gravimetric feeders for plastic masterbatch

-

Supplier: Dongguan Mitex Automation Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Jess Wang -

Price: $5800.00 /set -

Min. Order: 1 set

| Place of Origin: | Guangdong China; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Payment Terms: | L/C,D/P,T/T,Western Union; | Power(W): | 0.09KW; |

| additive hopper volume(L): | 32; | Applicable Industries: | plastic moulding; |

| Application: | Plastic process; | Supply Ability: | 200 Set/Sets per Month; |

| mixing capacity(kg/hr): | 50; | Packaging Detail: | wooden case packing; |

| Warranty: | 12 months; | Condition: | New; |

| batch weight(kg): | 0.5; | Brand Name: | Mitex; |

| main ingredient mixing range(%): | 5~100; | additive mixing range(%): | 0.05~10; |

| Voltage: | 220V single phase; | hopper volume(L): | 32; |

| power: | 0.09kw; | Certification: | CE; |

| Weight: | 130KG; | Dimension(L*W*H): | 1395X790X770; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | agitation vat volume(L): | 20; |

| Port: | shenzhen; | power supply(V/HZ): | 1PHASE230/50; |

| Production Capacity: | 50KG/Hour; | Automatic Grade: | Automatic; |

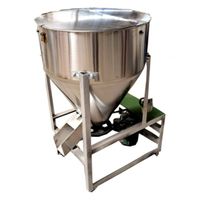

gravimetric feeders for plastic masterbatch

| Related Products |

Water-cooled chiller Air-cooled chiller Hopper Dryer |

Dehumidifier Water type MTC Oil type MTC |

| FEATURES of batch Gravimetric Blender |

MMS-G series gravimetric feeders for plastic masterbatch can be used in the fields of injection moulding machines, blow moulding machines and extrusion lines for proportionally precise mixing of several types of material. This series machines adopt B&R PLC controller and latest ingredients calculation methods.The machine is controlled by an advanced microprocessor with a digital display that is simple to calibrate. The self-compensation and calibration function ensure accurate material dosing percentages. A high precision electronic weighing scale is used to ensure precise weighing of every batch and ensure accuracy to ± 0.1%~ 0.3%. There are 42 models available to be selected based on various materials and throughputs. (This series are not suitable for powder and sheet pieces weighing).

|

| Specifications of gravimetric feeders for plastic masterbatch |

-

Plastic sheet extrusion mixer

-

PP PE ABS CE Industrial mixer Vertical mixer with plastic granules

-

Factory direct sales high quality plastic vertical mixer

-

Best Price Vertical Plastic Color Mixer/Mixer

-

LESINTOR new PET PE ABS ribbon powder mixer mixer dry powder coloring machine

-

High Speed Vertical Plastic Mixer Plastic Weighing Mixer

-

Vertical plastic mixer 100 kg

-

Easy Clean Plastic Color Mixer Plastic Color Mixer

-

volumetric plastic mixer with color doser for extruder

-

Stainless steel vertical flat mouth mixer vertical spiral powder seasoning mixer

Other Products

-

$3200.00 - $5000.00 / set

$3200.00 - $5000.00 / set -

$5000.00 / piece

$5000.00 / piece -

$1200.00 - $1500.00 / set

$1200.00 - $1500.00 / set -

$500.00 / piece

$500.00 / piece -

$600.00 / set

$600.00 / set -

$5600.00 / set

$5600.00 / set -

$7000.00 / set

$7000.00 / set -

$5950.00 / set

$5950.00 / set -

$700.00 / set

$700.00 / set -

$1500.00 / set

$1500.00 / set