elevators to potato chips making line to make your work easier .

The flow chart of the potato chips making machine :

The detail of the automatic potato chips making machine price:

The parameter of potato chips making machine:

The attention of potato chips making machine:

Best raw material (potato) suggestion

Oval in shape Dry material content≥20% Sugar content≤0.4%;

Length ≥68mm Color outside is yellow Color inside is white

Less and small bud hole

Equipment and components

1. Hoist

Used to preclean potato,soften the potato peel, then hoist potatoes into washing and peeling machine.

2. Washing and peeling machine

This machine is used to peeling potatoes with hard brush and emery brush; Uneven and corrugated brush can peel the potatoes completely.

3. Selection machine

This machine is used to pick out potato eyes and dark parts on potatoes by manually.

4. Potato cutter

This machine is used to cut potato into sticks, french fries quality depends on fries length and shape, so cutting machine is very important.

6. Bubble washing machine

This machine used to washing potato starch and protect potato from oxidation, keep its original color.

7. Blanching machine

This machine is used to deactivate the activity of the oxidase, take off the overmuch starch, separate out the reducing sugar, also after blanching,it will get inner soft taste of french fries.

8.Air drying machine

Used to remove water,drying for frying.

9.Continuous frying machine

The frying time is 2-5minutes at the frying temperature is 170-180 ℃for potato chips;

Frying temperature is about 180-190 °C, and the frying time is about 1 minutes for frozen French fries.

10.Air drying machine:

Use fan to blow off the water on stick surface, then deliver sticks into the freezer.

11. Conveyor

Used between air dying machine and seasoning machine.

12. Seasoning machine

Use curry and spicy and so on. It is about 1.5—2.0%.

13. Automatic weighing and packing machine

Used to pack the french fries potato chips automatically .

Pre-sale services:

1) Select suitable equipment model.

2) Design and manufacture products according to clients’ special requirements.

3) Train technical personnel for clients.

4) Professional suggestion for customer.

Services during the sale:

1)take photos(including raw material, semi-products, final products, and loading products)

2) Pre-check and accept products ahead of delivery.

3) Prepare all clearance documents, so that the customer clearance smoothly.

After-sale services:

1) Provide civil engineering drawings of the equipment.

2) Free training(including installation,maintenace) to every customer.

3) Install and debug the equipment, ensure the drying running smoothly.

4) Examine the equipment regularly.

Why choose Guoxin?

1. Best price

We are the professional manufacturer of CE ISO certification potato chips making machine.

2. High quality

We have excellent technicain team. There are serious and responsible productin staff, quality control people to guarantee the quality of garlic drying from Guoxin Machinery Factory.

3. Before-sales and After-sales service

Before sales, welcome to visit our factory at any time. When you arrived China or Zhengzhou, you can call me (0086-15838133031) or email me.

4. Company qualification

We have independent import and export qualification. Our production get though the CE and ISO Certification.

If you are interested in the potato chips making machine, just feel free to contact me.

Jolina From Gongyi Guoxin Machinery Factory

Tell:0086-371-68533618

Phone:0086-15838133031

Whatsapp:+8615838133031

Skype:+8615838133031

Wechat:405530900

-

Fully automatic potato chip production line frozen potato chips making machine

-

Factory Price Potato Chips Production Line Fresh French Fries Making Machine Potato Chips Processing Factory

-

HORUS High Quality Automatic Potato Chips Making Machine Potato Shredded Machine

-

Fully Automatic Frozen French Fries French Fries Making Machine Production Line For Sale

-

Tornado manual potato machine made of stainless steel

-

Industrial 300-1000kg/hour Fully Automatic Potato Chips Production Line/Potato Chips Making Machine

-

French fries production line 1/4 Frozen machine

-

400kg/h Automatic Frozen French Fries Production Line Price

-

Potato Chips Production Line Vacuum Frying Potato Chips Maker Batch Fryer

-

High Quality Pringles French Fries French Fries Processing Equipment Potato Chips Production Line Manufacturing Machine Price

Other Products

-

$20000.00 / set

$20000.00 / set -

$20000.00 / set

$20000.00 / set -

$30000.00 / set

$30000.00 / set -

$40000.00 / set

$40000.00 / set -

$8000.00 / set

$8000.00 / set -

$18000.00 / set

$18000.00 / set -

$1000.00 / set

$1000.00 / set -

$18000.00 / set

$18000.00 / set -

$18000.00 / set

$18000.00 / set -

$1500.00 / set

$1500.00 / set