Trustworthy Plastic PET Bottle Waste Recycling Washing Machine

-

Supplier: Sichuan Union Technology Co., Ltd. -

Region: Sichuan, China -

Contact: Mr. Jack Zhou -

Price: $5099.00 /set -

Min. Order: 1 set

| Payment Terms: | L/C,D/A,D/P,T/T; | Warranty: | 1 Year; |

| Keywords: | PET Plastic Bottle Recycling Production Line; | Key Selling Points: | High Productivity; |

| Condition: | New; | Dimension(L*W*H): | 4000*1800*3800mm; |

| Place of Origin: | Sichuan China; | Brand Name: | YZJ; |

| Supply Ability: | 5 Set/Sets per Month Trustworthy plastic PET bottle Waste recycling washing machine; | Certification: | CE ISO9001; |

| Capacity: | 300/500/1000kg/h; | Name: | Plastic Pet Bottle Recycling Crushing; |

| Production Capacity (kg/h): | 850; | Automatic Grade: | Automatic; |

| Color: | White; | Packaging Detail: | Trustworthy plastic PET bottle Waste recycling washing machine is packed by stretch film packing and wooden box outside as customer's requirement, or nuke packed.; |

| Material: | SUS304 Stainless Steel; | Applicable Industries: | Manufacturing Plant; |

| Weight (T): | 5; | Material Processed: | Crushing-washing-drying; |

| Type: | PET Bottle Plastic Recycling Line; | After-sales Service Provided: | Video technical support,Field installation, commissioning and training,Field maintenance and repair service,Online support; |

| Plastic Type: | PET; | Voltage: | 380V; |

| Raw material: | PET; | Application: | PET Bottle Recycling; |

| Port: | shanghai/guangzhou/chongqing; | Final product: | Clean PET Flakes; |

Off-label machine

Off-label machine is a new type of plastic products and equipment specially designed and manufactured for removing labels from plastic bottles and removing caps.

higher productivity, better finished surface quality.

Conveyor

Conveyor is mainly used for the removal of the material after the bottle to the top of the device from the lower to another device to avoid manual feeding in order to reduce labor intensity, cost savings and improve work efficiency

Crushing and cleaning machine

Crushing and cleaning machine is a new type of crushing and cleaning equipment, which uses high-quality refined from carbon steel, mainly used for PET bottle material in addition to the standard to cover broken, cleaning.

Dry hopper

It is mainly used for the final charge of the finished product to replace the original manual fishing and add a cleaning and automatic high-speed dehydration function, so as to save the labor cost, improve the cleaning quality and save the energy consumption. At the same time, Supporting the formation of a higher level of automation assembly line production.

Note:

If the customer needs more product information, please click on the inquiry link, send inquiry.

1.Company Profile

Established in 1995

Covers more than 200,000 Square meters

Over 52% staff working for technology and marketing

12 elements of (yzj) group

Exports products all over the world.

Vision: To be the BEST S&T Enterprise in the field of plastic processing industry.

2.Technical skills

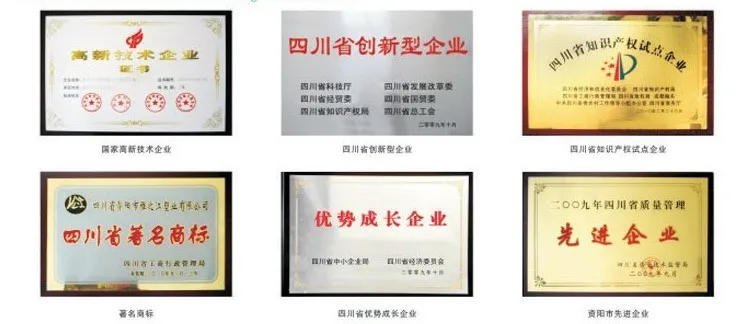

National High and New Technology Enterprise

Scientific and Technological Innovation Enterprises

Advantage of Growing Enterprise

Intellectual Property Experimental Enterprise

Famous Brand

Won more than 300 patents, the average annual patent more than 50 items

3.Team introduction

Over 52% staff working for technology and marketing

Technology Center

Marketing Center

Financial Center

4.Production scene

Mechanical workshop:

For the production of machinery and equipment, for customers to check machine equipment.

Plastic workshop:

We produce packing tape production equipment, while producing plastic packing tape.

5.Customer photo

Lebanon customer visit

Vietnamese customers visit

Egyptian customer visit

Egypt site installation and commissioning

Egypt site installation and commissioning

Sri Lanka site installation and commissioning

pre-sale service

1.Sample testing, cost estimates, samples (shipping borne by the customer), factory inspection test machine

After-sales service

1. Free installation and commissioning equipment, training operators, life-long equipment maintenance (paid), regular after-sales visits

2. Our service-line is offered 24 hours with a quick respond: respond within 12 hours for domestic customer, 20 hours for international customer.

FAQ:

Q1. Do you have equipment to see it live?

A: Yes. Welcome everyone's arrival.

Q2. Equipment delivery time?

A: The delivery time of equipment generally takes more than 30-60 days.

Q3. How to deal with orders?

A: Let us first know your request or application.

Second, we quote your request or our suggestion.

Third, the customer confirms the required equipment and deposits it into a formal order.

Fourth, we arrange production.

Q4: Do you provide product warranty?

A: Yes, we provide a one-year warranty for our products.

Q5: How to handle the error?

A: First of all, our products are produced under strict quality control system with a failure rate of less than 0.1%.

Second, during the warranty period (except for wearing parts), we solve the problem by phone or by video. For big problems, we will arrange technician on-site debugging.

Q6: After the purchase of equipment, to provide overseas installation and commissioning services?

A: Yes, we will arrange technical personnel to the site to install and debug.

※ All specifications and designs are subject to change without notice.

※ According to the customer's request.

If I am not online, please contact me by:

-

Sevenstars PET bottle recycling machine/plastic cleaning machine/plastic recycling equipment

-

Best Price Waste Plastic PP PE ABS PS PET Recycling Pelletizing Machine Recycling Plastic Pelletizing Machine Production Line

-

pp woven bag recycling cleaning line plastic cleaning recycling machine garbage recycling plant

-

Waste plastic recycling line PET bottle flakes crushing and cleaning production line

-

Waste recycling machine for plastic bottles/pp pe recycling line for washing hdpe flakes

-

Plastic Recycling Machine Cost / Plastic Recycling Plant / Recycling Plastic Pelletizer Price

-

PET bottle recycling machine/plastic washing machine/plastic recycling plant

-

Large capacity 2000kg/hr PET bottle recycling line

-

PP PE/PET Flake Washing Machine Floating Tank Floating Washing Machine for Plastic Recycling Washing Line

-

Polyester Fiber Recycled Making Machine/Waste PET plastic extruder machine/plant

Other Products

-

$24500.00 / set

$24500.00 / set -

$24500.00 / set

$24500.00 / set -

$62500.00 / set

$62500.00 / set