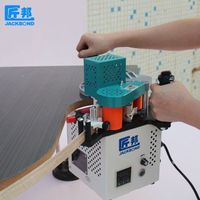

368A Reverse Direction Feeding Wood Working Automatic PVC Banding Edge Machine from China

-

Supplier: Foshan Shunde Lunjiao LZJ Woodworking Machinery Factory -

Region: Guangdong, China -

Price: $9000.00 /set -

Min. Order: 1 set

| Weight: | 1500KG; | Voltage: | 0.6Mpa; |

| Working Pressure: | 0.6Mpa; | Panel Thickness: | 12~60mm; |

| Overall size: | 4600*1000*1600mm; | After-sales Service Provided: | Online support; |

| Dimension(L*W*H): | 4600*1000*1600mm; | Place of Origin: | Guangdong China; |

| Certification: | CE; | Selling Units: | Single item; |

| Total power: | 9.5KW; | Brand Name: | LZJ; |

| Power(W): | 9.5kw; | Panel width: | ≥ 80mm; |

| Single gross weight: | 50 KG; | Package Type: | Our 368A Automatic PVC banding edge machine use Film Packing and fix into container with steel wire. Plywood package is also available against your request.; |

| Weight: | 1500kg; | Edge Thickness: | 0.4~3mm; |

| Warranty: | 1 Year; | Single package size: | 50X60X60 cm; |

| Condition: | New; | Applicable Industries: | Furniture factory; |

| Feeding Speed: | 12~20mn/min; |

Our banding edge machine adopt imported and famous brand for the main parts, to ensure the high quality and guarantee machine works more stable and durable.

| 368A Woodworking Automatic PVC Banding Edge Machine Specification |

| Working Pressure | 0.6Mpa |

| Panel width | > 80 |

| Panel Thickness | 12~60mm |

| Edge Thickness | 0.4~3mm |

| Feeding Speed | 12~20mn/min |

| Total power | 9.5kw |

| Overall Size | 4600*1000*1600mm |

| Weight | 1500kg |

(1) PLC:Delta (2) Electric parts:Schneider (3)Touch screen:Delta (4)Inverter:Delta

(5)Cylinder:Airtac (6)Conveyor:CPG (7)High speed motor:CC

Functions: Pre-milling / End Cutting/ Rough Trimming/ Fine Trimming/ Flat Scraping / Buffing

Products advantage detail:

Strong machine body

Strong machine body to reduce shaking to make banding effects better.

Horizontal plate thickness:12mm

Vertical plate thickness:6mm

Pressure relief value Automatic filling oil system

End cutting device with pressure relief value. Automatic filling oil system make

Its function is automatic release pressure to operating simple and save time, at

make right cut motor go down automatically, same time ensure linear guide more durable.

Daily maintenance

1. Comprehensive upgraded with pneumatic adjustmend door, slow down board feeding speed to avoid collision by too fast artificial feeding.

2. End cutting with impermeator for lubrication.Improve parts useful life,assure machine stability.

3. Front and rear end cutting with special high frequency and high speed motor, special flexible cable which can fold 15 million times.

4. Each motor can independently adjust the trimming Angle

5. Fine trim and rough trim can be upgraded to pneumatic automation knife, edge band switch can be on the touch screen one-button switch to replaced manual adjustment, improve production efficiency.

6. With automatic blowing, can remove residue after edge scraping

Product Application:

Contact Person:Daniel Liu

Mb:+86-18665405636(Same this no. for Whatsapp and Wechat)

Add:Plant 6,No.7-1,Xiashi Ind.Zone,Yangda Road,Xiashi,

Lunjiao,Shunde,Foshan,Guangdong,China

Tel:+86-757-23620465 Fax:+86-757-23620150

-

LB802 woodworking mini automatic PVC edge banding machine MDF panel furniture wood edge banding machine price

-

SINO F200MAX hot sale high quality automatic edge banding machine edge banding machine diy through feed edge banding machine

-

Speed adjustable portable small round plate edge banding machine edge press machine

-

45 degree high map automatic edge banding machine

-

MY07C Automatic Woodworking Edge Banding bander Machinery for 3mm edge banding wood

-

Straight Automatic Edge Banding Machine with Pre-milling for Furniture

-

Mould door skin hot press machine for different size wood door

-

automatic pvc mdf edge banding machine woodworking for wood

-

MY06D Furniture portable pvc melamine automatic wood manual edge banding machine

-

small manual edge banding machine

Other Products

-

$14700.00 / set

$14700.00 / set